Hair bleaching agent and preparation process thereof

A preparation process and technology of bleaching agent, applied in the field of hair bleaching agent and its preparation, can solve problems such as dust, inconvenient stirring or use process, poor conditioning of one agent, etc., and achieve the effect of prolonging the storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

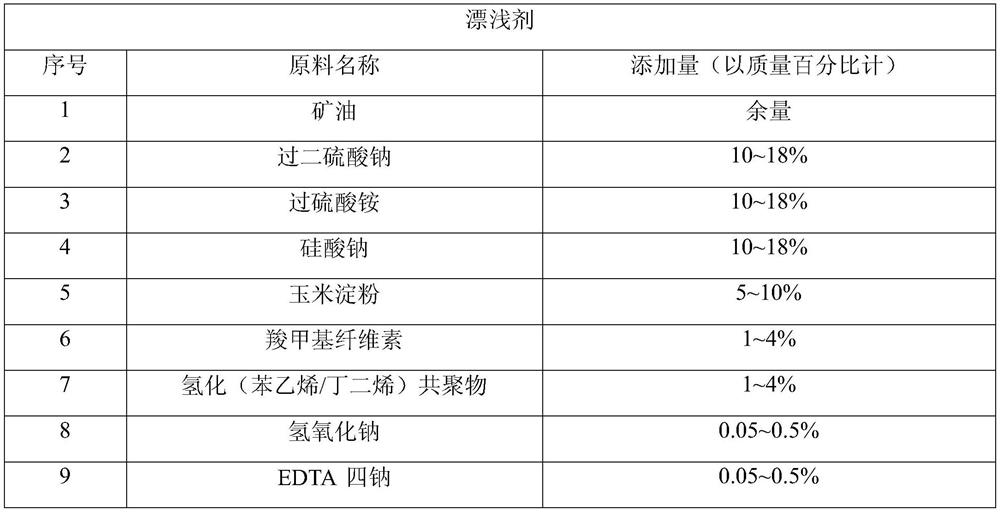

Embodiment 1

[0042]

[0043]

[0044] The preparation method of bleaching agent described in embodiment 1:

[0045] S1. Heat up, add mineral oil and hydrogenated (styrene / butadiene) copolymer into the pot, stir until uniform, and start cooling;

[0046] S2. Add sodium peroxodisulfate and ammonium persulfate to the mixture prepared in S1 and stir;

[0047]S3. Add carboxymethyl cellulose, cornstarch, sodium hydroxide, sodium silicate and tetrasodium EDTA to the mixture prepared in S2 and stir evenly, then discharge;

[0048] S4. After the material is discharged in S3, the semi-finished products pass the inspection, canned, packaged, and put into storage after passing the inspection.

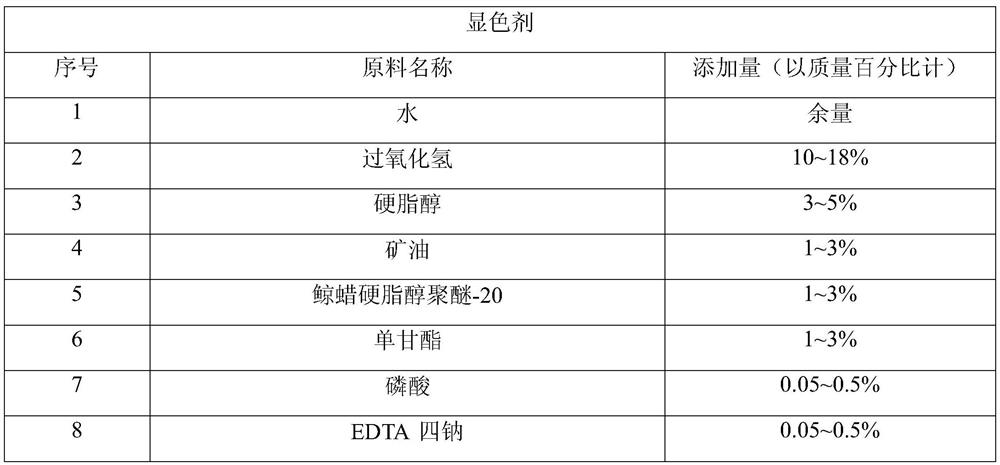

[0049] The preparation method of developer described in embodiment 1:

[0050] S01. Add water and tetrasodium EDTA into the emulsification pot, heat and stir evenly;

[0051] S02. Add stearyl alcohol, monoglyceride, mineral oil, ceteareth-20 into the oil phase pot, heat and stir evenly;

[0052] S03. ...

Embodiment 2

[0057]

[0058]

[0059]

[0060] The preparation method of bleaching agent described in embodiment 2:

[0061] S1. Heat up, add mineral oil and hydrogenated (styrene / butadiene) copolymer into the pot, stir until uniform, and start cooling;

[0062] S2. Add potassium peroxodisulfate and ammonium persulfate to the mixture prepared in S1 and stir;

[0063] S3. Add hydroxypropyl cellulose, corn starch, sodium metasilicate and tetrasodium EDTA to the mixture prepared in S2 and stir evenly;

[0064] S4..Add polyquaternium-10 to the mixture prepared in S3, stir evenly, cool, and then discharge;

[0065] S5. After the material is discharged in S4, the semi-finished product passes the inspection, canned, packaged, and put into storage after passing the inspection.

[0066] The preparation method of developer described in embodiment 2:

[0067] S01. Add water and tetrasodium EDTA into the emulsification pot, heat and stir evenly;

[0068] S02. Add stearyl alcohol, monoglyc...

Embodiment 3

[0074]

[0075]

[0076] The preparation method of described bleaching agent:

[0077] S1. Heat up, add mineral oil and hydrogenated (styrene / butadiene) copolymer into the pot, stir until uniform, and start cooling;

[0078] S2. Add potassium peroxodisulfate and ammonium persulfate to the mixture prepared in S1 and stir;

[0079] S3. Add hydroxyethyl cellulose, cornstarch, sodium metasilicate and disodium EDTA to the mixture prepared in S2 and stir evenly;

[0080] S4..Add polyquaternium-10 to the mixture prepared in S3, stir evenly, cool, and then discharge;

[0081] S5. After the material is discharged in S4, the semi-finished product passes the inspection, canned, packaged, and put into storage after passing the inspection.

[0082] The preparation method of described developer:

[0083] S01. Add water and disodium EDTA into the emulsification pot, heat and stir evenly;

[0084] S02. Add stearyl alcohol, monoglyceride, mineral oil, ceteareth-25 into the oil phase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com