An anti-corrosion shell structure and construction method for an offshore engineering platform

A technology of marine engineering and shell structure, applied in the field of marine engineering, can solve problems such as inconvenient use, troublesome construction process of anti-corrosion shell structure, lack of function of anti-corrosion shell structure, etc., and achieve the effect of avoiding blockage and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

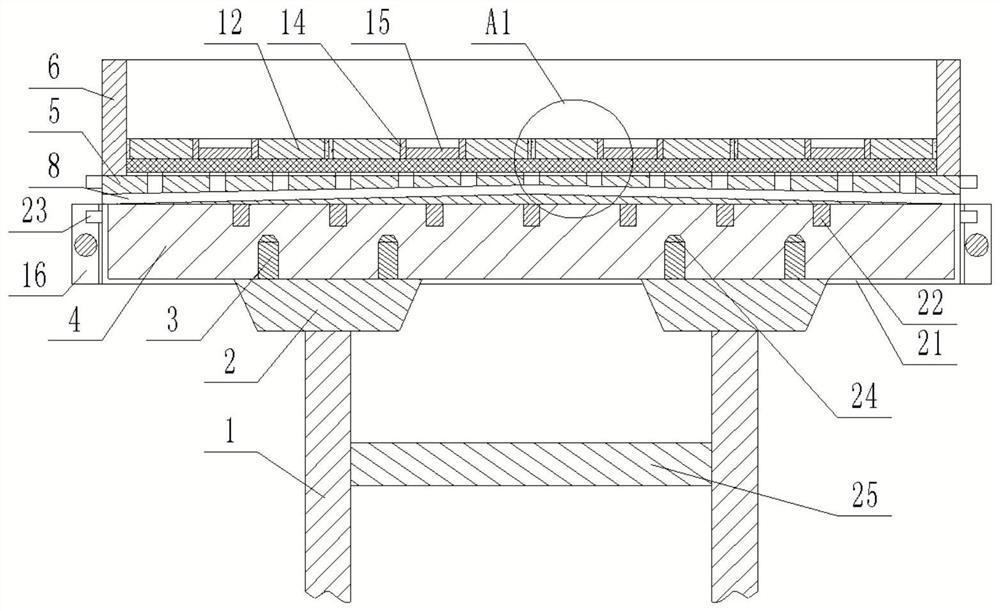

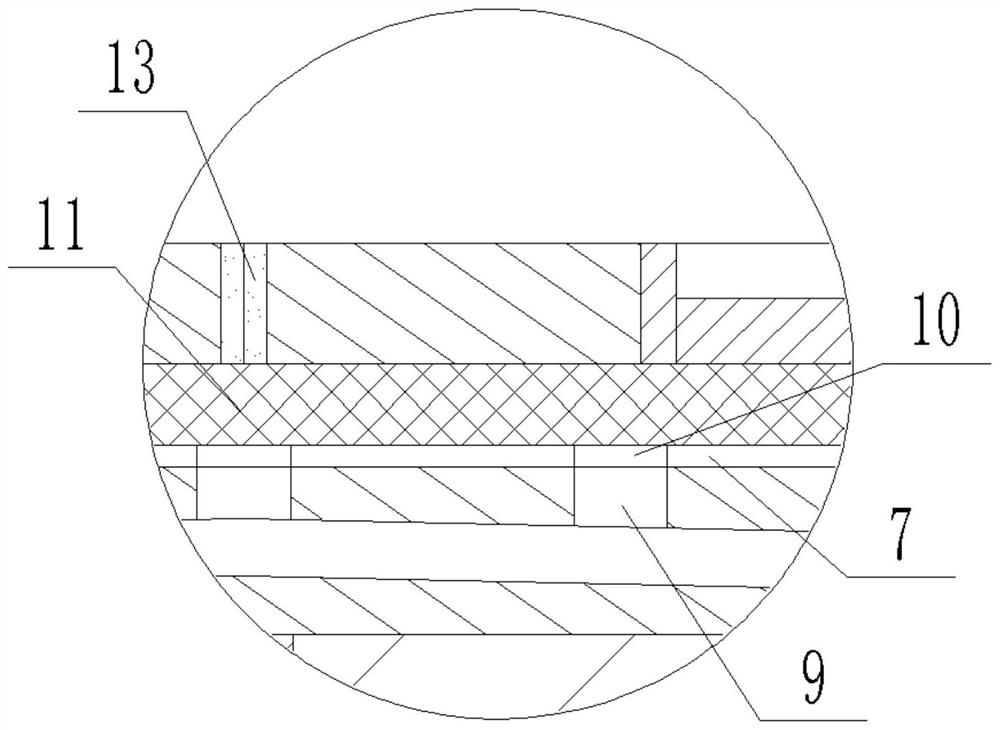

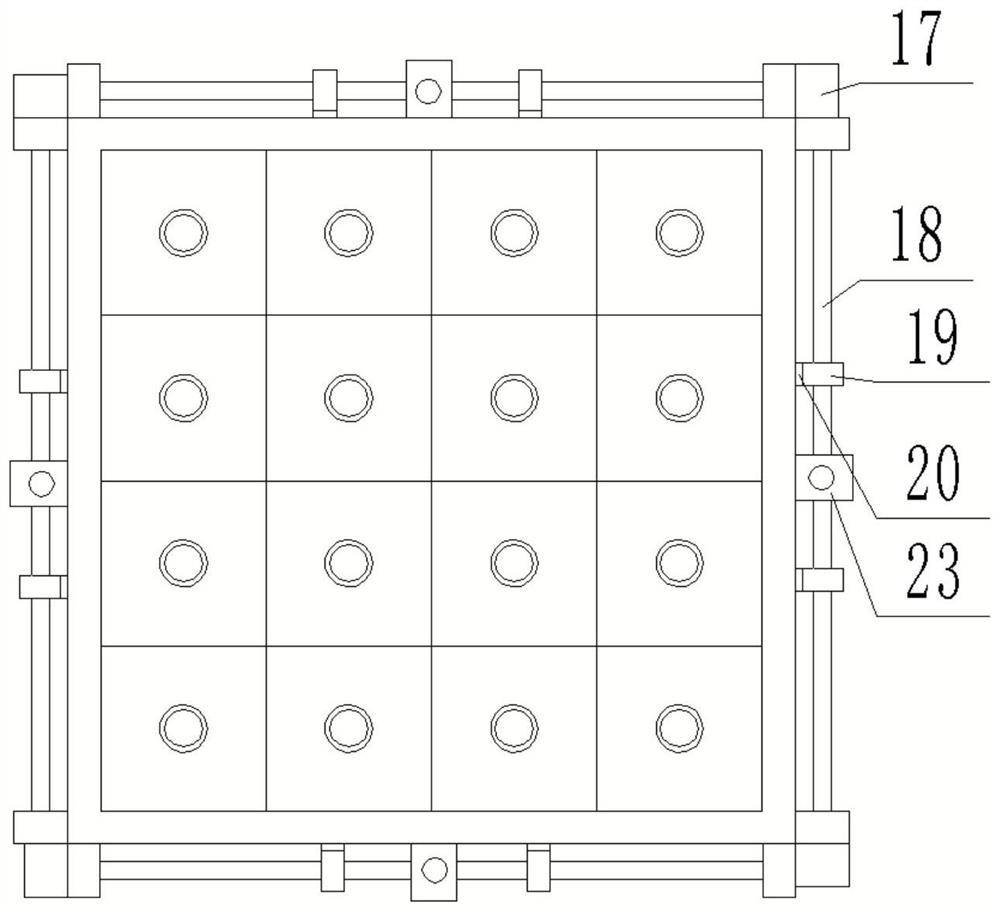

[0032] refer to Figure 1-3 , the present invention provides an anti-corrosion shell structure of an ocean engineering platform, comprising: four support columns 1 inserted into the seabed, a connection block 2 is fixedly connected to the top surface of the support column 1, and several connection columns are fixedly connected to the top surface of the connection block 2 3. The top surface of the connection block 2 is provided with a load-bearing plate 4, and the bottom surface of the load-bearing plate 4 is provided with a number of connecting grooves that match the connecting columns 3. The connecting columns 3 are plugged into the connecting grooves, and the top surface of the load-bearing plate 4 is provided with a protective plate 5 , the top surface of the protective plate 5 is fixedly connected with a protective cover 6, the protective cover 6 is provided with a filter device, the bottom surface of the filter device is fixedly connected with a water-proof layer 7, the bo...

Embodiment 2

[0055] refer to Figure 4 , because the support column 1 of the offshore platform has no protective device, it is easily corroded by seawater, and its service life is very short. Therefore, in this embodiment, a heating film 26 is arranged on the outer wall of the support column 1. The heating film 26 provided is the prior art, so it is not enough For more details, the heating film 26 is fixed to the inner concrete layer 27, and the inner concrete layer 27 is embedded with a conductive coil 28. The conductive coil 28 is electrically connected to the heating film 26, and the conductive coil 28 is externally connected to a power supply. The outer wall is fixed with an insulating layer 30, and an anti-corrosion shell 31 is arranged outside the insulating layer 30, and the heating film 26 is powered through the conductive coil 28, and finally the heating film 26 is heated to generate heat, which generates heat around the support column 1, preventing the support column 1 from contac...

Embodiment 3

[0057] refer to Figure 5 , in order to reduce the self-weight of the support column 1 as a whole, enhance plasticity, improve the seismic performance of the structure, and facilitate construction, the support column 1 in this embodiment is made of steel column material, and the outer concrete layer 32 is poured on the outside of the support column 1. At the same time, steel bars 29 are spirally embedded in the outer concrete layer 32 to increase the bearing capacity, durability and safety of the support column 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com