Decorative ceramic tile using unfired glaze, and manufacturing process thereof

A production process and ceramic tile technology, which is applied in the field of building materials, can solve the problems of poor decoration effect and blurred printing patterns, etc., and achieve the effects of good decoration, enhanced adhesion and superior protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

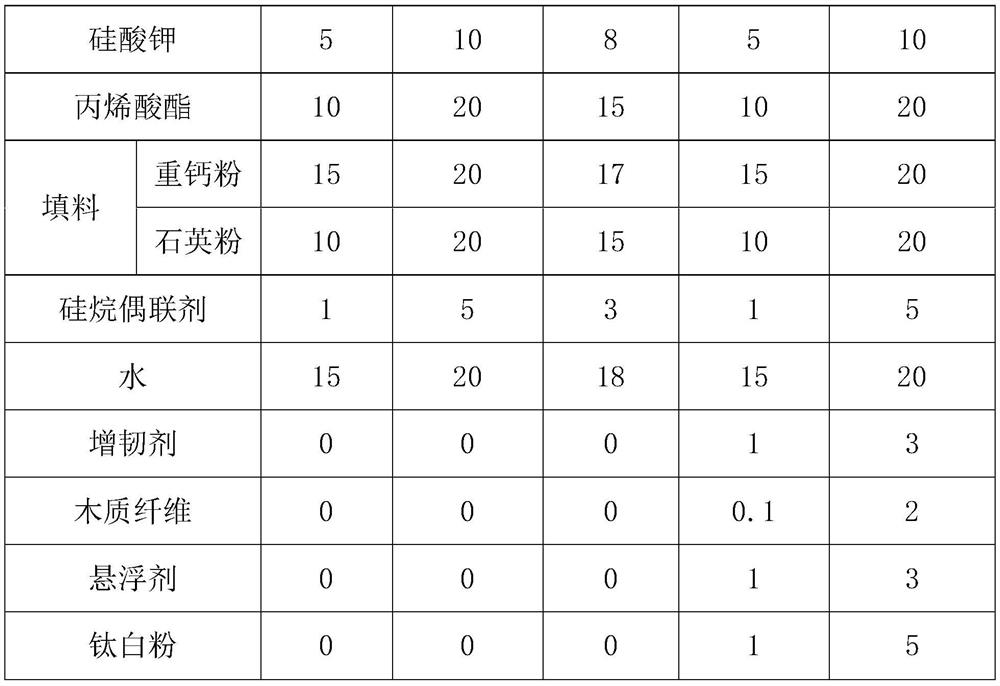

[0072] A manufacturing process of a decorative ceramic tile using an unfired glaze, comprising the following steps:

[0073] (1) Stir and mix the raw materials of the bottom layer slurry evenly, and the stirring time is 5min to obtain the bottom layer slurry, and the raw materials of the bottom layer slurry are prepared according to the proportioning in Table 1;

[0074] (2) Spray the bottom layer slurry on the surface of the calcined billet (the conventional calcined billet has a water absorption rate of 0.3%) on the surface of the calcined billet, and the spraying amount is 350g / m 2 , and then place the calcined billet sprayed with the bottom layer slurry at room temperature for curing for 30 minutes;

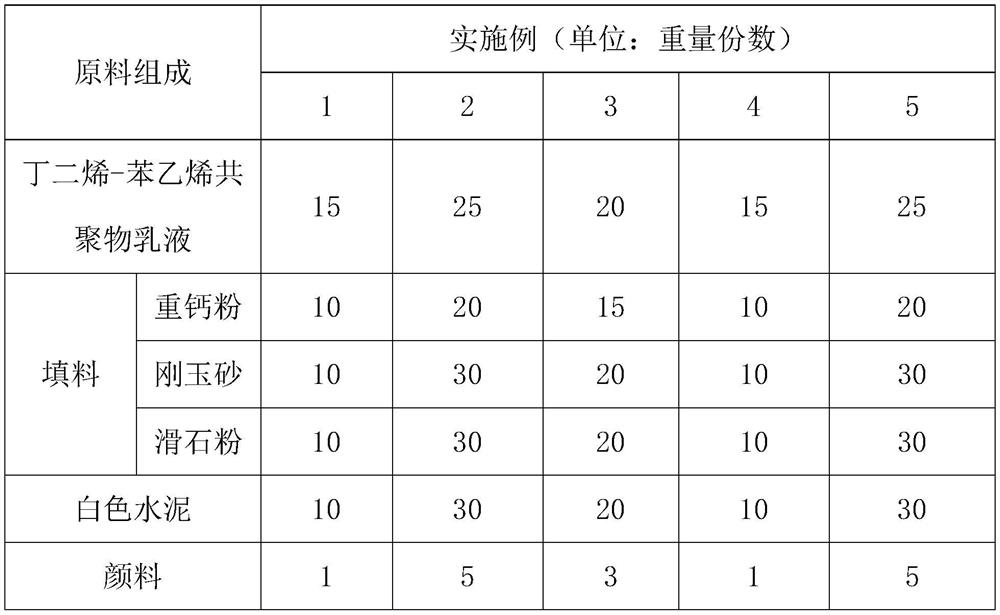

[0075] (3) Stir and mix the raw materials of the surface layer slurry evenly, and the stirring time is 5min to obtain the surface layer slurry, and the raw materials of the surface layer slurry are prepared according to the proportioning in Table 2;

[0076] (4) The surface ...

Embodiment 6

[0086] Compared with Example 5, in step (2), the spraying amount of the bottom layer slurry sprayed on the surface of the calcined billet is 200g / m 2 , in step (4), the surface layer slurry is used to print patterns on the surface of the calcined body by screen printing, and the printing amount is 250g / m 2 , the remaining formulations and preparation methods are consistent with Example 1, and a decorative ceramic tile using an unfired glaze is prepared.

Embodiment 7

[0088] Compared with Example 5, in step (2), the spraying amount of the bottom layer slurry sprayed on the surface of the calcined billet is 400g / m 2 , in step (4), the surface layer slurry is used to print patterns on the surface of the calcined billet by screen printing, and the printing amount is 350g / m 2 , the remaining formulations and preparation methods are consistent with Example 1, and a decorative ceramic tile using an unfired glaze is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com