4D printing method for controlling deformation of liquid crystal elastomer material

A liquid crystal elastomer and material deformation technology, applied in the direction of additive manufacturing, manufacturing tools, additive processing, etc., can solve the problems of limiting the deformation flexibility of intelligent drives, and achieve the effect of multi-stage reversible shape change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The experimental materials were prepared by the addition method, and the liquid crystal monomer C6m (RM82), n-butylamine and photoinitiator were mixed with a mass ratio of 1:1:0.01. Seal the reaction flask with a bottle stopper with a stirring hole, put the flask into an oil bath at a temperature of 100° C., and then use a stirring device to stir the mixture at a speed of 80 / min for 18 hours. After the reaction, the liquid crystal ink was placed in a refrigerator at -5°C for ice bath quenching for 2 hours, and then the material was placed into an extrusion printing syringe for direct-write photocuring printing.

Embodiment 2

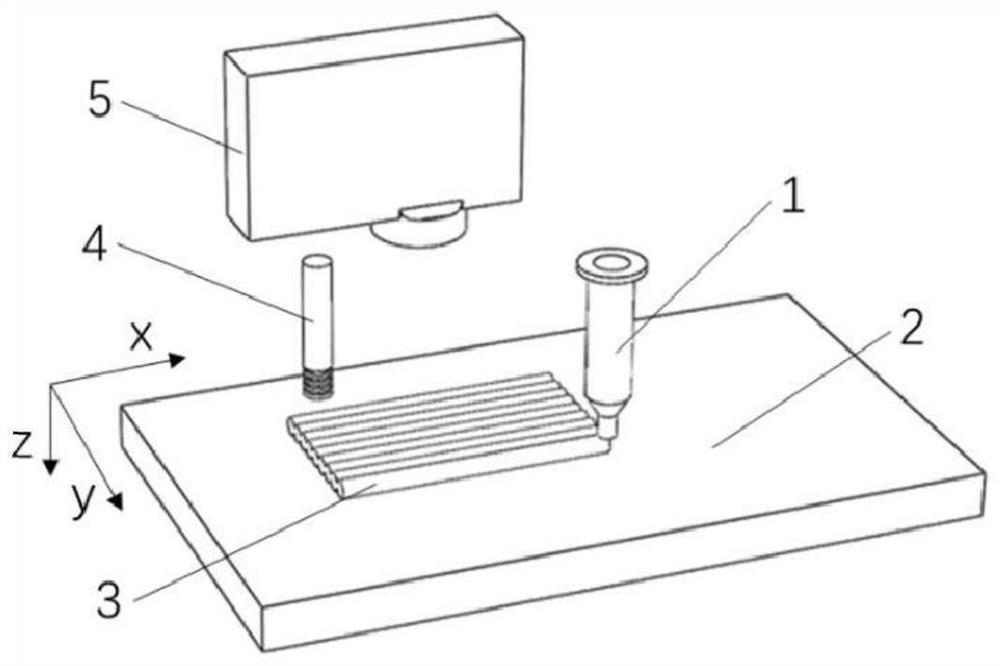

[0035] Use customized direct-write extrusion head printers for material build-up molding printing, printing devices such as figure 1 As shown, 1 is the direct writing extrusion head, and the material is placed in the extrusion head and extruded by air pressure. 2 is the material forming substrate, which can be driven by the sliding table below to move along the XYZ axis. 3 is the liquid crystal elastomer precursor material extruded on the molding substrate. 4 is the ultraviolet light curing head, which can emit 365nm ultraviolet light head to cure the printed sample. Since the photoinitiator IRGACURE 369 is added to the precursor material, it can cause further curing of the liquid crystal elastomer material under the irradiation of ultraviolet light. Polymerization fixes the orientation of the liquid crystal.

[0036] The distance between the UV curing head and the direct writing printing extrusion head is 50mm, and the super-condensing lens is selected as the lens of the UV...

