Synthesis method of 1-fluoronaphthalene

A synthetic method and technology of fluoronaphthalene, applied in the field of synthesis of 1-fluoronaphthalene, capable of solving the problems of low yield of 1-fluoronaphthalene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

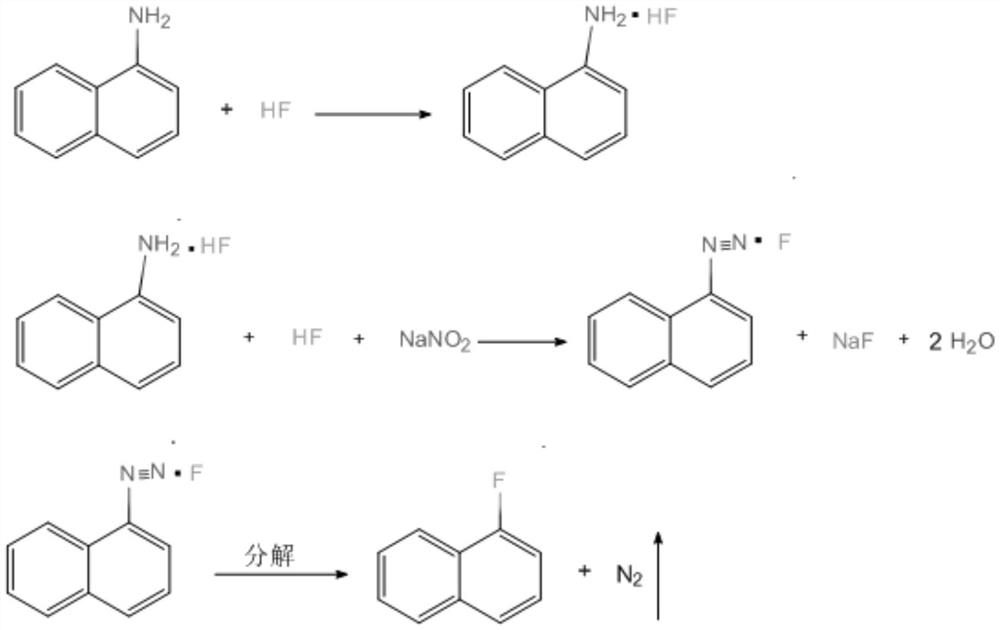

[0019] This specific embodiment provides a kind of synthetic method of 1-fluoronaphthalene, comprises the following steps:

[0020] S1, adding menaphthylamine to anhydrous hydrofluoric acid below 10°C to form menaphthylamine hydrofluoride; the mass ratio of said anhydrous hydrofluoric acid to said menaphthylamine is (2-5):1 ;

[0021] S2. Add anhydrous nitrite to the menaphthylamine hydrofluoride, and perform a diazotization reaction below 5°C to obtain an α-diazonaphthyl hydrofluoride solution; the anhydrous nitrate and the The mass ratio of menaphthylamine hydrofluoride is 1:(1.8-2); Further, described anhydrous nitrite is anhydrous sodium nitrite or anhydrous potassium nitrite;

[0022] S3. Thermally decomposing the α-diazonaphthalene hydrofluoride solution in a thermal decomposer at 50-80° C. to obtain a solution containing 1-fluoronaphthalene;

[0023] S4. Layering the solution containing 1-fluoronaphthalene to obtain a lower organic layer and an upper acid layer, neutr...

Embodiment 1

[0028] The present embodiment proposes a kind of synthetic method of 1-fluoronaphthalene, comprises the following steps:

[0029] S1, adding menaphthylamine to anhydrous hydrofluoric acid at 5°C to form menaphthylamine hydrofluoride; the mass ratio of said anhydrous hydrofluoric acid to said menaphthylamine is 3:1; menaphthylamine It is a block solid below 50°C, so menaphthylamine needs to be crushed into powder and then fed with an auger;

[0030] S2. Add anhydrous sodium nitrite to the menaphthylamine hydrofluoride, and perform a diazotization reaction at 5° C. to obtain an α-diazonaphthyl hydrofluoride solution; the anhydrous nitrate and the The mass ratio of menaphthylamine hydrofluoride is 1:1.8; Anhydrous nitrite is solid, therefore adopts auger to continuously and slowly wring in menaphthylamine hydrofluoride;

[0031] S3. Thermally decompose the α-diazonaphthalene hydrofluoride solution in a thermal decomposer at 50° C. to obtain a solution containing 1-fluoronaphthal...

Embodiment 2

[0034] The present embodiment proposes a kind of synthetic method of 1-fluoronaphthalene, comprises the following steps:

[0035] S1, adding menaphthylamine to anhydrous hydrofluoric acid at 8°C to form menaphthylamine hydrofluoride; the mass ratio of said anhydrous hydrofluoric acid to said menaphthylamine is 2:1; menaphthylamine It is a block solid below 50°C, so menaphthylamine needs to be crushed into powder and then fed with an auger;

[0036] S2. Add anhydrous sodium nitrite to the menaphthylamine hydrofluoride, and perform a diazotization reaction below 3°C to obtain an α-diazonaphthyl hydrofluoride solution; the anhydrous nitrate and the The mass ratio of menaphthylamine hydrofluoride is 1:2; Anhydrous nitrite is solid, so adopts auger to continuously slowly wring in menaphthylamine hydrofluoride;

[0037] S3. Thermally decompose the α-diazonaphthalene hydrofluoride solution in a thermal decomposer at 60°C to obtain a solution containing 1-fluoronaphthalene; at this t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com