Degradation method of TPHP, biochar-inorganic mineral composite material and preparation method of biochar-inorganic mineral composite material

A technology of inorganic minerals and biochar, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve problems such as unfavorable large-scale promotion and application, expensive cobalt materials, complicated preparation process, etc., and achieve governance effects The effect of stability, low cost and wide source of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

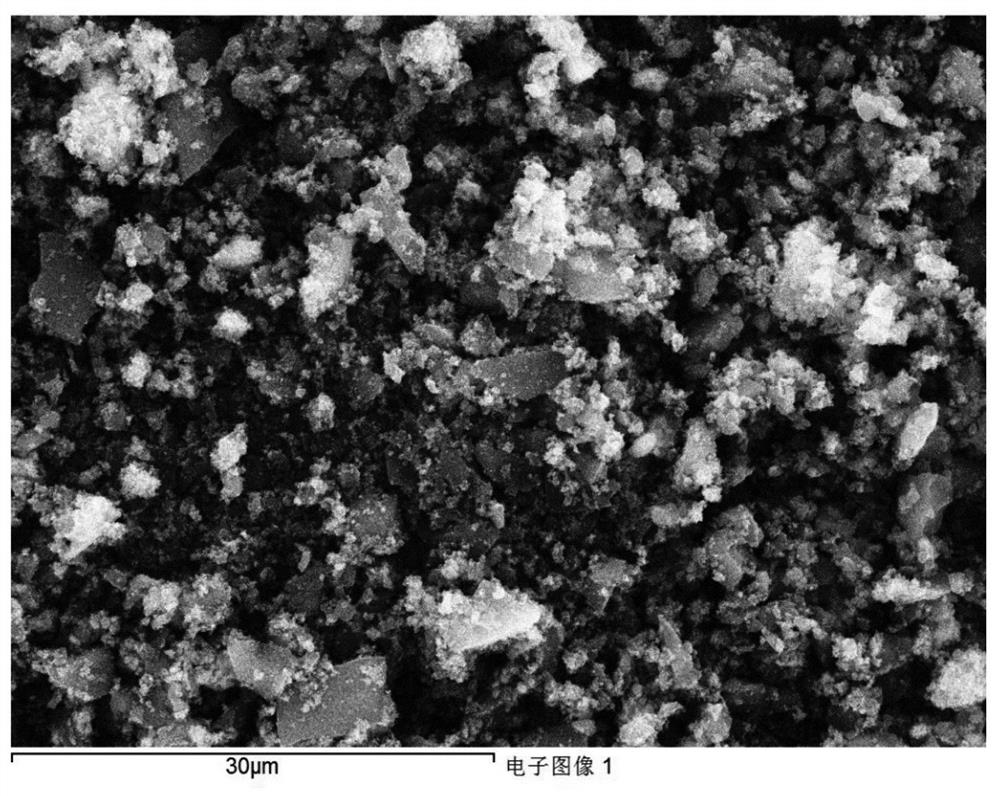

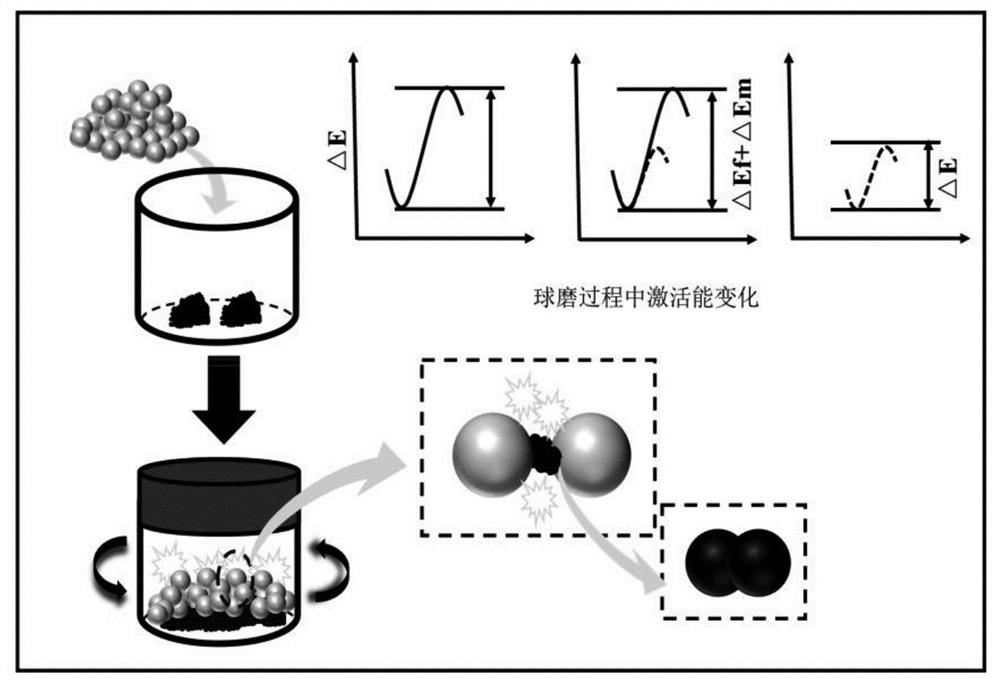

[0052] See attached figure 1 , figure 2 , the N-doped biochar-inorganic mineral composite material used to implement the TPhP (triphenyl phosphate) degradation method provided in this example is ball-milled modified Fe 2 o 3 One of @MBC or FeO(OH)@MBC, where MBC is self-derived N-doped biochar, and it is combined with inorganic mineral Fe 2 o 3 Or FeO(OH) powder was modified by ball milling at the same time.

[0053] see figure 1 , the Fe 2 o 3 Compared with traditional biochar materials, the microstructural characteristics of @MBC (or FeO(OH)@MBC) materials change more obviously. Due to the process of preparing biochar-inorganic minerals by ball milling, the original carbon skeleton structure of biochar is broken, and the particle size of biochar becomes smaller and has an irregular flaky fragment structure. More active sites can be exposed during the process. Inorganic mineral Fe 2 o 3 Or FeO(OH) is bound to the surface of the biochar fragment structure through ...

Embodiment 2

