Tubular pile welding trolley control system and welding system

A welding trolley and control system technology, applied in welding equipment, welding accessories, manufacturing tools, etc., can solve the problems of unsuitable welding with drilling and pipe piles, reduce the difficulty of motion control and research and development costs, and realize productization and market effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

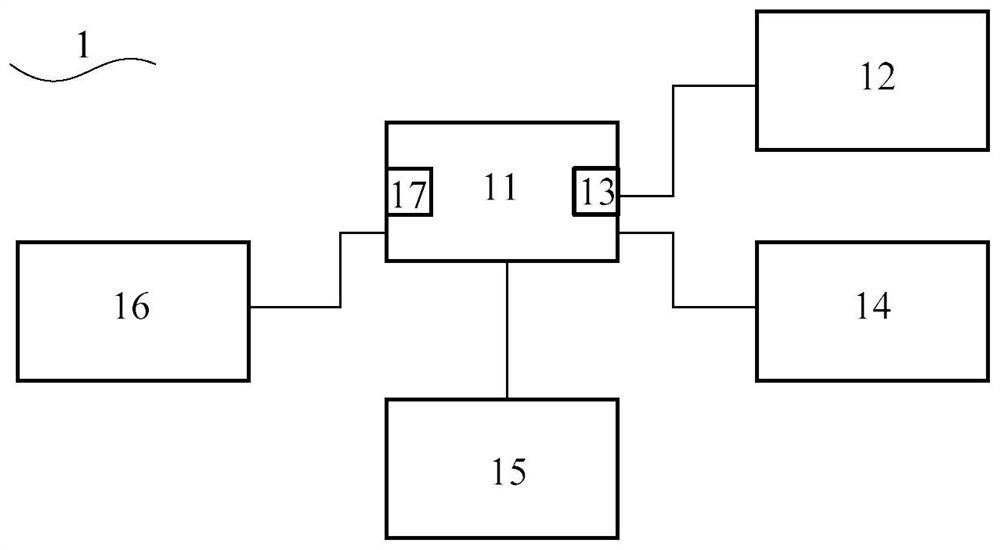

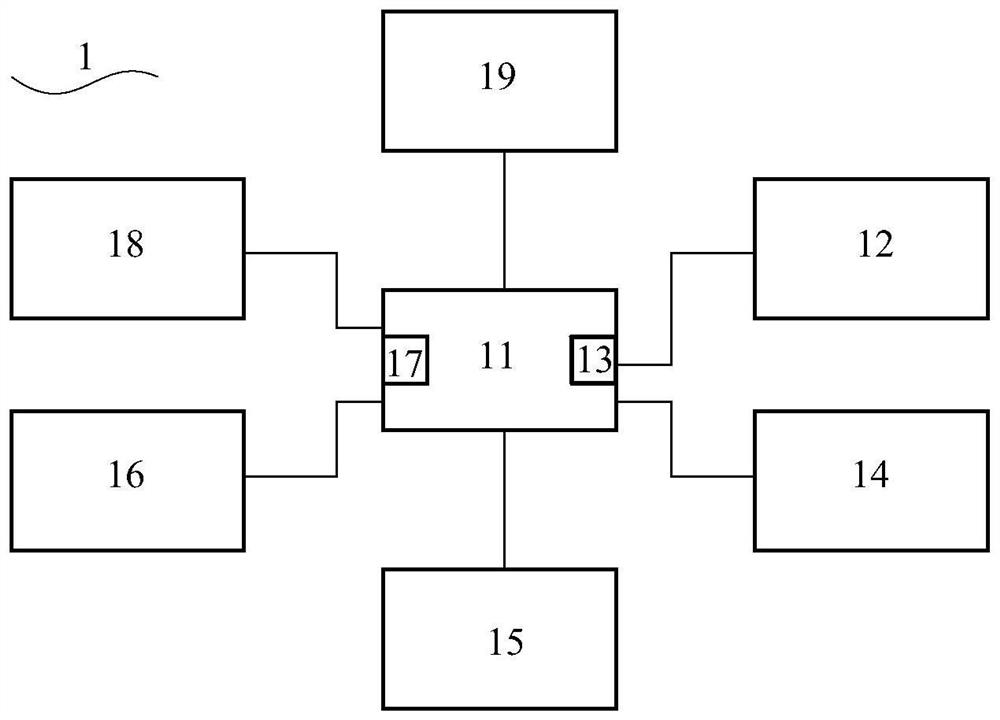

[0036] see figure 1As shown, the present invention provides a pipe pile welding trolley control system, the pipe pile welding trolley control system may include a controller 1, and the controller 1 includes: a main control module 11, a motion control module 12, an interface circuit 13, Seam tracking module 14, gas source control module 15, welding power supply control module 16 and hand-held instrument interface 17; wherein, the interface circuit 13 is arranged on the main control module 11, the interface circuit 13 is connected with the The module 11 is connected; the motion control module 12 is connected with the main control module 11, and communicates with the stepper motor (not shown) that drives the pipe pile welding trolley (not shown) to move through the interface circuit 13 connected, used to control the stepper motor to work according to the received motion control signal sent by the main control module 11, so as to control the movement of the pipe pile welding trol...

Embodiment 2

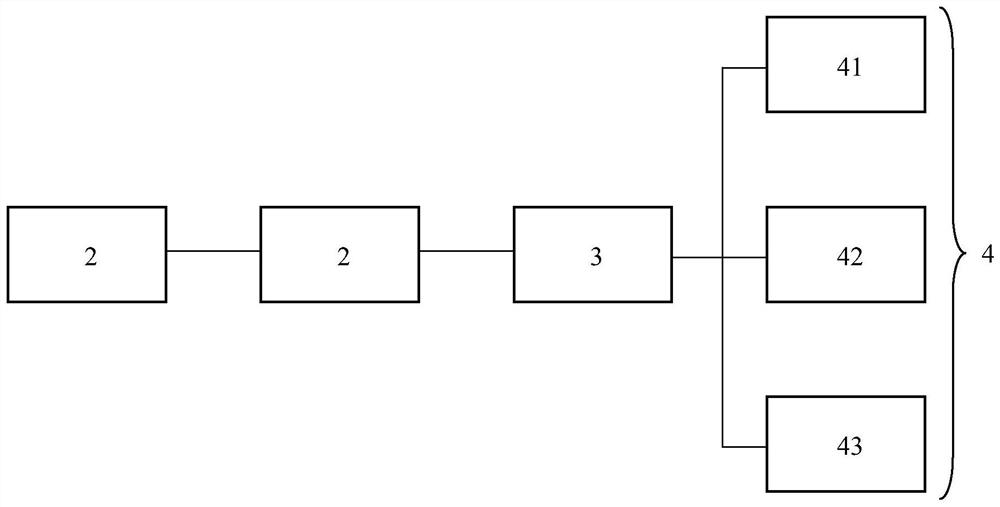

[0053] Please combine Figure 1 to Figure 3 , the present invention also provides a welding system, the welding system includes: the pipe pile welding trolley control system as described in any of the above schemes; the pipe pile welding trolley, the pipe pile welding trolley is connected with the controller 1 connected, for working under the control of the controller 1; a welding machine, the welding machine is located on the pipe pile welding trolley, and the welding machine is connected with the controller 1 for controlling Work under the control of the controller 1; gas source, the gas source is connected to the controller 1, and the gas source is used to provide welding gas through the welding gas supply pipeline under the control of the controller 1; the The welding gas supply pipeline is provided with a pressure gauge and a flow meter; a welding gun, the welding gun is located on the welding machine, and the welding gun is connected with the welding machine and the gas s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com