Optical system

A technology of optical system and optical path, which is applied in the field of optical system, can solve the problem of low efficiency of laser direct writing and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

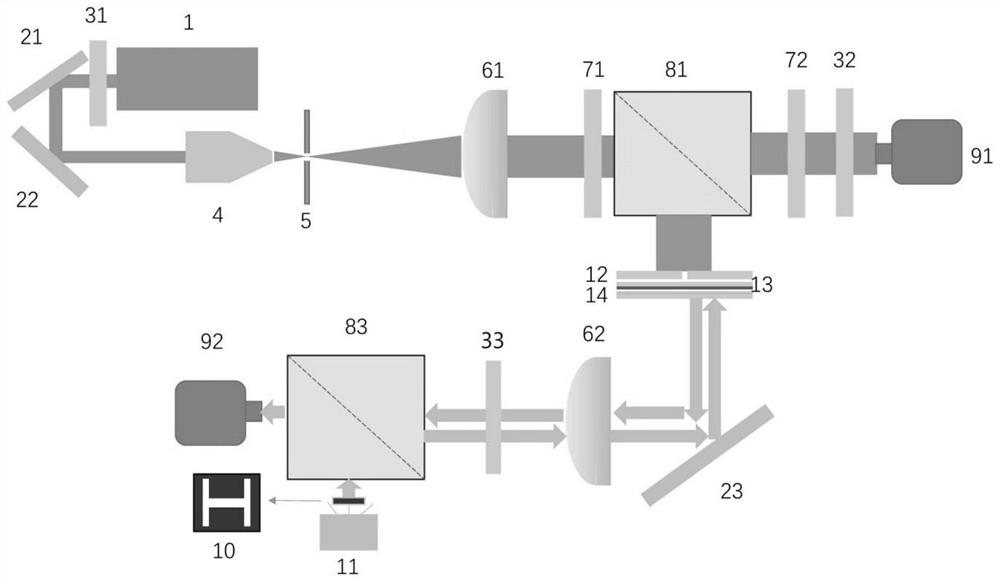

[0032] This embodiment discloses an optical system, including:

[0033] Exposure light path and alignment light path.

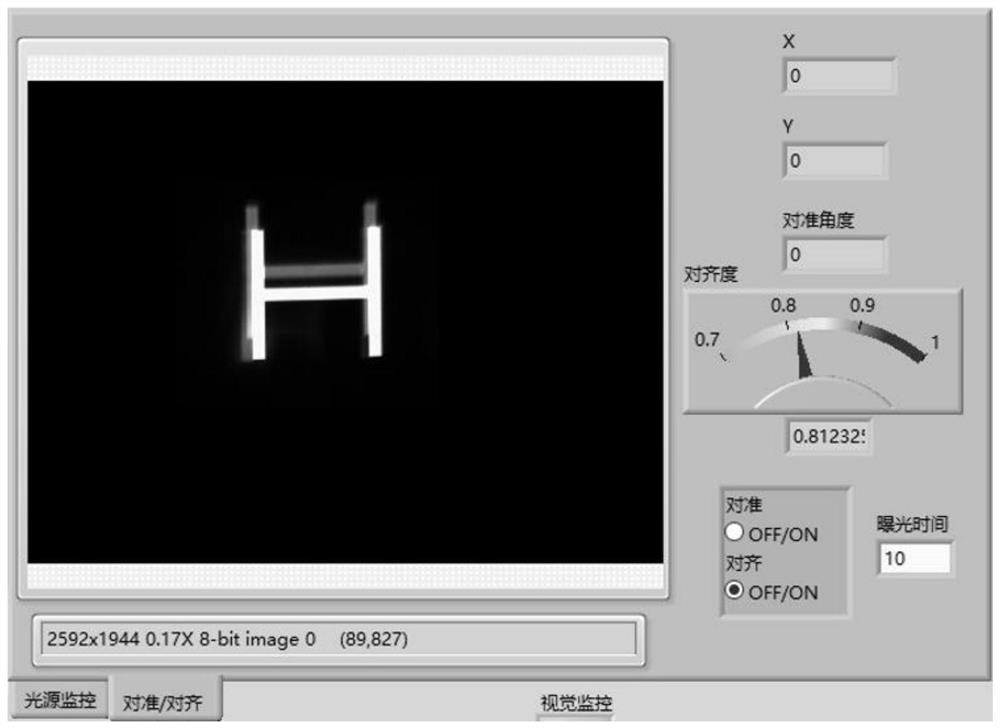

[0034] On the exposure optical path, a mask plate, a template and a sample substrate are sequentially arranged; the sample substrate is provided with a photosensitive material for converting or duplicating the polarization information of the template through exposure and placed on a displacement stage; The mask plate and the template are in a parallel relationship perpendicular to the light path. In this embodiment, the so-called "polarization information conversion or replication" refers to the conversion or replication of the polarization information of the template, which is related to the template and the incident light; the template usually uses a half-wave or 1 / 4-wave geometric phase device to meet the specific requirements of the incident light After passing through the template, diffraction will occur. When the diffracted lights of different orders o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com