Sewage pretreatment device and pretreatment method

A sewage pretreatment and sewage technology, which is applied in the direction of water/sewage treatment, water/sewage multi-stage treatment, water/sewage treatment equipment, etc., can solve the problems of low treatment efficiency and long time-consuming sewage pretreatment, and reduce swirling flow Influence, improve the flocculation effect, improve the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

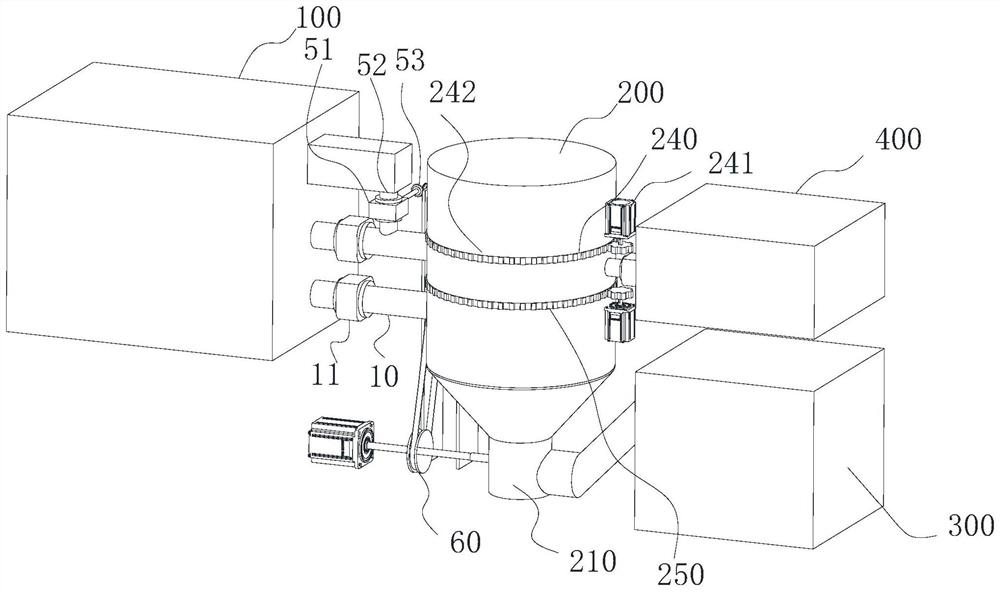

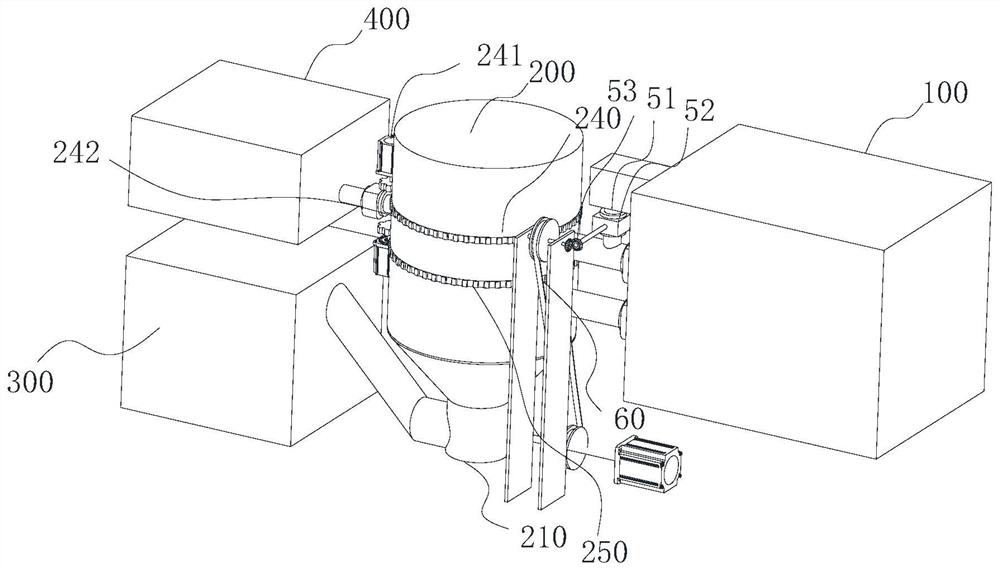

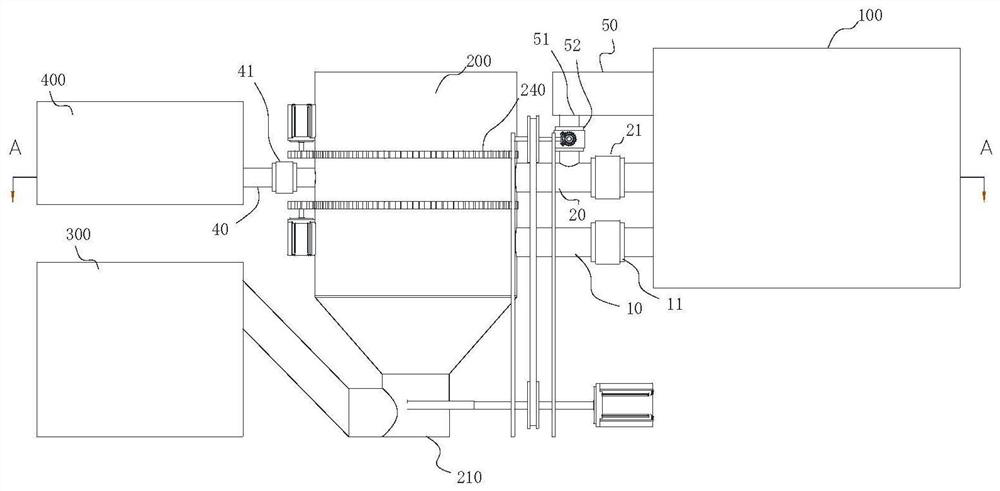

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings of the description and through specific implementation methods: the core content of the present invention is to combine the flocculation and sedimentation steps, and simultaneously take place in the settling tank 200, and it should be noted that other In the field of direct sedimentation and stratification after flocculation, it only corresponds to the flocculation step of the present invention, while the present invention is applied in the field of sewage treatment, and its characteristic is that the particle size is uneven. The original process is to completely stratify the large particles through sedimentation first. , and then carry out flocculation and stratification, and if flocculation and sedimentation are to be carried out at the same time, there will be a problem. The material with large particle density will stratify quickly, and flocculation needs reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com