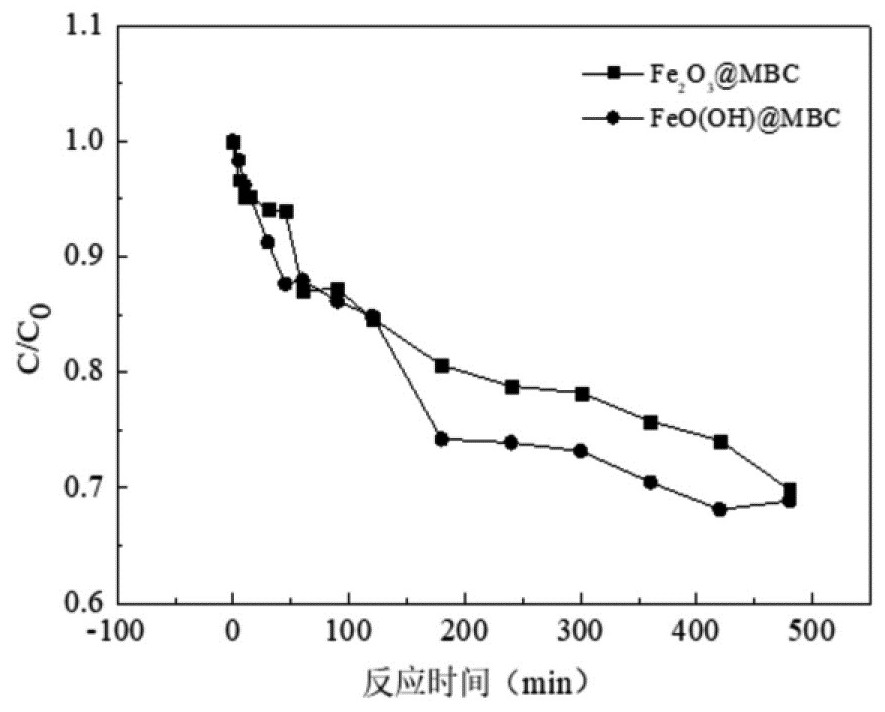

[0074] This example is a specific application of the technical solution provided in Example 1. The key point is to prepare various self-derived N-doped biochar MBCs obtained at different pyrolysis temperatures, and further prepare them as Fe 2 o 3 @MBC or FeO(OH)@MBC composite materials, and the performance and parameters (degradation time, degradation rate, maximum degradation rate, change trend, etc.) of various materials for catalysis, activation of PDS, adsorption, and degradation of TPhP were measured.

Embodiment 2-A

[0076] On the basis of the preparation method and preparation conditions of the composite material described in Example 1, the addition ratio of biochar and inorganic minerals (mass ratio of biochar to inorganic minerals) was selected to be 1:2 by secondary pyrolysis at 350°C, and the ball-milling ratio 1:100, the speed of ball milling modification is 500r / min, and the duration of ball milling modification is 12h. 2 o 3 @MBC and FeO(OH)@MBC were used as activators, and the degradation performance was determined.

[0077] To the TPhP sample solution with a measured concentration of 3.26 mg / L, a certain amount of biochar prepared with a secondary pyrolysis temperature of 350 °C, and its combination with inorganic minerals (Fe 2 o 3 , FeO(OH)) was added at a mass ratio of 1:2, the mass ratio of the composite material to the grinding ball was 1:100 during ball milling modification, the speed of the ball mill was 500r / min, and the cumulative time of ball milling was 12h. 2 o 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com