Photocatalytic hydrogen production device and hydrogen production system

A hydrogen production device and photocatalytic technology, applied in the direction of hydrogen, inorganic chemistry, hydrogen production, etc., can solve the problems of low efficiency of hydrogen production by solar energy, achieve the effect of improving the utilization efficiency of sunlight, increasing the overall efficiency, and increasing the ambient temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

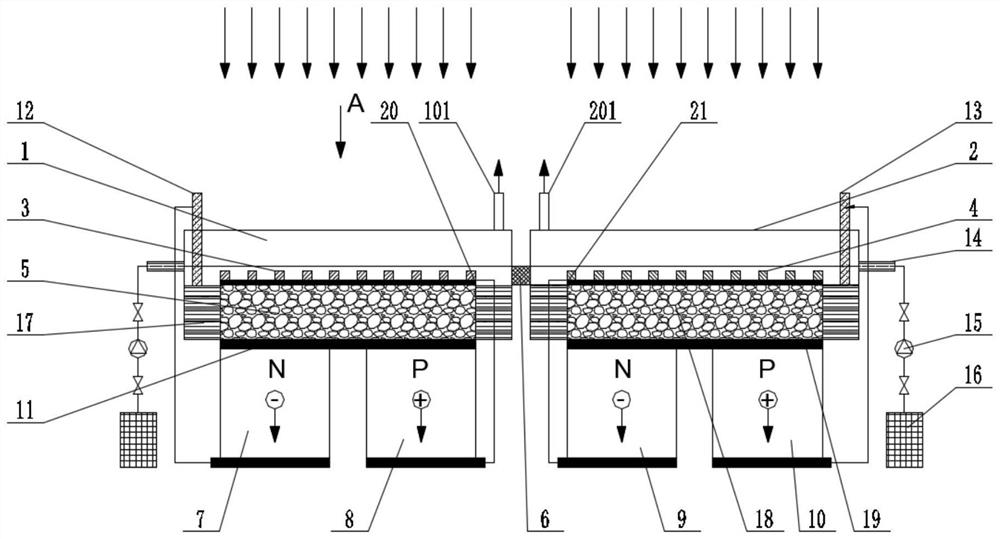

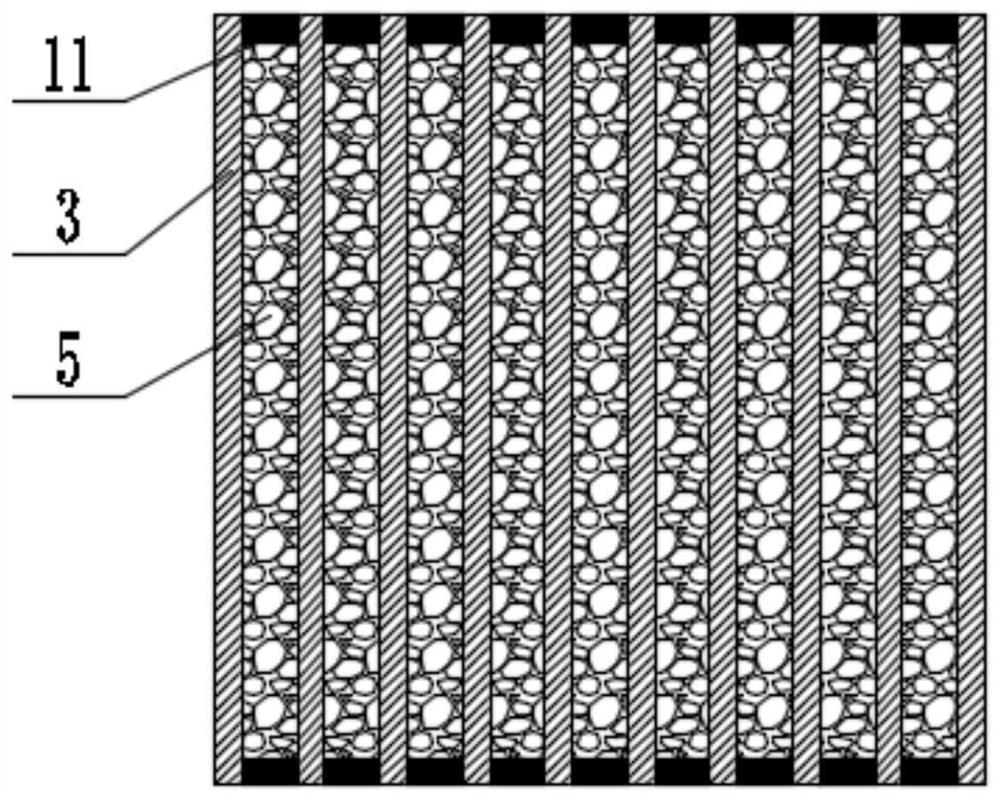

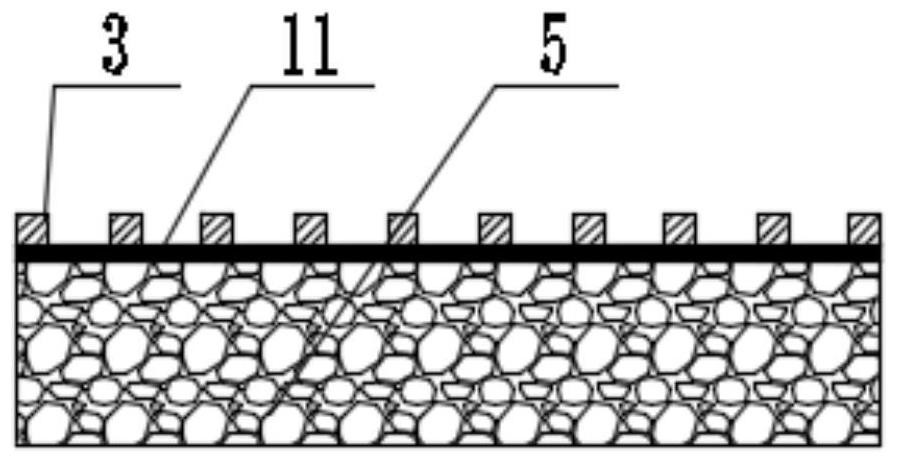

[0042] see Figure 1 to Figure 3 , in one embodiment, a photocatalytic hydrogen production device, comprising a light-gathering heat collection unit, an oxidation reaction photocatalysis unit, a reduction reaction photocatalysis unit, an electron mediator 6, a first thermoelectric power generation mechanism and a second thermoelectric power generation mechanism .

[0043] Among them, the light-concentrating heat-collecting part is used to collect sunlight and provide sunlight to the oxidation reaction photocatalysis part and the reduction reaction photocatalysis part, so that the oxidation reaction photocatalyst 3 and the reduction reaction photocatalyst 4 can be respectively Oxygen and hydrogen production.

[0044] The two ends of the electron mediator 6 are respectively connected with the water in the oxidation reaction photocatalysis part and the water in the reduction reaction photocatalysis part, and are used to transfer the photogenerated electrons generated by the oxid...

Embodiment 2

[0067] This embodiment provides a hydrogen production system, including the photocatalytic hydrogen production device in the first embodiment above. The solar light is collected and output to the oxidation reaction photocatalysis part and the reduction reaction photocatalysis part by setting the light concentrating heat collection part, and the photogenerated electrons generated by the oxidation reaction are transferred to the photogenerated hole combination of the reduction reaction through the electron mediator 6, Realize the closed-loop reaction; at the same time, the first thermoelectric power generation mechanism and the second thermoelectric power generation mechanism are respectively arranged under the oxidation reaction photocatalysis part and the reduction reaction photocatalysis part, and are in heat transfer contact with the two photocatalysis parts respectively; the first thermoelectric power generation mechanism and the The second thermoelectric power generation me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com