Preparation method of capillary tube refrigeration device based on electrocaloric effect

A refrigeration device and electric card effect technology, applied in the direction of machines using electric/magnetic effects, chemical instruments and methods, refrigerators, etc., can solve the problem of insufficient space utilization, achieve easy maintenance and replacement, improve density, Improve the effect of the composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

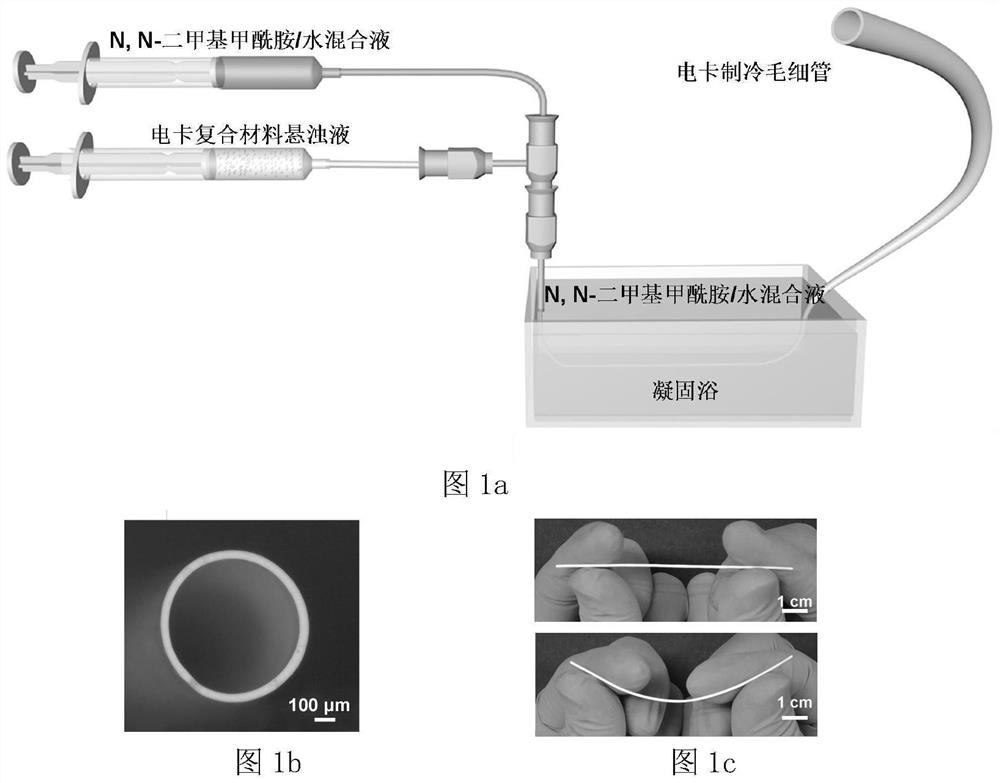

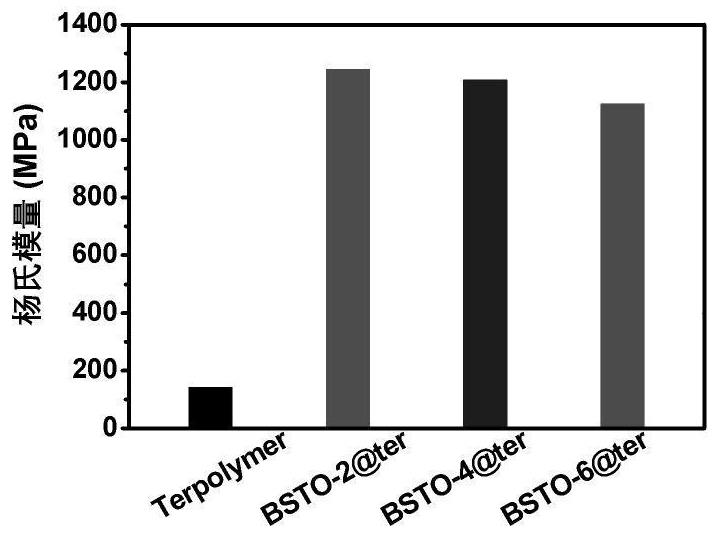

[0029] The present invention is by doping Ba in the preparation process of the relaxation ferroelectric polymer P (VDF-TrFE-CFE) 0.6 Sr 0.4 TiO 3 (BSTO), and prepare the capillary-shaped electric card refrigeration element in the mode of coaxial wet spinning, construct the magnetic drive refrigeration device, the preparation method of the capillary tube refrigeration device based on the electric card effect of the present invention is:

[0030] 1. Preparation of carbon nanotube dispersion

[0031] Disperse 5 mg of carboxylated carbon nanotubes in a mixture of 18 ml of isopropanol and 2 ml of deionized water, sonicate the probe for 1 h and centrifuge at 3500 rpm for 5 min, and take the supernatant as the carbon nanotube solution.

[0032] 2. Preparation of inorganic fillers and types of Ba with high breakdown electric field 1-x Sr x TiO 3 P(VDF-TrFE-CFE) Capillary

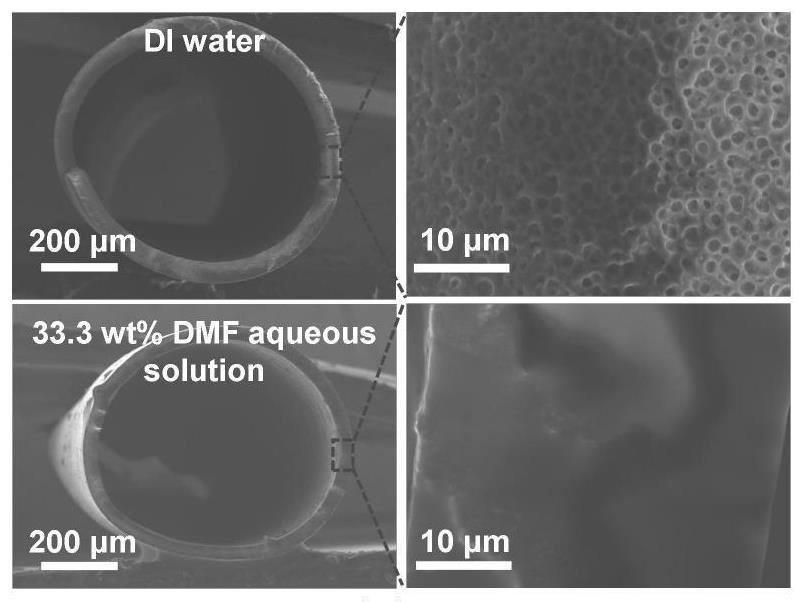

[0033] P(VDF-TrFE-CFE) powder, Ba 1-x Sr x TiO 3After mixing with N,N-dimethylformamide (DMF) according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com