Method for continuously preparing pentamethylene diisocyanate

A technology of pentamethylene diisocyanate and o-dichlorobenzene, which is applied in the field of continuous preparation of pentamethylene diisocyanate by phosgene method, can solve the problems of no large-scale industrial production, low yield, many side reactions, etc., and achieve The effect of avoiding tar generation, increasing product yield, and reducing the formation of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

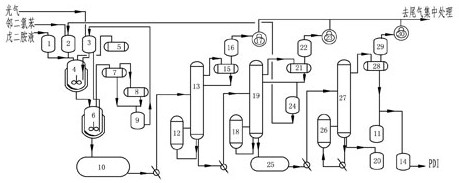

Image

Examples

Embodiment Construction

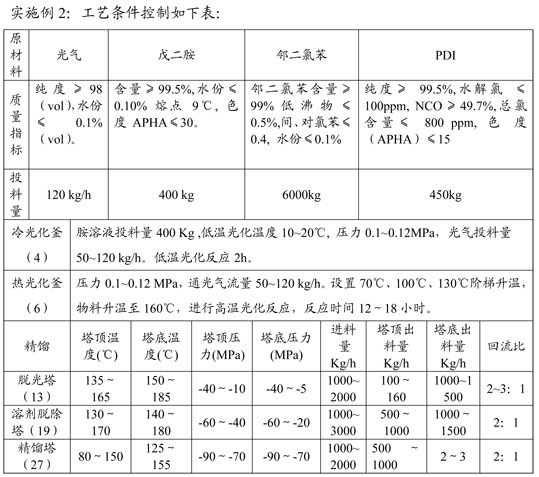

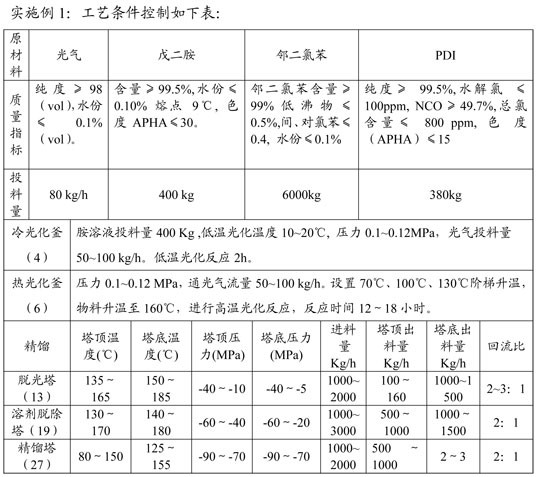

[0025] The following examples serve to further illustrate the method of the present invention. The spirit and scope of the present invention disclosed above are not limited by these examples.

[0026]

[0027] Operational steps according to the above conditions include:

[0028] a. Vaporize liquid phosgene, and the pressure of phosgene reaches 0.10-0.12MPa;

[0029] b. Operate the refrigerant and heat medium systems, so that the return temperature of the refrigerant is controlled at -10-10°C, and the return temperature of the heat medium is controlled at 140-180°C;

[0030] c. Put 100~500Kg of pentamethylenediamine and o-dichlorobenzene together for dehydration and put it to the 80% liquid level in the dehydration pentamethylenediamine solution tank 1, and put the dehydrated o-dichlorobenzene into the 80% liquid level in the dehydration solvent tank 2. According to the liquid level, according to the ratio of amine and solvent 1:15~20, put into the cold photochemical kettl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com