Embodiment 3

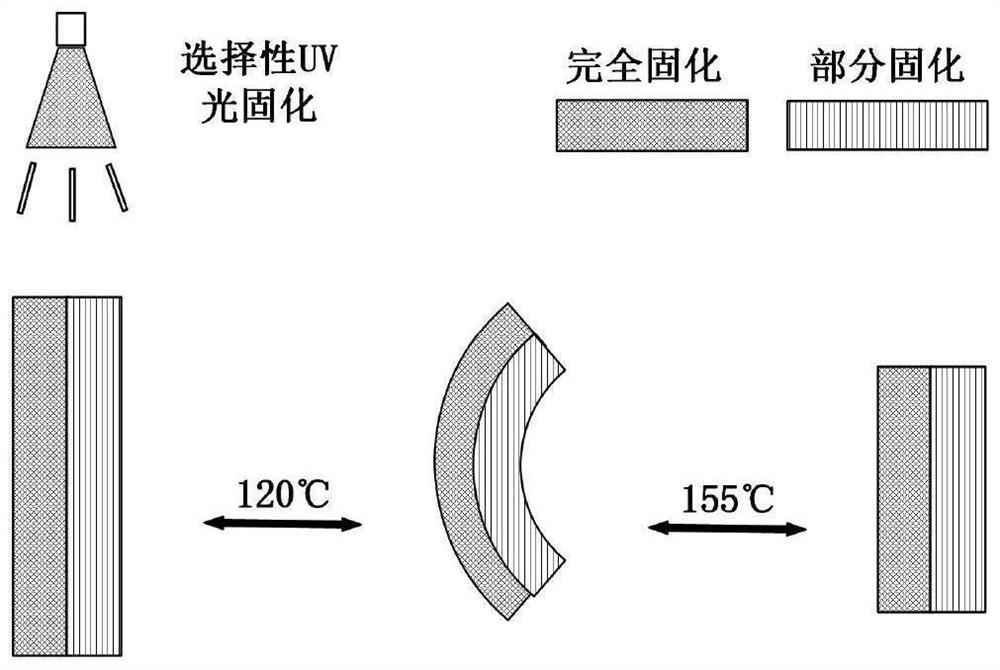

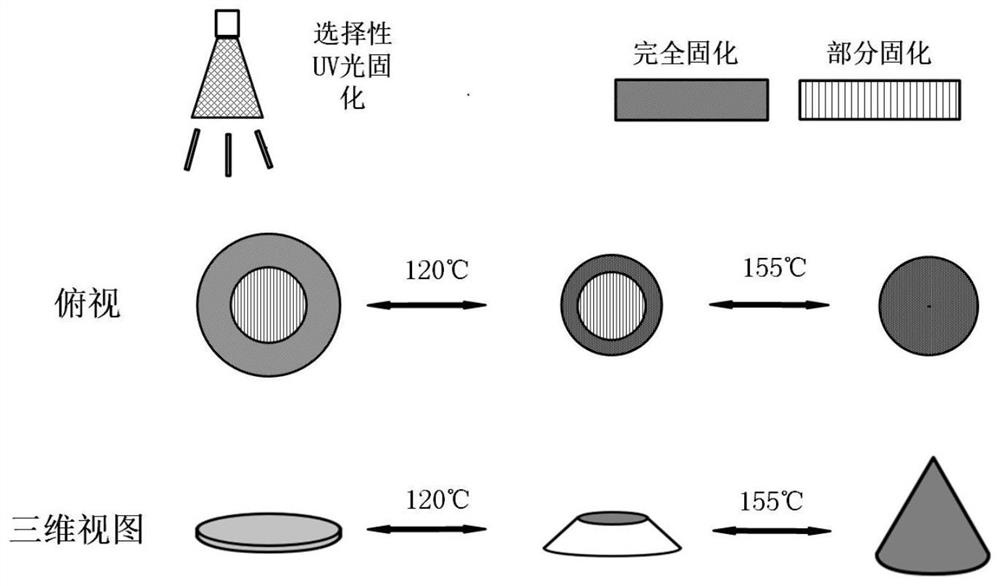

[0043] Such as figure 2 A difference in crosslink density is introduced on both sides of a rectangular spline as shown, the left side is a region of high crosslink density fully cured using a high UV light meter with a total irradiance meter of 200mw / cm 2 , on the right is a lightly cross-linked area cured with low UV light metering, with a total irradiance metering of 50mw / cm 2 . At a low stimulation temperature of 120 °C, the low crosslink density region first undergoes phase transition shrinkage, causing length differences along the long sides, and the component bends in-plane toward the low crosslink density region, transforming from a rectangle to a semicircle. When the temperature continues to rise to the high stimulation temperature of 155°C, the fully cured high-crosslinking density region also undergoes phase transition shrinkage, and the semicircular sample continues to deform into a rectangular spline. Further, when the temperature continues to decrease, the recta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com