A high-entropy reinforced amorphous alloy composite material and its preparation method

A composite material and amorphous alloy technology, which is applied in the field of high entropy reinforced amorphous alloy composite material and its preparation, can solve problems such as the inability to completely solve the plasticity of amorphous alloys, and achieve constrained net shape, improve plasticity, and improve amorphous alloys. The effect of alloy brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

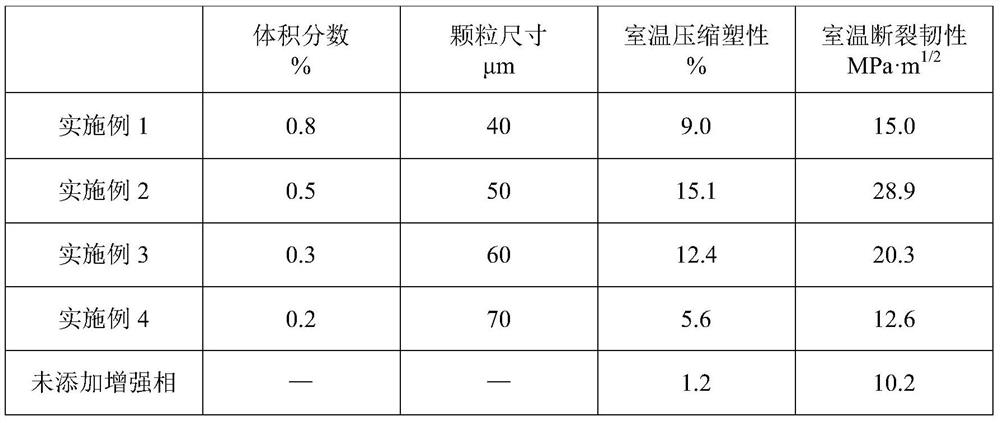

[0032] The volume fraction of the high-entropy reinforced phase in the composite material is 0.8%, and the size of the high-entropy alloy reinforced phase is 40 μm.

Embodiment 2

[0034] The volume fraction of the high-entropy reinforced phase in the composite material is 0.5%, and the size of the high-entropy alloy reinforced phase is 50 μm.

Embodiment 3

[0036] The volume fraction of the high-entropy reinforced phase in the composite material is 0.3%, and the size of the high-entropy alloy reinforced phase is 60 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com