Milling cutter cleaning device

A cleaning device and milling cutter technology, applied in electrode cleaning, maintenance and safety accessories, external electrostatic separators, etc., can solve the problem of waste chip adhesion, etc., to increase the adhesion area, strengthen the absorption effect, and increase the number of effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

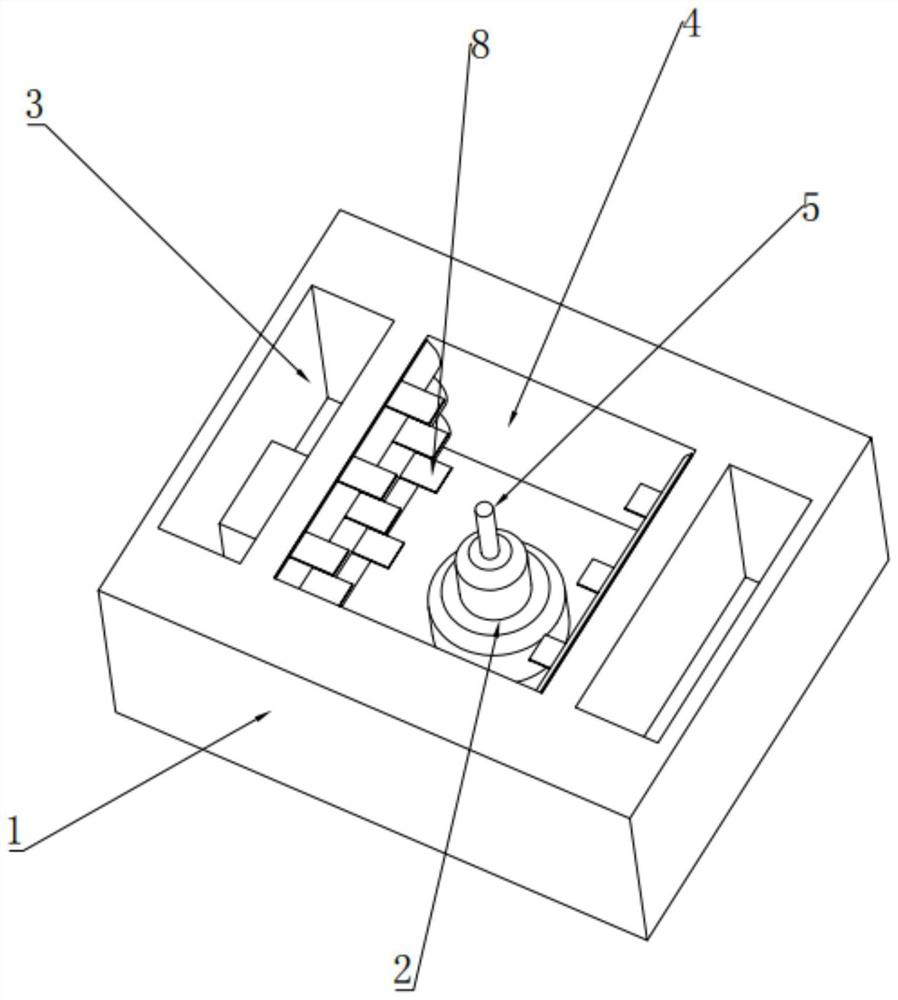

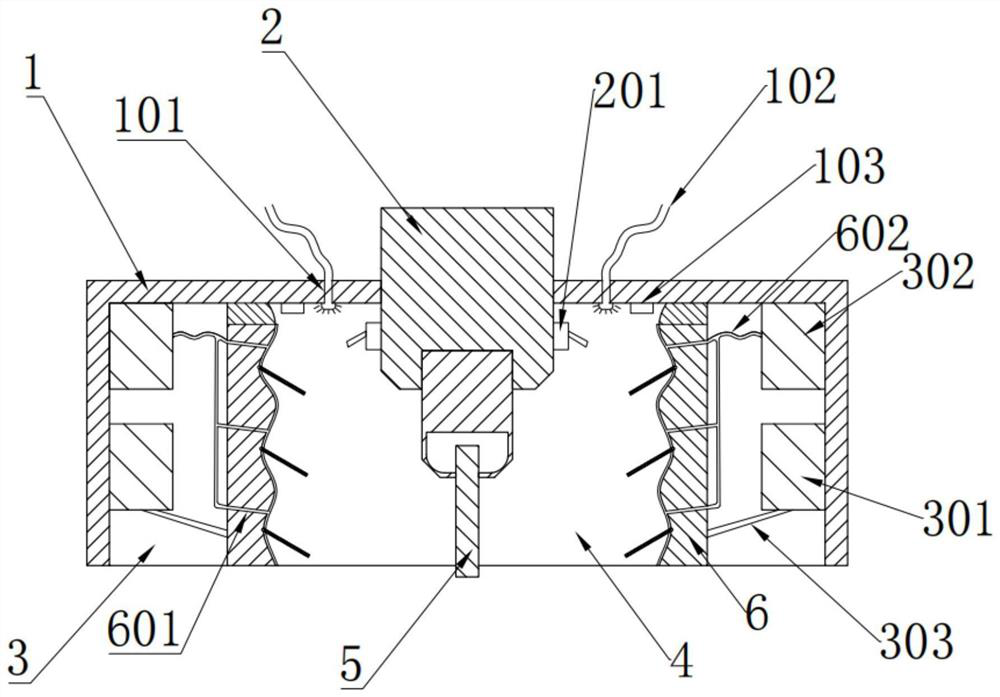

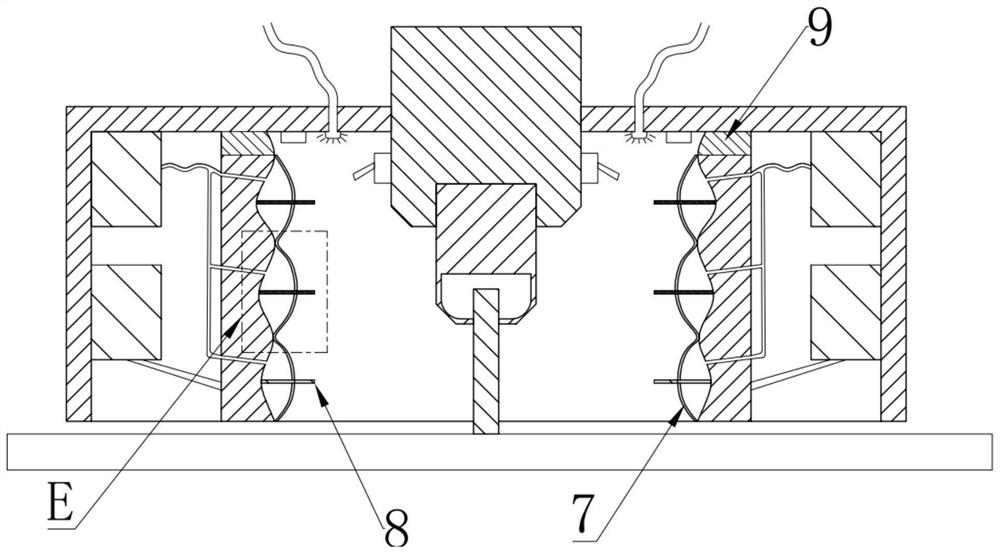

[0020] A milling cutter cleaning device, which includes a housing 1, which can be fixed on a milling machine spindle mechanism 2, the housing 1 is provided with a working chamber 3 and a cleaning chamber 4, and the working chamber 3 is located in the On both sides of the housing 1, the cleaning cavity 4 has a spindle mechanism 2 of the milling machine, and the milling cutter 5 is fixed to the spindle mechanism 2 for work. The spindle mechanism 2 is provided with a laser transmitter 201. The cleaning cavity 4 An electrostatic wall 6 is arranged between the working chamber 3, and an electrostatic generator 301 and an air pump 302 are arranged in the working chamber 3. The electrostatic generator 301 is connected to the electrostatic wall 6 through an electrostatic rod 303, and the electrostatic wall 6 There is a ventilation hole 601 on the upper part, and the air pump 302 communicates with the ventilation hole 601 through the air pipe 602. The upper end of the housing 1 is evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com