Flexible clutch based on electrostatic adsorption and preparation method thereof

A flexible clutch and electrostatic adsorption technology, applied in the field of flexible clutches, can solve problems such as low dielectric constant of dielectric materials, increased device risk, and inability to obtain force density, achieving good mechanical properties, high force density, and high relative The effect of dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Based on the problems existing in the prior art, such as figure 1 As shown in, the present embodiment provides a method for preparing a flexible clutch based on electrostatic adsorption, comprising steps:

[0042] S100. Take the MXene-DMF solution in the reactor, and add polymer into the reactor to obtain a composite solution.

[0043] Specifically, MXene-DMF solution can be obtained directly from the market, or can be obtained by mixing MXene powder with DMF solution. For example, Beijing Beike Nano New Material Co., Ltd. can provide a concentration of 3mg mL -1 MXene-DMF solution.

[0044] In an implementation of this embodiment, the concentration is 3mg mL -1 The MXene-DMF solution is placed in the reaction kettle, and the polymer is added into the reaction kettle, and treated with ultrasonic vibration to obtain a composite solution.

[0045] S200, coating the composite solution on the electrode layer, and drying to form an MXene / polymer dielectric film.

[0046]...

Embodiment 1

[0087] 1. Preparation of dielectric film:

[0088] Mix polyvinylidene fluoride-trifluoroethylene-trifluoroethylene (P(VDF-TrFE-CTFE)) powder with solvent N,N-dimethylformamide (DMF) at a ratio of 1g:7mL, and wait until P( After VDF-TrFE-CTFE) is completely dissolved, the solution is coated on the electrode layer with a coating thickness of 40 μm, and heated at 100° C. for 1 h until the DMF is completely volatilized to form a P(VDF-TrFE-CTFE) dielectric film. Such as Figure 5 shown.

