Superfine tailing cemented filling soft soil curing agent and preparation method and application thereof

A curing agent and soft soil technology, which is applied in the field of superfine tailings cemented and filled soft soil curing agent and its preparation, can solve the problems of difficult to take into account the consolidation body and poor consolidation effect at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

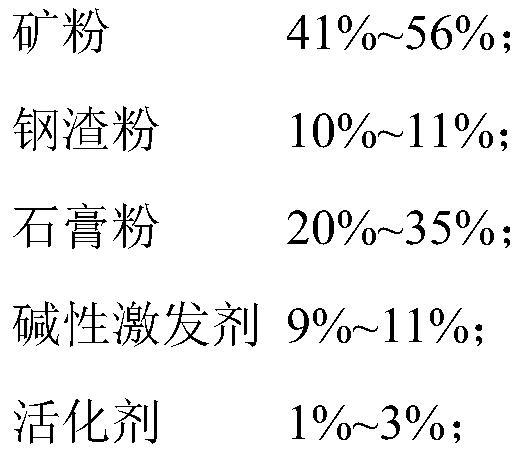

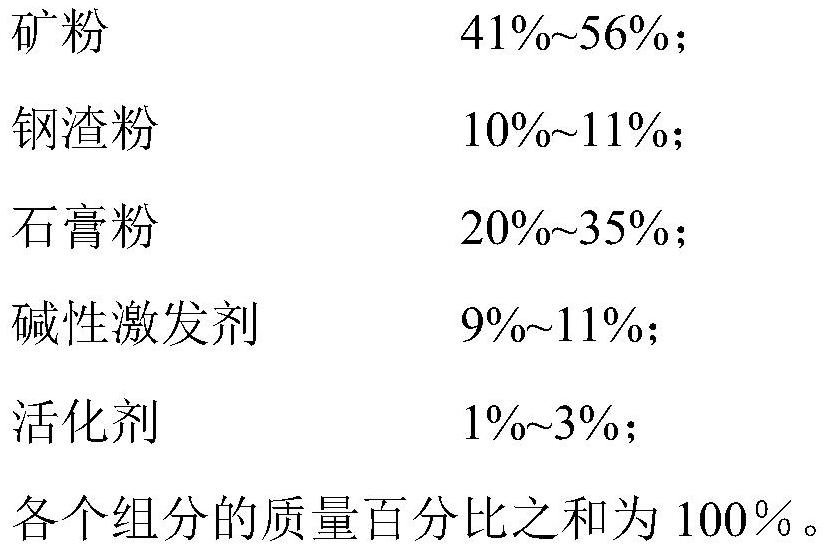

[0025] A method for preparing and applying a soft soil curing agent for cementing and filling ultra-fine tailings in Yinshan Mine of Jiangxi Copper Group. The method includes the following steps:

[0026] (1) Take a certain amount of the following raw materials according to mass percentage: 56% of mineral powder, 10% of steel slag powder, 20% of broken gypsum, alkaline activator (Conch brand 425 grade cement: Na 2 CO 3 :K 2 CO 3 =9:0.8:0.2) 11%, activator (triethanolamine: sodium lignosulfonate: calcium lignosulfonate = 3:3:4) 3%, crushed gypsum with indoor cement mill for 50 minutes to make gypsum powder, then add other raw materials into the ball mill, mix and ball mill for 15 minutes to obtain the soft soil curing agent;

[0027] (2) Take the tailings raw material to measure the water content, and weigh the soft soil curing agent, the original tailings and Tap water, add the weighed tailing sand and soft soil curing agent into the mixer and stir quickly, and add the wei...

Embodiment 2

[0031] A method for preparing and applying a soft soil curing agent for cementing and filling ultra-fine tailings in Yinshan Mine of Jiangxi Copper Group. The method includes the following steps:

[0032] (1) Take a certain amount of the following raw materials according to mass percentage: 56% of mineral powder, 10% of steel slag powder, 20% of broken gypsum, alkaline activator (Conch brand 425 grade cement: Na 2 CO 3 :K 2 CO 3 =9:0.8:0.2) 11%, activator (triethanolamine: sodium lignosulfonate: calcium lignosulfonate = 3:3:4) 3%, crushed gypsum with indoor cement mill for 50 minutes to make gypsum powder, then add other raw materials into the ball mill, mix and ball mill for 15 minutes to obtain the soft soil curing agent;

[0033] (2) Take tailings raw material to measure water content, weigh soft soil curing agent, original tailings and Tap water, add the weighed tailing sand and soft soil curing agent into the mixer and stir quickly, and add the weighed tap water while...

Embodiment 3

[0037] (1) Take a certain amount of the following raw materials according to mass percentage: 41% of mineral powder, 11% of steel slag powder, 35% of broken gypsum, alkaline activator (Conch brand 425 grade cement: Na 2 CO 3 :K 2 CO 3 =9:0.8:0.2) 11%, activator (triethanolamine: sodium lignosulfonate: calcium lignosulfonate=3:3:4) 2%, crushed gypsum with indoor cement mill for 50 minutes to make gypsum powder, then add other raw materials into the ball mill, mix and ball mill for 15 minutes to obtain the soft soil curing agent;

[0038] (2) Take the tailings raw material to measure the water content, and weigh the soft soil curing agent, the original tailings and Tap water, add the weighed tailing sand and soft soil curing agent into the mixer and stir quickly, and add the weighed tap water while stirring to ensure that the slurry is evenly stirred;

[0039] (3) Take a small amount of the uniformly stirred filling slurry to measure the expansion degree of the slurry to eva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Expansion | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com