Steelmaking centralized control system and method based on industrial internet and medium

A technology of industrial Internet and centralized control system, applied in the field of steelmaking centralized control, can solve the problems of real-time data, data granularity reduction, etc., and achieve the effect of improving management efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

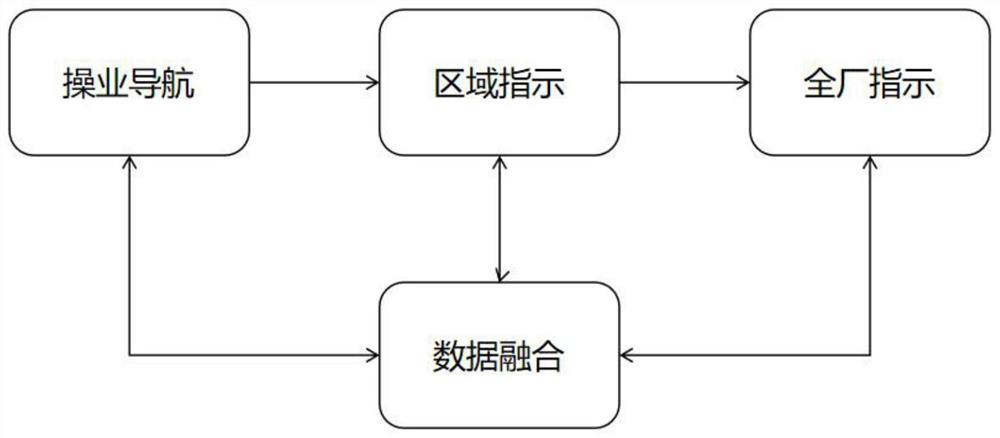

[0069] Such as figure 1 According to the industrial Internet-based steelmaking centralized control system provided by the present invention, it includes:

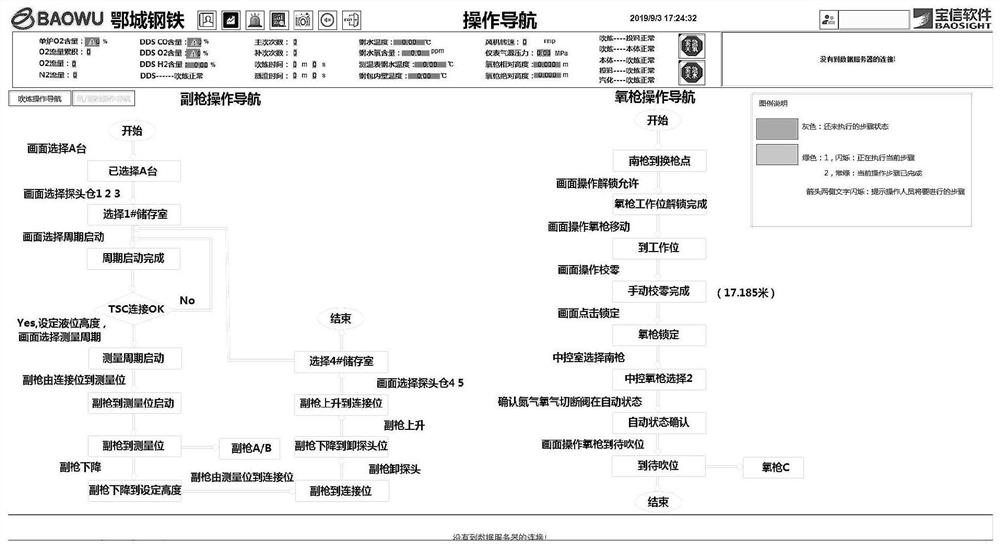

[0070] Operation navigation module: standardize production operations and operation procedures, and guide the operation of the centralized control center;

[0071] The operation navigation module is divided into six sub-modules including molten iron pretreatment, converter, LF furnace, refining furnace, slab continuous casting, and square billet continuous casting; each sub-module involves two aspects of production operation standardization and operation process standardization. Taking the module as an example, the production operation standard is divided into the following steps: equipment process standard, furnace opening and drying, smelting, slag splashing, furnace lining maintenance, fault handling, furnace shutdown and cleaning, and furnace dismantling, etc. 7 standard steps; The key operation process of the converte...

Embodiment approach

[0079] First of all, the analysis of steelmaking operations includes the analysis of the operating stations and operation specifications of each process before centralized control, the station planning after centralized control, and the conditions of auxiliary intelligent equipment. The analysis of steelmaking operations is divided into molten iron pretreatment, converter, refining, Continuous casting and other processes, taking the converter as an example, through the operation analysis of the converter front, rear, dust removal, vaporization and other operating stations, it is decided to enter the centralized control center first, the operating location, the change of operating authority, and the deployment of auxiliary intelligent equipment specified in the job specification.

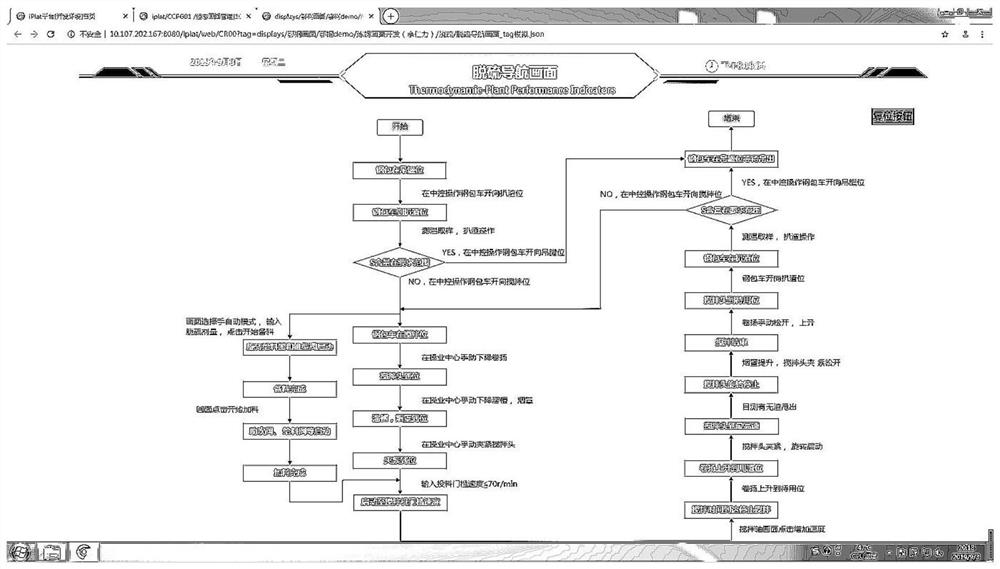

[0080] Secondly, the design of operation navigation, area instructions, and plant-wide instructions. Operation navigation and area instructions involve four processes including molten iron pretreatmen...

Embodiment 2

[0085] The steelmaking centralized control system based on the intelligent factory platform iPlat includes:

[0086] Intelligent factory platform: iPlat is an innovative platform for centralized control technology. The platform realizes the integration of process, equipment, operation, automation and information technology, and provides a platform for unified storage, access, data processing, analysis and intelligent linkage for cross-level business integration.

[0087] Steelmaking operation analysis: analyze the steelmaking job setting, responsibilities, job description, job planning after centralized control, and auxiliary conditions for intelligent equipment after centralized control, and clarify the operation process and specifications of the post before centralized control, and the operating place and authority after centralized control changes, changes in operating procedures and specifications, changes in the configuration of intelligent equipment after centralized cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com