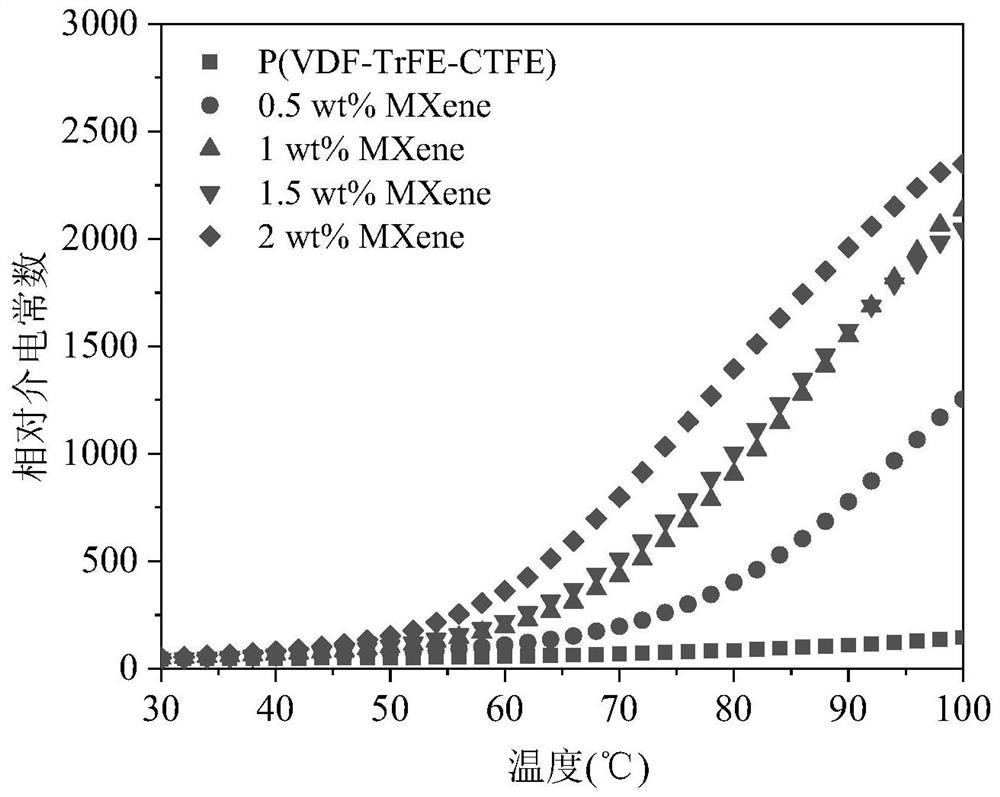

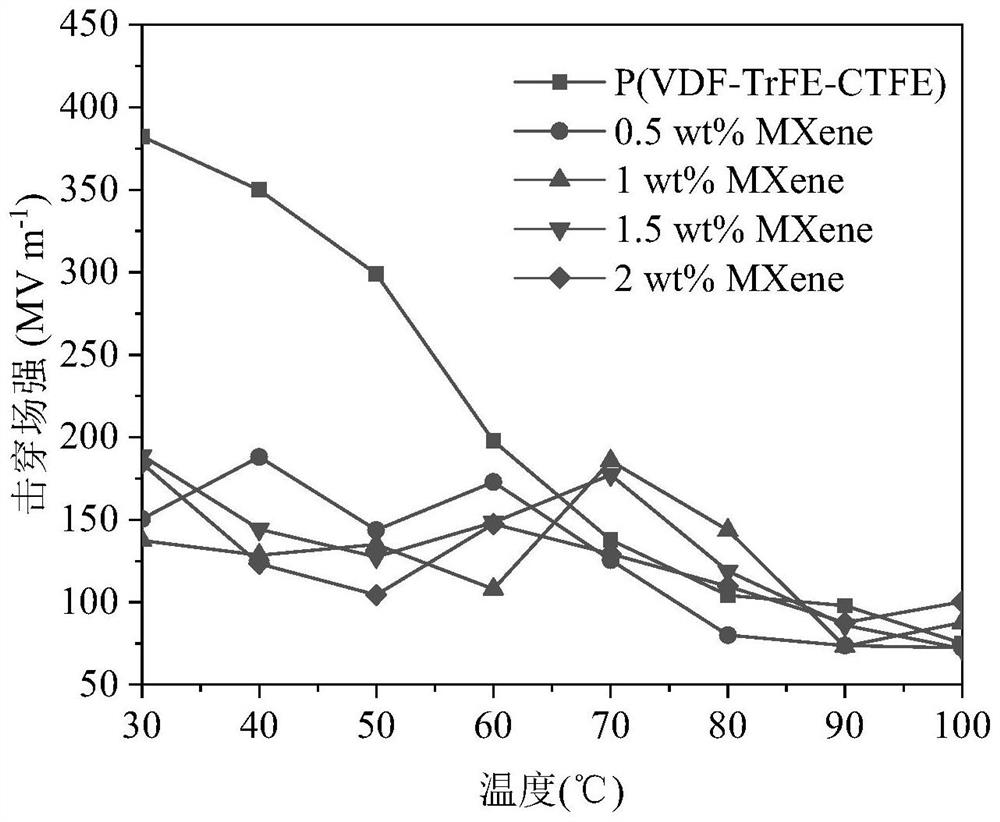

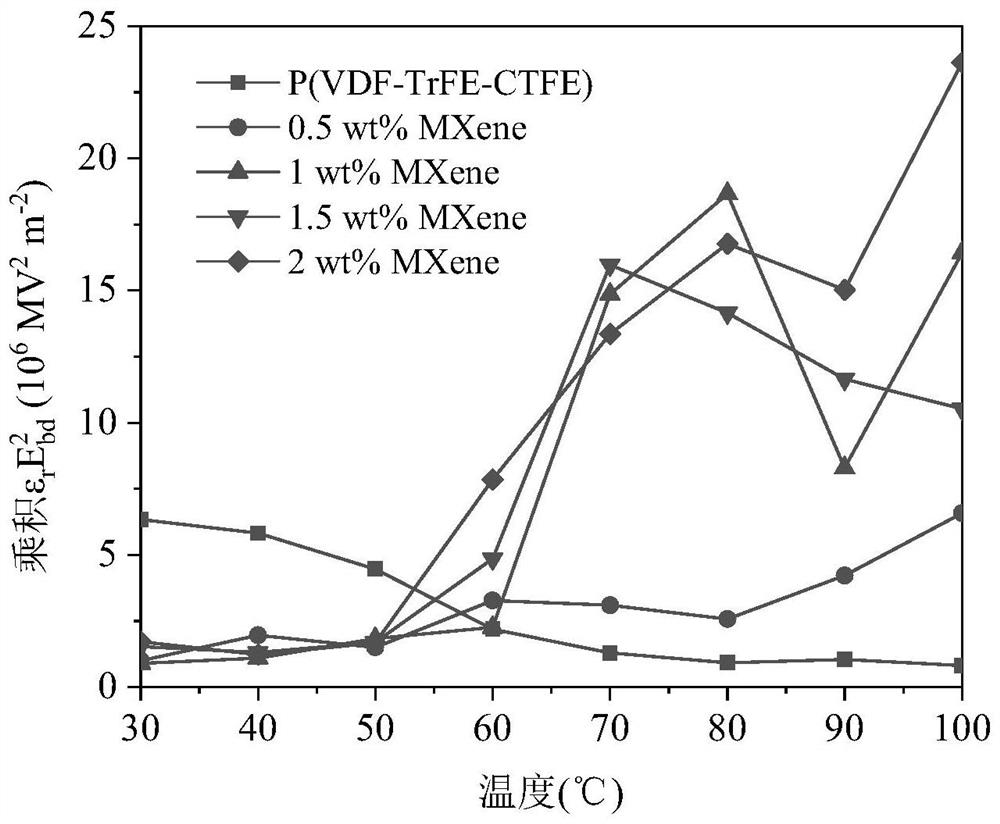

[0089] A small piece of P (VDF-TrFE-CTFE) dielectric film is torn from the electrode layer for relative permittivity and breakdown field strength measurement, the results are as follows figure 1 and as in 2, as in figure 1 As shown, the dielectric constant of the dielectric film formed entirely of P(VDF-TrFE-CTFE) is about 43 at room temperature, and it increases slightly with the increase of temperature. Such as figure 2 As shown, the higher the temperature, the breakdown field strength of...

Embodiment 2

[0097] 1. Preparation of dielectric film:

[0098] Take an appropriate amount of MXene-DMF solution in the reaction kettle, add P(VDF-TrFE-CTFE) to the MXene-DMF solution, and use ultrasonic oscillation for 2 hours to assist the dispersion of nanosheets, and obtain a composite solution after the mixture is completely mixed uniformly. The mass accounts for 0.5% of the total mass of MXene and P(VDF-TrFE-CTFE).

[0099] The composite solution was coated on the electrode layer with a coating thickness of 40 μm, and heated at 100 °C for 1 h until the DMF was completely volatilized to form a MXene / P (VDF-TrFE-CTFE) dielectric film. figure 1 and figure 2 As shown, at 100°C, the relative permittivity of the MXene / P(VDF-TrFE-CTFE) dielectric film reaches 1254, and the breakdown field strength is the same as that of the P(VDF-TrFE-CTFE) dielectric film under the same conditions Almost identical.

[0100] 2. Preparation of flexible clutch:

[0101] Such as Figure 6 As shown, with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com