Transverse time-of-flight cluster mass selector and use method thereof

A technology of mass selection and time grouping, which is applied in the fields of atomic and molecular physics and nanoscience, can solve the problems of limited mass selection range of quadrupole mass filter, high quality requirements of cluster beams, and reduced quality of cluster beams, etc. Intuitive and simple to achieve debugging and operation, conducive to beam quality, and constant mass resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

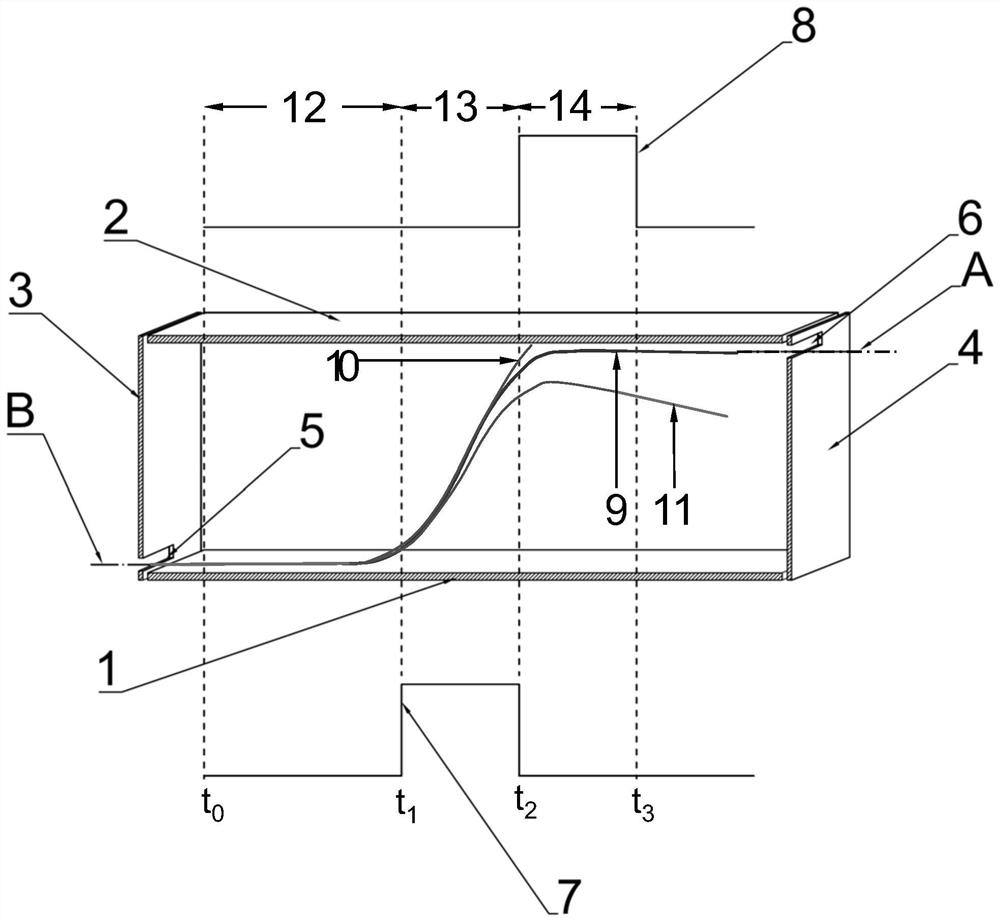

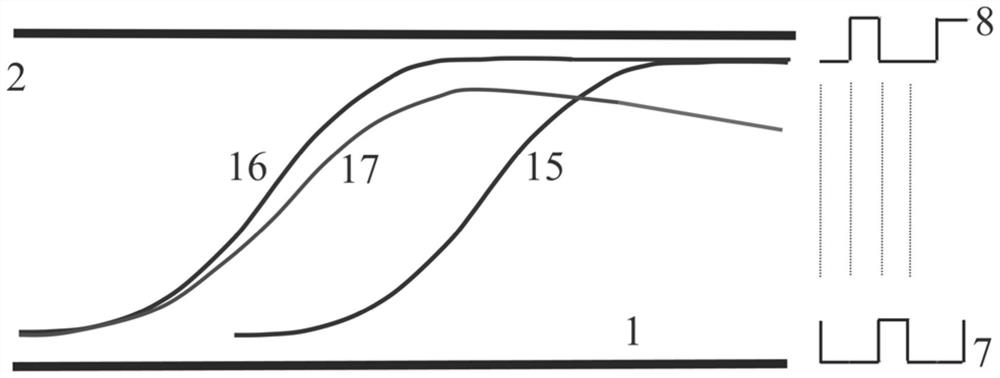

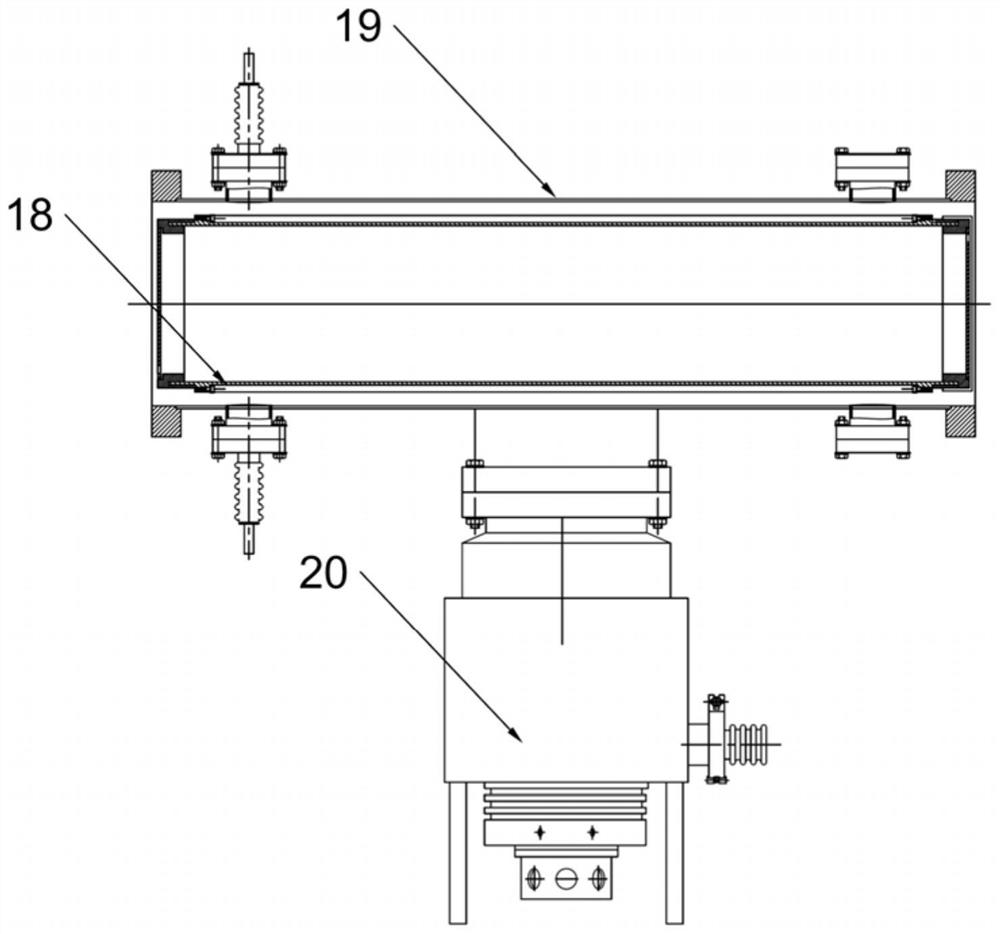

[0030] like figure 1 and 3 As shown, a transverse time-of-flight cluster mass selector, the mass selector includes parallel plate electrodes 1 and 2 parallel to each other, an entrance slit plate 3 and an exit slit plate 4 arranged in parallel, the parallel plate electrodes and The slit plates are vertical and fit together, and the mass selector is installed in the vacuum chamber 19 . The materials of the parallel plate electrode, the entrance slit plate 3 and the exit slit plate 4 are all aluminum; the parallel plate electrode is a rectangular plate with a length of 740 mm, a width of 100 mm, and a thickness of 3 mm; two parallel plate electrodes are placed in parallel, and the inside of the plate is The distance between the surfaces is 150 mm, and electrical insulation is maintained between the plates; the entrance slit plate 3 and the exit slit plate 4 are placed at both ends of the long side of the parallel plate, perpendicular to the electrode plane of the parallel plate...

Embodiment 2

[0037] like figure 1 and 3As shown, a transverse time-of-flight cluster mass selector, the mass selector includes parallel plate electrodes 1 and 2 parallel to each other, an entrance slit plate 3 and an exit slit plate 4 arranged in parallel, the parallel plate electrodes and The slit plate is vertical and fitted, and the mass selector is installed in the vacuum chamber. The materials of the parallel plate electrode, the entrance slit plate 3 and the exit slit plate 4 are all stainless steel; the parallel plate electrode is a rectangular plate with a length of 600 mm, a width of 120 mm, and a thickness of 2 mm; two parallel plate electrodes are placed in parallel, and the inside of the plate is The distance between the surfaces is 200 mm, and electrical insulation is maintained between the plates; the entrance slit plate 3 and the exit slit plate 4 are placed at both ends of the long side of the parallel plate, perpendicular to the electrode plane of the parallel plate, and ...

Embodiment 3

[0044] like figure 1 and 3 As shown, a transverse time-of-flight cluster mass selector, the mass selector includes parallel plate electrodes 1 and 2 parallel to each other, an entrance slit plate 3 and an exit slit plate 4 arranged in parallel, the parallel plate electrodes and The slit plates are vertical and fit together, and the mass selector is installed in the vacuum chamber 19 . The materials of the parallel plate electrode, the entrance slit plate 3 and the exit slit plate 4 are all aluminum; the parallel plate electrode is a rectangular plate with a length of 250 mm, a width of 40 mm, and a thickness of 2 mm; two parallel plate electrodes are placed in parallel, and the inside of the plate is The distance between the surfaces is 50 mm, and electrical insulation is maintained between the plates; the entrance slit plate 3 and the exit slit plate 4 are placed at the two ends of the long side of the parallel plate, perpendicular to the electrode plane of the parallel plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com