Display panel and preparation method thereof

A technology for display panels and array substrates, applied in electrical components, electrical solid-state devices, circuits, etc., can solve the problems of blue-light Micro-LEDs with different luminous efficiency, performance and lifespan, difficulty in achieving full color, and low yield. The effect of reducing the probability of non-radiative relaxation, improving luminous efficiency and high color purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] According to the display panel of the above-mentioned embodiment, the present invention also provides a method for preparing the display panel, the preparation method comprising:

[0041] Step S10, providing an array substrate, transferring near-infrared Micro-LED chips to the array substrate, alignment and die-bonding soldering, to form an array of near-infrared Micro-LED chips.

[0042] Step S20, preparing a color conversion layer on the near-infrared Micro-LED chip array, wherein the material of the color conversion layer includes a conversion fluorescent material and a rare earth material doped in the conversion fluorescent material, the Rare earth materials include one or more of rare earth fluorides, rare earth oxides, and rare earth oxyfluorides.

[0043] Preferably, the preparation method of the display panel further includes: step S30, preparing a planarization layer flush with the near-infrared Micro-LED chip array on the array substrate, and the planarization...

Embodiment 2

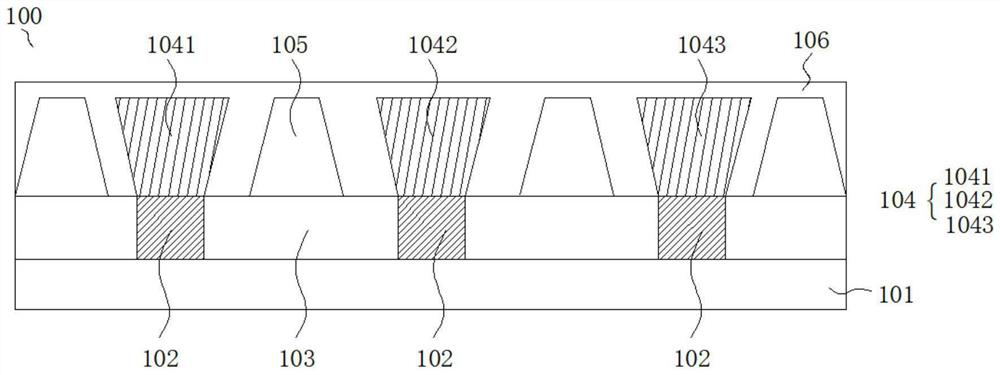

[0045] The preparation method of the display panel in the second embodiment further includes: step S30, preparing a second black matrix flush with the color conversion layer on the array substrate, the second black matrix is located on the near-infrared Micro -In the gap between the LED chip array and the color conversion layer; wherein, the cross-sectional shape of the red conversion layer, blue conversion layer and green conversion layer in the color conversion layer is rectangular, and the cross-sectional shape of the second black matrix It is an upright isosceles trapezoid.

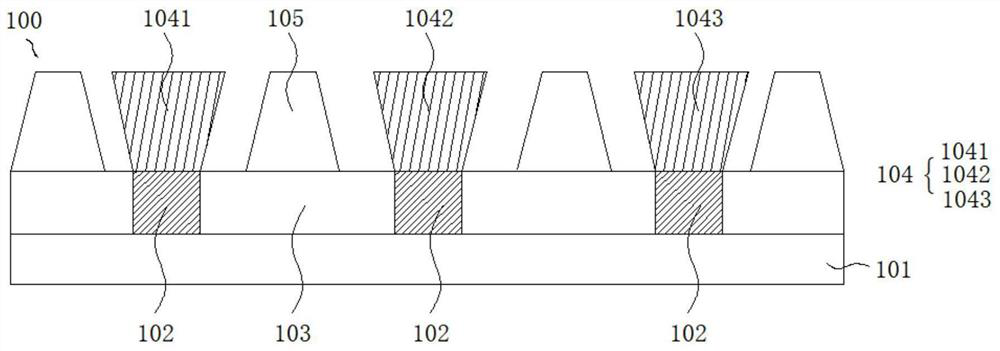

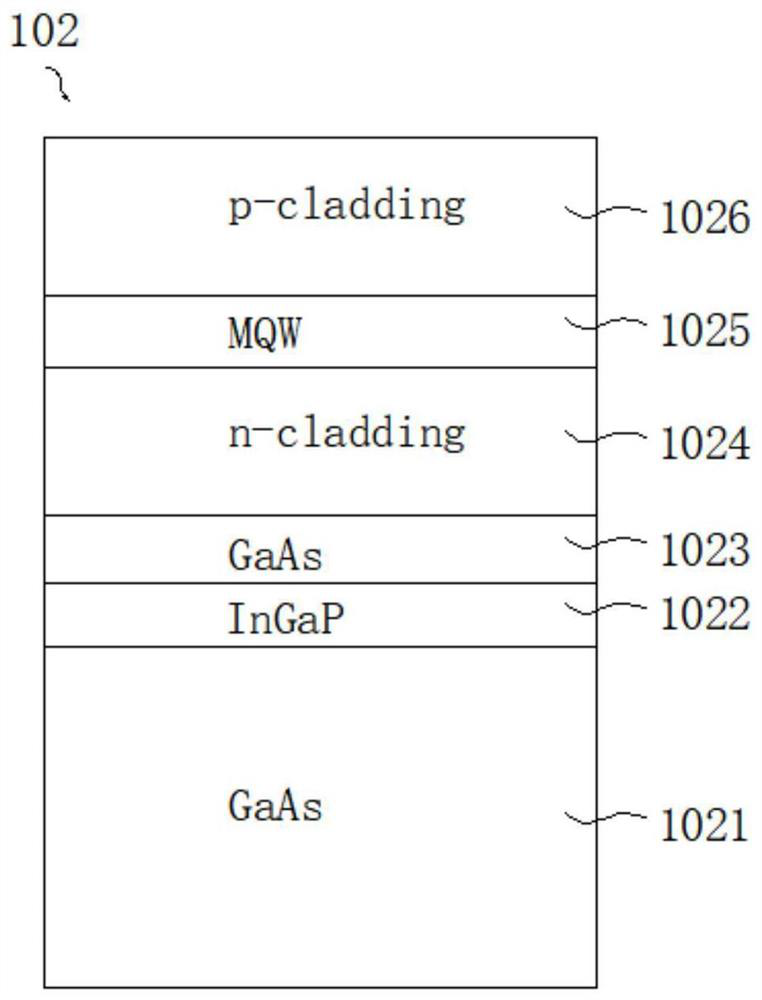

[0046] Figure 10 to Figure 12 It is the concrete preparation method of embodiment two. Such as Figure 10 As shown, the present invention provides an array substrate 101. The array substrate 101 is preferably a thin film transistor substrate. Several near-infrared Micro-LED chips 102 are transferred to the array substrate 101 by a fluid mass transfer method. The surface of the array substrate 101...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com