Surrounding type secondary winding and fault-tolerant operation motor stator structure

A stator structure, wrap-around technology, applied in the shape/pattern/structure of the winding conductor, the shape/pattern/structure of the magnetic circuit, the prevention/reduction of eddy current loss in the winding head, etc. It can achieve the effect of realizing leakage magnetic energy storage, improving reliability and self-fault-tolerant operation, and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

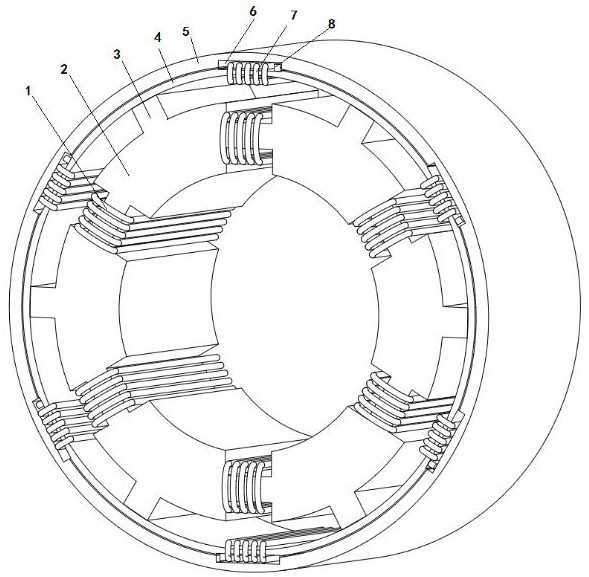

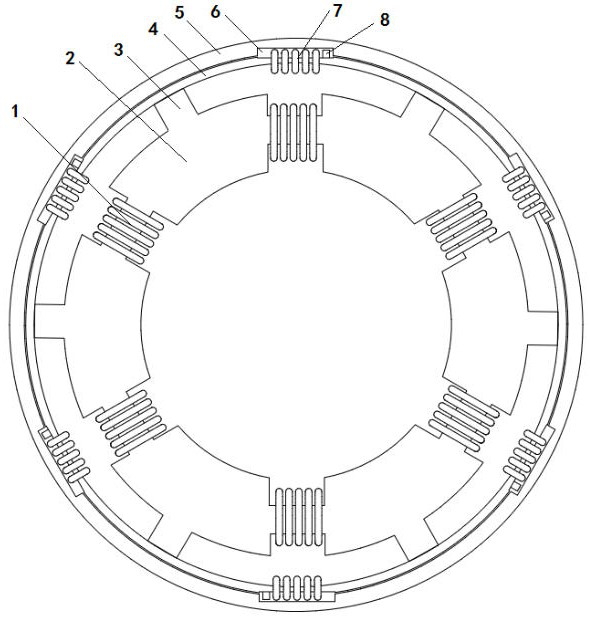

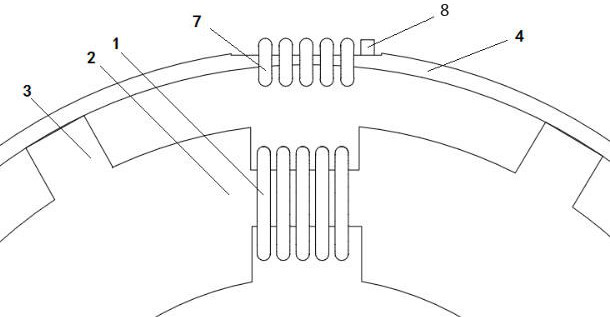

[0029] The specific implementation manner of this embodiment will be described in detail below in conjunction with the accompanying drawings, Figure 7 , Figure 8 , Figure 9 with Figure 10 Arrows indicate the direction of the magnetic field.

[0030] Such as Figure 1 to Figure 6 As shown, this embodiment discloses a surrounding secondary winding and a fault-tolerant motor stator structure, including a motor casing, a stator core 2 and a surrounding winding 1 .

[0031] The motor casing is a layered casing, which is nested by an inner casing and an outer casing. The inner casing is a magnetically conductive casing 4 made of a magnetically conductive material, and the outer casing is an ordinary non-magnetically conductive The non-magnetic casing 5 made of materials; the magnetic casing 4 is connected and fixed with the stator core 2 through the distributed magnetic connection columns 3 .

[0032] Both sides of each wrap-around winding 1 have magnetically conductive con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com