Pt/VS2 catalytic material and preparation method and application thereof

A catalytic material and nanomaterial technology, applied in the field of nanomaterial preparation and hydrogen production catalyst, can solve the problems of cumbersome process, unfavorable large-scale promotion and application of electrolysis water hydrogen evolution technology, high temperature and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Example 1: VS 2 Preparation of nanosheets

[0071] 3mmol Na 3 VO 4 12H 2 O and 15mmol of thioacetamide were added to 40mL of deionized water, fully stirred until completely dissolved, and then transferred to a 50mL polytetrafluoroethylene reactor. Subsequently, a piece of carbon paper with a size of 1 cm×2 cm was immersed in the above solution, and then the reaction vessel was sealed and reacted at 160° C. for 24 h. After the reaction, the temperature was naturally lowered to room temperature, and then the carbon paper was taken out, washed with water and ethanol several times, and dried to obtain the VS grown on the carbon paper. 2 Nanosheets. Vacuum annealing at 300°C for 20 min to improve VS 2 Crystallinity of nanosheets.

Embodiment 2

[0072] Example 2: Pt / VS 2 Preparation of catalytic materials

[0073] will grow vs 2 The carbon paper of the nanosheets was respectively immersed in 10mL, 0.1mmol / L, 0.5mmol / L, 1mmol / L chloroplatinic acid solution, and placed in a 100mW cm -2 Irradiated under xenon light source for 0.5h. When the irradiation time is more than half, turn over the surface of the carbon paper to complete the reaction on the other side. After the reaction, the carbon paper was taken out, washed with water and ethanol several times, and dried to obtain the Pt single atom-VS 2 Nanosheet composite catalytic materials.

