Flue-cured tobacco cultivation method capable of reducing labor and cost, saving fertilizer and improving efficiency

A cultivation method and flue-cured tobacco technology are applied in fertilization methods, tobacco cultivation, botanical equipment and methods, etc., to achieve the effects of avoiding hypoxia, reducing exchange, and reducing water evaporation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

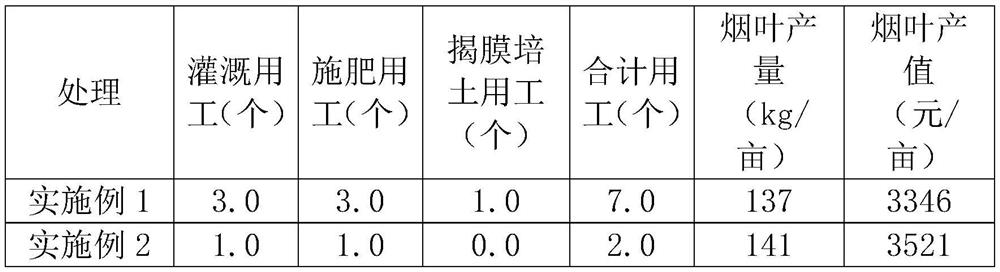

Embodiment 1

[0025] The test will be carried out in 2020. The test site is located in Dapo Township, Zhanyi District, Qujing City, Yunnan Province. The type of tobacco field is a mountain tobacco field.

[0026] According to (local conventional flue-cured tobacco cultivation method): do not return straw to the field during pre-planting; before transplanting flue-cured tobacco, make ridges and ponds, the height of the ridges is 20 cm, and the depth of the pond is 10 cm; no plastic film is used; fertilization is divided into three times: on the day of transplanting Apply 30% tobacco-specific fertilizer to the pond, then transplant flue-cured tobacco, apply 40% of the total amount of tobacco-specific fertilizer 35 days after transplanting flue-cured tobacco, and apply another 30% 45 days after transplanting flue-cured tobacco.

Embodiment 2

[0028] The test will be carried out in 2020. The test site is located in Dapo Township, Zhanyi District, Qujing City, Yunnan Province. The type of tobacco field is a mountain tobacco field.

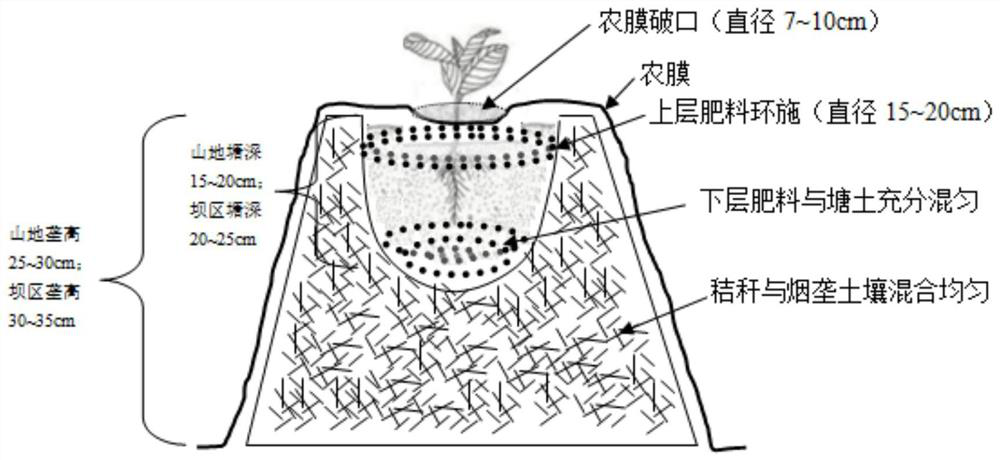

[0029] According to (the cultivation method of flue-cured tobacco of the present invention): before the pre-soil preparation, the wheat straw (5cm) of 600kg / mu is evenly sprinkled on the field, and then plowed; , the depth of the pond is 20cm; when fertilizing, first apply 50% of the fertilizer to the bottom of the pond (evenly mixed with the soil) and cover it with pond soil, and the other 50% of the fertilizer ring is applied near the inner side of the pond mouth (about 15cm in diameter); after fertilization is completed Cover with agricultural film, and break the film at the center of the smoke pond to open a large opening (opening 7cm), then transplant the tobacco seedlings and cover the roots with fine soil; the film covering period is from transplanting flue-cured tobacco to when the...

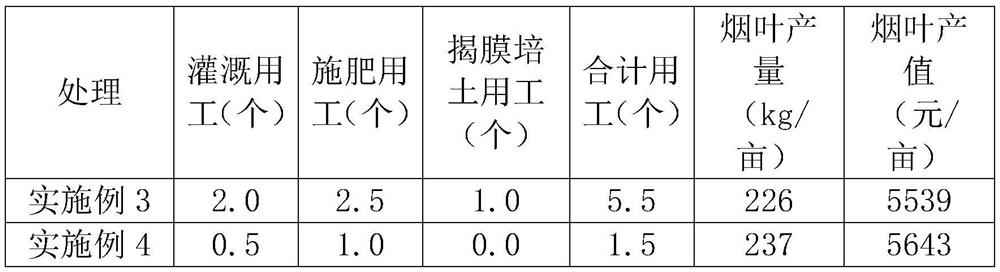

Embodiment 3

[0031] The test will be carried out in 2020. The test site is located in Zhaowei Village, Hongta District, Yuxi City, Yunnan Province. The type of tobacco field is Ba District Tobacco Field.

[0032] According to (local conventional flue-cured tobacco cultivation method): do not return straw to the field during pre-soil preparation; ridges and ponds are formed before transplanting flue-cured tobacco, the height of the ridges is 25cm, and the depth of the pond is 15cm; no plastic film is used; fertilization is divided into three times: on the day of transplanting Apply 50% tobacco-specific fertilizer to the mixing pond, then transplant flue-cured tobacco, apply 30% of the total amount of tobacco-specific fertilizer 35 days after transplanting flue-cured tobacco, and apply another 20% 45 days after transplanting flue-cured tobacco.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com