Space engine jet pipe and spacecraft

An engine nozzle and space technology, which is used in instruments, computer-aided design, special data processing applications, etc., can solve the problem of not having infrared stealth function, etc., and achieve the effect of reducing infrared emissivity and improving infrared stealth ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

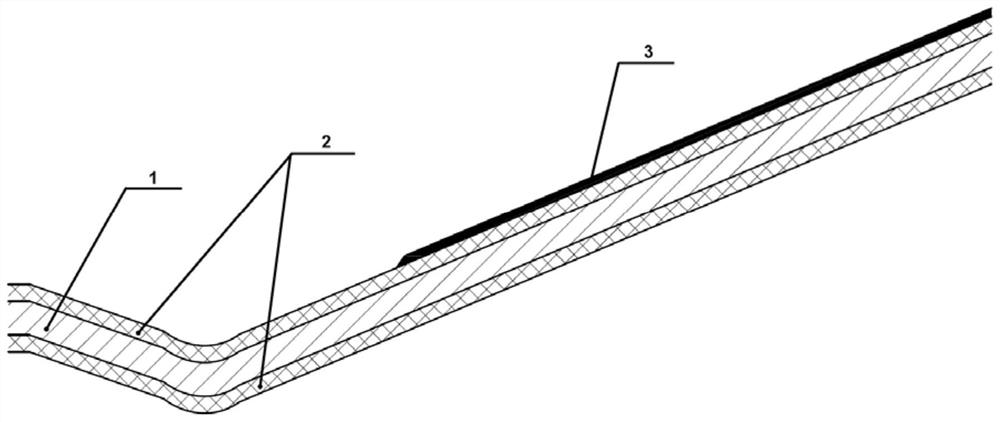

[0028] Such as figure 1 As shown, a space engine nozzle provided according to the present invention includes a niobium alloy substrate 1, an oxidation-resistant silicide coating 2 and an infrared stealth coating 3; A thin-walled rotary body in the shape of a nozzle, the left contracting end of the nozzle shrinks from large to small toward the middle throat, and the middle throat expands from small to large toward the right expanding end.

[0029] The anti-oxidation silicide coating 2 is sprayed on the inner surface and the outer surface of the niobium alloy substrate 1; the preparation area of the infrared stealth coating 3 is located on the outer wall of the expansion end of the engine nozzle, and the infrared stealth coating 3 includes a matching layer, a bonding layer and The low-emissivity layer; the matching layer is prepared on the anti-oxidation silicide coating 2 on the outer surface of the niobium alloy substrate 1, the adhesive layer is prepared on the matching lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Total length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap