A kind of fiber fabric self-lubricating composite material and its preparation method and application

A composite material, fiber fabric technology, applied in the direction of fiber processing, fiber type, textile and papermaking, etc., can solve the problem of not meeting the requirements of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

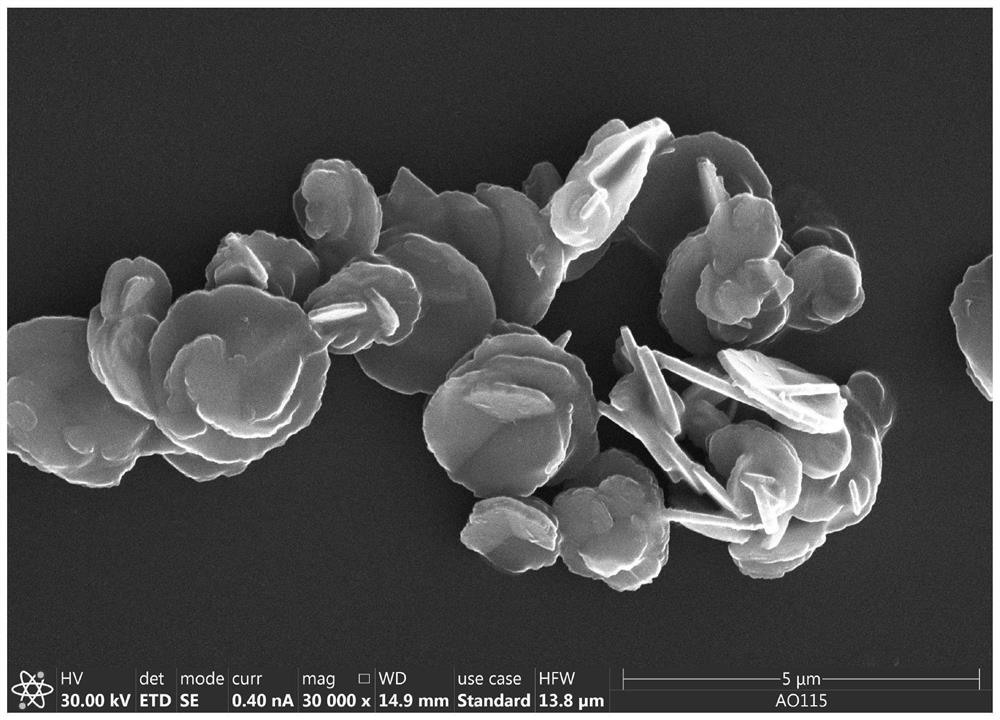

Image

Examples

preparation example Construction

[0025] The present invention provides the preparation method of the fiber fabric self-lubricating composite material described in the above scheme, comprising the following steps:

[0026] According to the mass ratio of polyetherimide and solid lubricant in the fiber fabric self-lubricating composite material, the polyetherimide and solid lubricant are dispersed in N,N-dimethylformamide to obtain an impregnating liquid;

[0027] The PEEK-PTFE blended fiber fabric is dipped into the dipping solution, and after drying, the fiber fabric self-lubricating composite material is obtained.

[0028] In the present invention, without special instructions, the raw materials used are all commercially available commodities well known in the art.

[0029] According to the mass ratio of the polyetherimide and the solid lubricant in the fiber fabric self-lubricating composite material, the polyetherimide and the solid lubricant are dispersed into N,N-dimethylformamide to obtain an impregnatin...

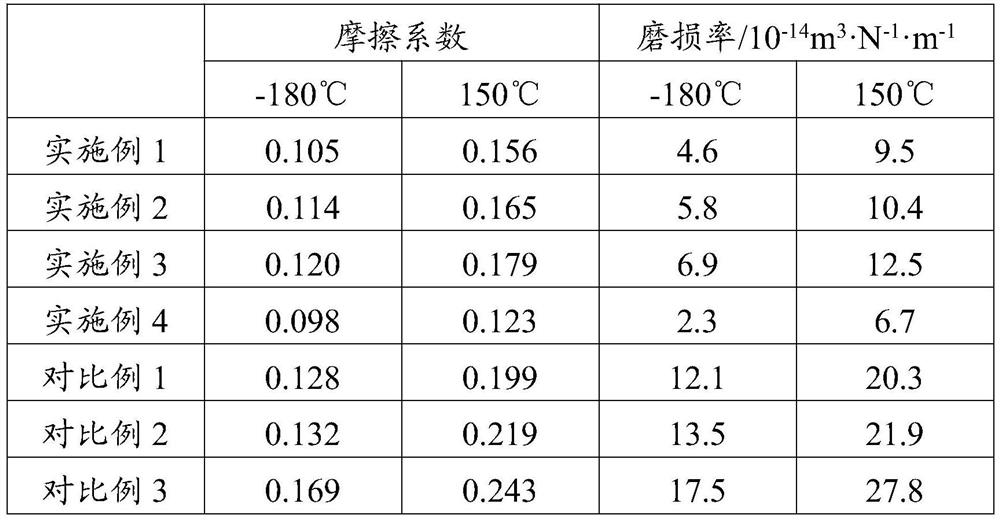

Embodiment 1

[0048] The PEEK-PTFE blended fiber fabric was placed in petroleum ether for ultrasonic cleaning for 35 minutes, dried and then placed in a mixed solution with an acetone:ethanol volume ratio of 3:2 for ultrasonic cleaning for 35 minutes, and dried at 80 °C for 2 hours after taking it out;

[0049] Put PEI, DMF, Ta 4 C 3 T x , V 4 C 3 T x Mix according to the mass ratio of 30:80:0.4:0.4, stir magnetically at a speed of 1500rpm for 3h, then put the pretreated fiber fabric into the impregnating solution, and dry it in a vacuum oven at 110°C. Repeated impregnation and drying The operation is carried out until the content of the fabric accounts for 60% of the total content of the composite material, and the fiber fabric self-lubricating composite material is obtained.

Embodiment 2

[0051] The PEEK-PTFE blended fiber fabric was placed in petroleum ether for ultrasonic cleaning for 30 min, dried and then placed in a mixed solution with an acetone:ethanol volume ratio of 3:1 for ultrasonic cleaning for 33 min, taken out and dried at 90 °C for 1.5 h;

[0052] Put PEI, DMF, Ta 4 C 3 T x , V 4 C 3 T x Mix according to the mass ratio of 20:77:0.3:0.3, stir magnetically at 1400rpm for 2.5h, then put the pretreated fiber fabric into the dipping solution, and dry it in a vacuum oven at 100 °C. Repeat the dipping and drying. Dry operation until the content of the fabric accounts for 70% of the total content of the composite material to obtain a fiber fabric self-lubricating composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com