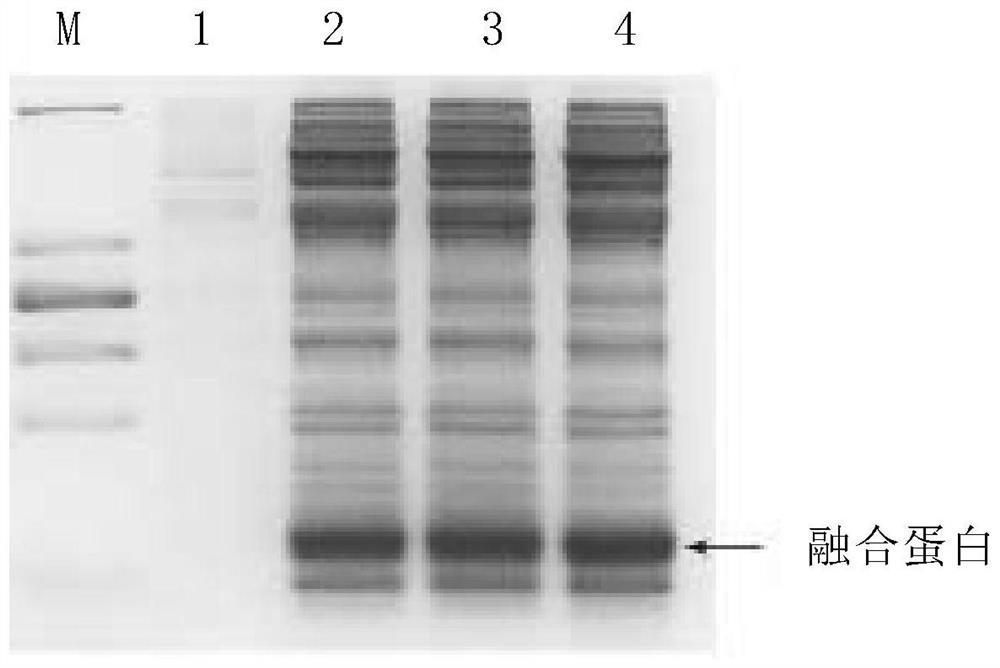

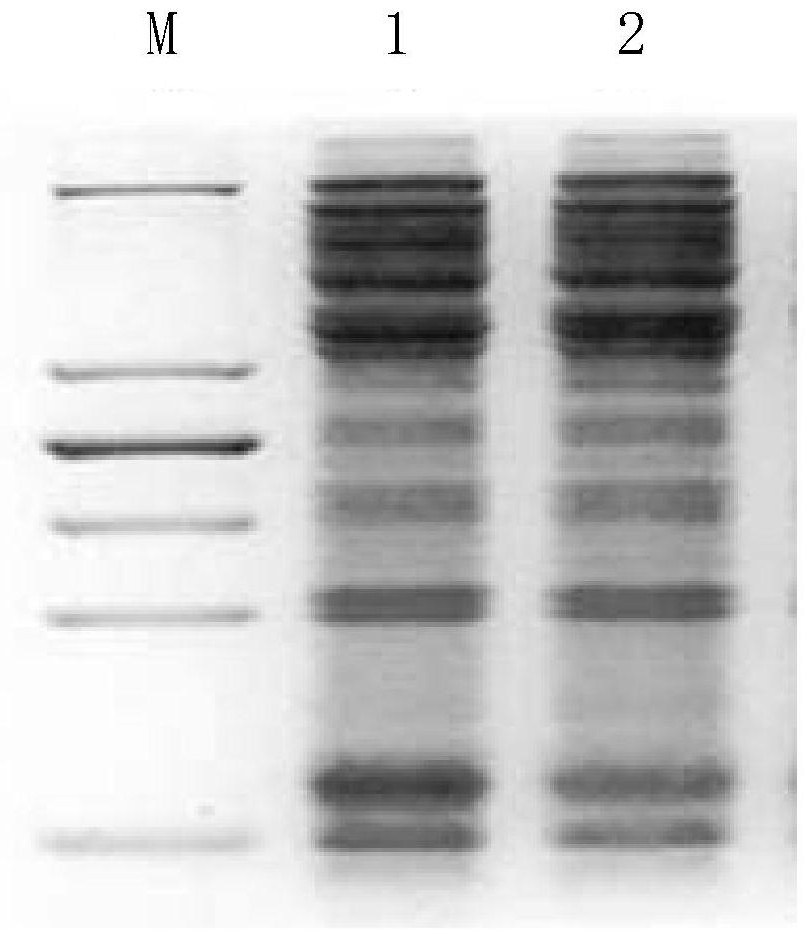

Fermentation culture method of recombinant escherichia coli for producing insulin aspart fusion protein

A technology for recombining Escherichia coli and insulin aspart, which is applied in the direction of insulin, microbial-based methods, fermentation, etc., can solve the problems of low expression, long induction culture time, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0087] Preparation of seed liquid: Inoculate the preserved recombinant Escherichia coli glycerol tube strain in a 500mL shake flask containing 100mL LB seed recovery medium, culture on a shaking table at 37±0.5°C, 220±20rpm for 8.5-10.5h, OD 600 After reaching 1.05-4.30, it is used as seed resuscitation solution; connect 1mL seed resuscitation solution to a 500mL shake flask containing 100mL seed adaptive growth medium, culture at 37±0.5°C, 220±20rpm shaker for 5.5-6.5h, OD 600 Reach 2.5-10.5 as seed liquid for fermentation.

[0088] Batch culture: 0.1L seed liquid was put into a 5L fermenter containing 2.0L fermentation medium, the initial culture conditions were 33°C, pH 7.0, rotation speed 200rpm, ventilation rate 1vvm, tank pressure 0.03mPa. As the cultivation progresses, increase the rotational speed and air flow accordingly, so that the dissolved oxygen is controlled at 5-40%, and cultivate for 4-5 hours. After the dissolved oxygen and pH rise rapidly, enter the fed-batc...

Embodiment 1

[0100]Preparation of seed liquid: Inoculate the preserved recombinant Escherichia coli glycerol tube strain in a 500mL shake flask containing 100mL LB seed recovery medium, culture on a shaking table at 37±0.5°C, 220±20rpm for 8.5-10.5h, OD 600 After reaching 1.05-4.30, it is used as seed resuscitation solution; connect 1mL seed resuscitation solution to a 500mL shake flask containing 100mL seed adaptive growth medium, culture at 37±0.5°C, 220±20rpm shaker for 5.5-6.5h, OD 600 Reach 2.5-10.5 as seed liquid for fermentation;

