Preparation method of graphene micro-wrinkle friction nano-generator

A nano-generator and graphene technology, applied in the direction of triboelectric generators, chemical instruments and methods, circuits, etc., can solve the problems of short service life and small friction area, and achieve good adhesion, increase friction contact area, and not easy to damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

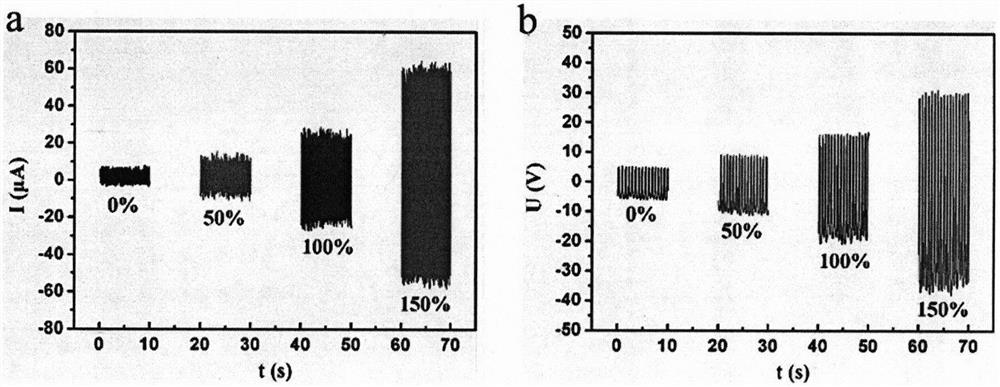

[0014] The steps to prepare shape memory polypropylene carbonate (SMPPC) / rGO microfolds by controlling the amount of recovery deformation are as follows: the two ends of the pre-stretched SMPPC / rGO film are clamped on the tensile machine, and the temperature is 40 °C (PPC glass transition temperature is about 30 °C). ), respectively controlled the recovery deformation of the film to 0%, 50%, 100%, and 150%, and then lowered the temperature to 5°C to fix the deformation, and made rGO microfolds with different shapes and sizes.

[0015] The steps of using SMPPC / rGO microfolds to construct TENGs are as follows: SMPPC / rGO microfolds are used as the positive electrode friction material, aluminum is used as the positive electrode, the negative electrode friction material is PVDF, and aluminum is used as the negative electrode. Wrinkled triboelectric nanogenerators. Finally, a constant force of 3N acts on the nanogenerator to test its output current and voltage. Performance test res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com