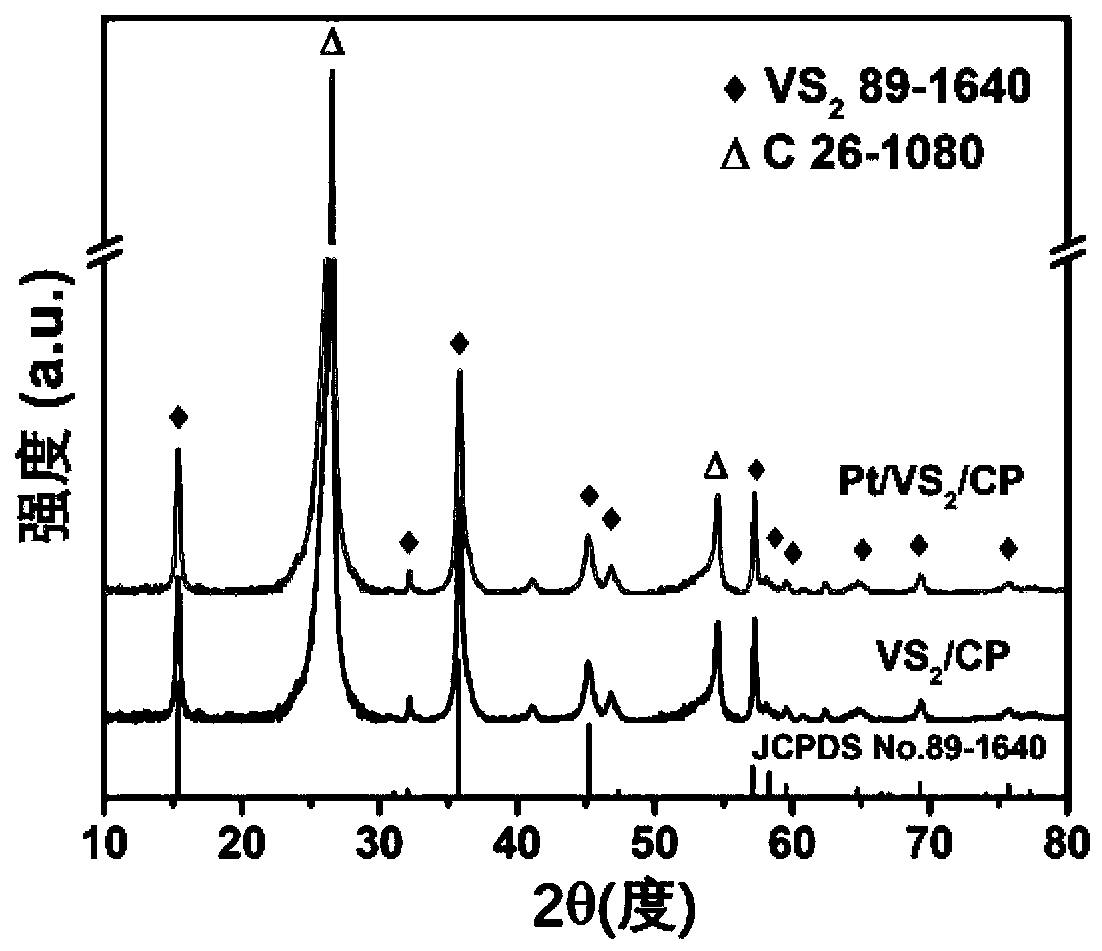

[0074] figure 1 for VS 2 Nanosheet (embodiment 1) and its X-ray diffraction pattern after trapping Pt atom (embodiment 2), proves that the introduction of Pt atom is to VS 2 The crystal structure of Pt has no effect, and the Pt atoms do not form particles, so there is no Pt diffraction peak.

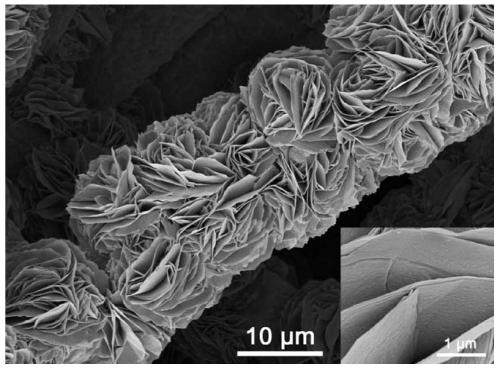

[0075] figure 2 For Pt / VS grown on carbon paper 2 The scanning electron micrograp...

Embodiment 3

[0077] Example 3: Pt / VS 2 Preparation of catalytic materials

[0078] will grow vs 2 The carbon paper of the nanosheets is immersed in 10mL, 0.1mmol / L, 0.5mmol / L, 1mmol / L chloroplatinic acid solution, placed in a 100mW cm -2 irradiated under a xenon light source for 1 h. When the irradiation time is more than half, turn over the surface of the carbon paper to complete the reaction on the other side. After the reaction, the carbon paper was taken out, washed with water and ethanol several times, and dried to obtain the Pt single atom / atom cluster-VS 2 Nanosheet composite catalytic materials.

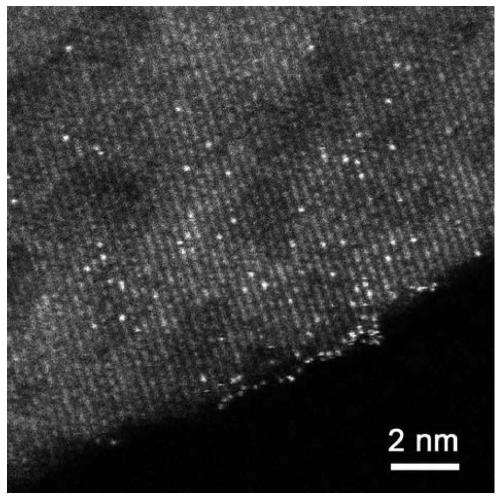

[0079] image 3 For the Pt single atom-VS prepared by 0.1mmol / L chloroplatinic acid solution in embodiment 2 2 Condenser spherical aberration electron microscope dark field image of nanosheet catalytic material, Figure 5 For the Pt single atom-VS prepared by 0.5mmol / L chloroplatinic acid solution in embodiment 2 2 Condenser spherical aberration electron microscope dark field imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com