Variable polarity plasma arc welding pore suppression method based on spot cluster directional movement control and quality compensation

A directional movement, plasma arc technology, applied in the field of forming and manufacturing, to achieve the effect of large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

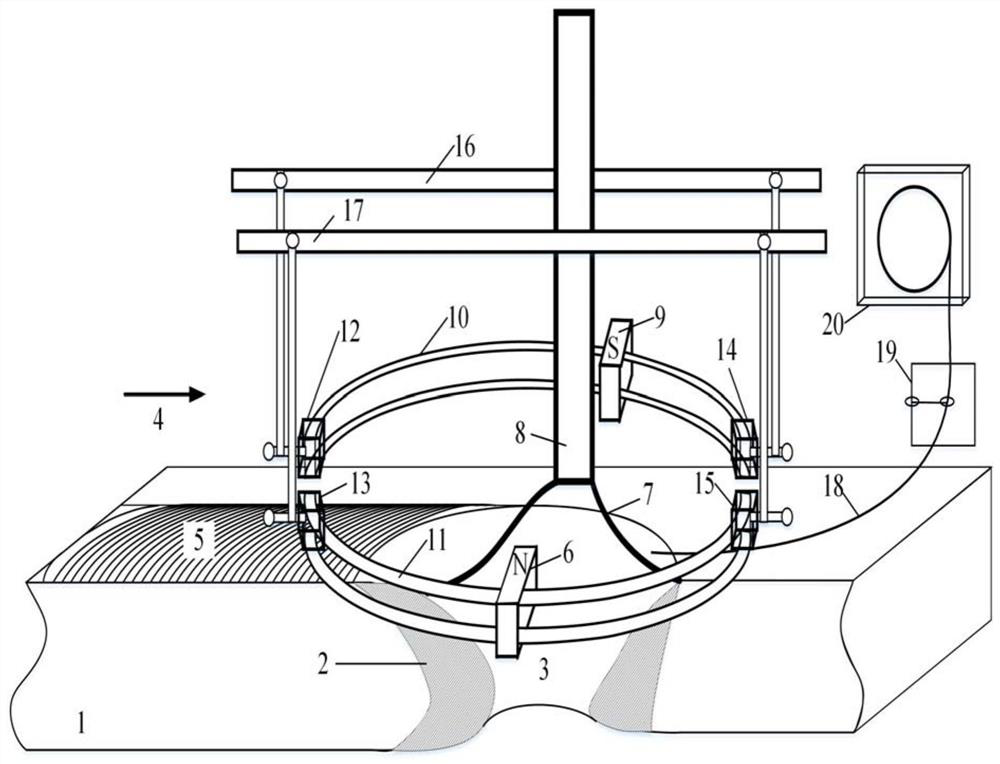

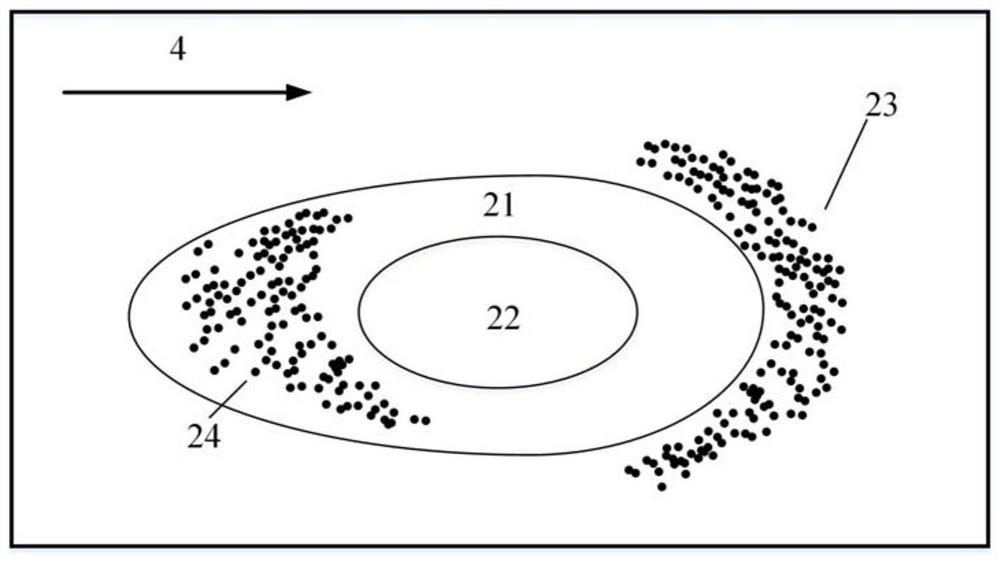

[0036] As shown in the figure, prepare an aluminum alloy base material 1 with a thickness of 5mm, connect the water circuit and gas circuit of the whole system, connect the polarity-changing plasma welding power supply, the welding torch 8 and the base material 1 through cables to form a circuit, and connect the magnetic field generator and the magnetic pole 6 and 9 are connected, adjust the wire feeding system 19 and 20, feed the welding wire 18 to the initial position, start the maintenance arc, turn on the main arc 7 after the maintenance arc is stable, and start the moving trolley after the workpiece is penetrated to form a small hole 3 Control the workpiece to move along the welding direction 4 according to the welding speed, and adjust the spatial position of the magnetic poles 6 and 9 through the angle and position adjustment devices 10, 11, 12, 13, 14 and 15, so that the cathode spots are clustered and moved to the front of the small hole 22 In the oxide film area, spot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com