[0101] Batch culture: 0.1L seed liquid was put into a 5L fermenter containing 2.0L fermentation medium, the initial culture conditions were 33°C, pH 7.0, rotation speed 200rpm, ventilation rate 1vvm, tank pressure 0.03mPa. As the cultivation progresses, increase the rotation speed and air flow accordingly, so that the dissolved oxygen is controlled at 5-40%, and cultivate for 4-5 hours. After the dissolved oxygen and pH rise rapidly, enter the feeding fer...

Embodiment 2

[0108] Preparation of seed liquid: Inoculate the preserved recombinant Escherichia coli glycerol tube strain in a 500mL shake flask containing 100mL LB seed recovery medium, culture on a shaking table at 37±0.5°C, 220±20rpm for 8.5-10.5h, OD 600 After reaching 1.05-4.30, it is used as seed resuscitation solution; connect 1mL seed resuscitation solution to a 500mL shake flask containing 100mL seed adaptive growth medium, culture at 37±0.5°C, 220±20rpm shaker for 5.5-6.5h, OD 600 Reach 2.5-10.5 as seed liquid for fermentation;

[0109] Batch culture: 0.1L seed liquid was put into a 5L fermenter containing 2.0L fermentation medium, the initial culture conditions were 33°C, pH 7.0, rotation speed 200rpm, ventilation rate 1vvm, tank pressure 0.03mPa. As the cultivation progresses, increase the rotation speed and air flow accordingly, so that the dissolved oxygen is controlled at 5-40%, and cultivate for 4-5 hours. After the dissolved oxygen and pH rise rapidly, enter the feeding fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com