Switch cabinet

A switch cabinet and cabinet body technology, applied in the field of switch cabinets, can solve the problems of temperature rise in electrical contact parts, no heat dissipation system, heat dissipation, etc., and achieve the effect of reducing fan power, good heat dissipation effect, and realizing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

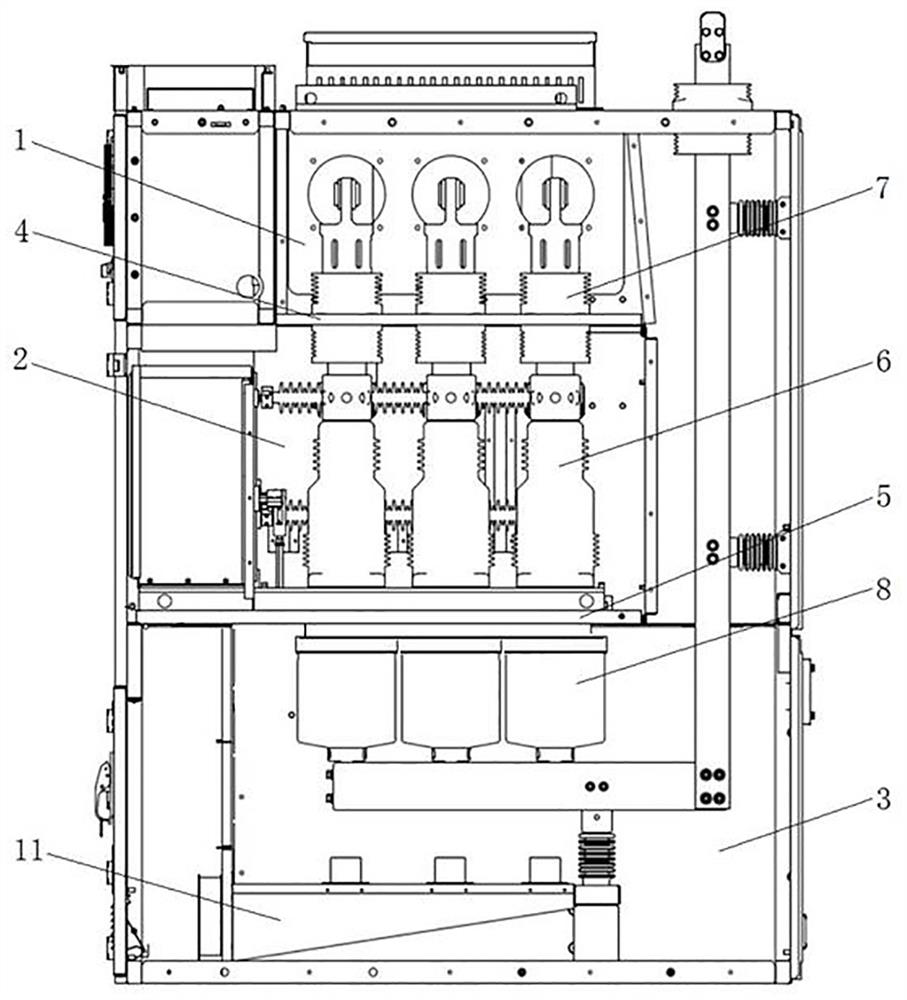

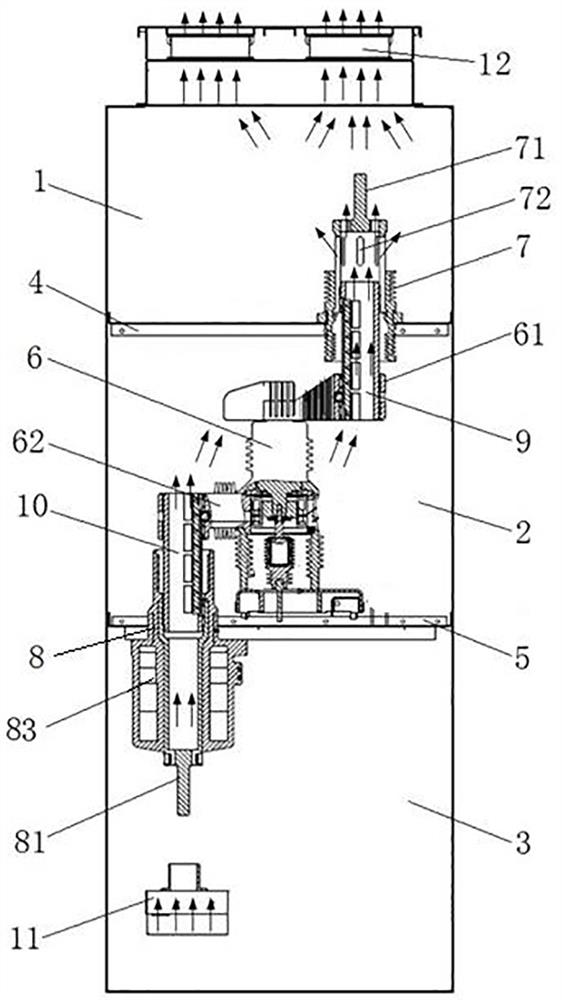

[0038] Such as figure 1 and figure 2 As shown, the switch cabinet includes a cabinet body, and the bus room 1, the circuit breaker room 2 and the cable room 3 are arranged in the cabinet in sequence from top to bottom. The bus room 1 and the circuit breaker room 2 are separated by an upper partition 4, and the circuit breaker The device chamber 2 and the cable chamber 3 are separated by a lower partition 5.

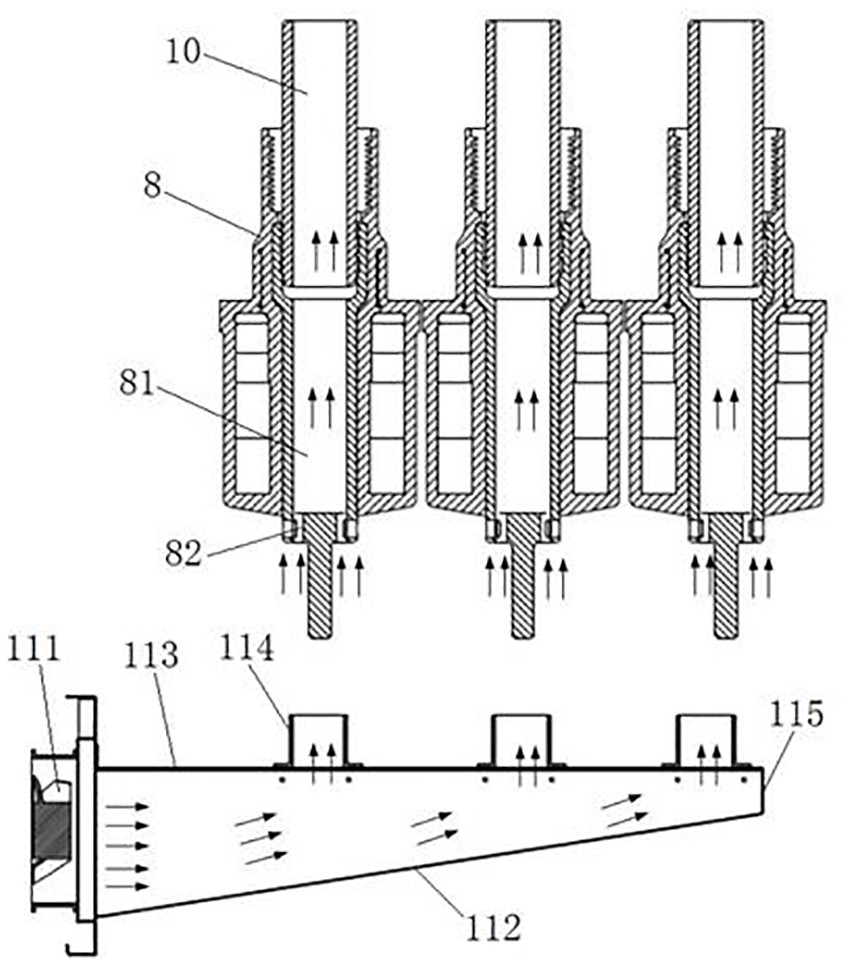

[0039] In this embodiment, the upper partition 4 is provided with an upper isolation sleeve 7, and the upper isolation sleeve 7 has an upper isolation static contact 71; the lower partition 5 is provided with a lower isolation sleeve 8, and the lower isolation sleeve 8 has Lower isolated static contact 81. Wherein, the upper isolating static contact 71 and the lower isolating static contact 81 are both hollow structures.

[0040] In this embodiment, a current transformer 83 is integrally formed on the lower isolating sleeve 8, which is designed in such a way that the ...

Embodiment 2

[0054] The difference between this embodiment and the first embodiment is that in the first embodiment, the heat dissipation fan includes an exhaust fan 12 and a blower 111 . In this embodiment, the cooling fan only includes a blower. In other embodiments, the cooling fan may only include a suction fan.

Embodiment 3

[0056] The difference between this embodiment and the first embodiment is that in the first embodiment, the air inlet channel is a wedge-shaped air channel. In this embodiment, the air inlet channel is a rectangular parallelepiped air channel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com