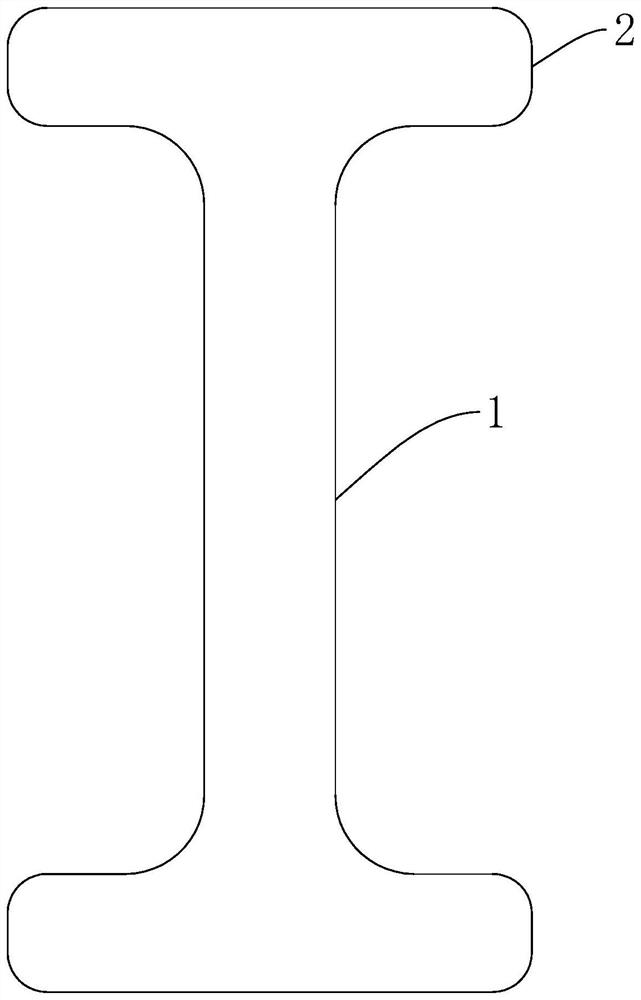

Glass fiber reinforced polyurethane material, support beam and preparation process of support beam

A technology of polyurethane material and supporting beam, which is applied in the direction of supporting the roof beam of mine roof, mining equipment, earth-moving drilling, etc. It is not easy to crack and reduces the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides a support beam. The support beam in this embodiment is made of glass fiber reinforced polyurethane material. The glass fiber reinforced polyurethane material includes the following components by weight: 82kg of glass fiber yarn and its fabric, 20kg of polyol and isocyanate mixed polyurethane resin, 1kg of carbon-based nanomaterial, and 2kg of dispersant. Among them, carbon-based nanomaterials use TUBALL TM The aspect ratio of single-walled carbon nanotubes and carbon-based nanomaterials is 3125:1; glass fiber yarn and its fabrics include 70kg of glass fiber yarn and 12kg of glass fiber fabric, and BYK-163 is selected as the dispersant.

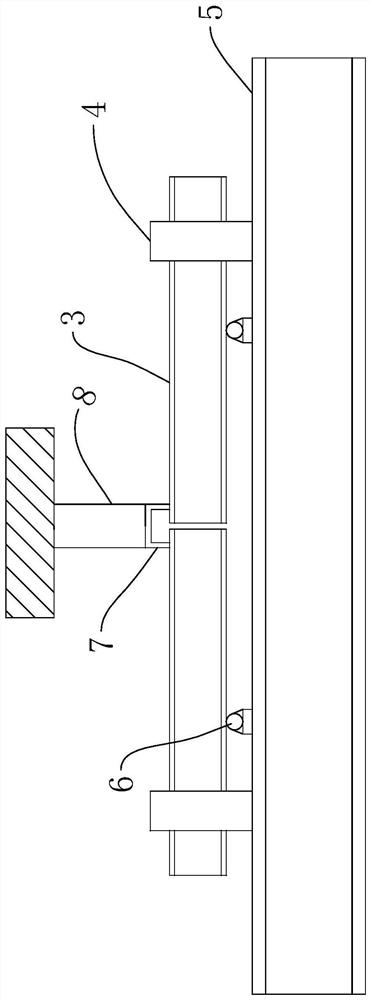

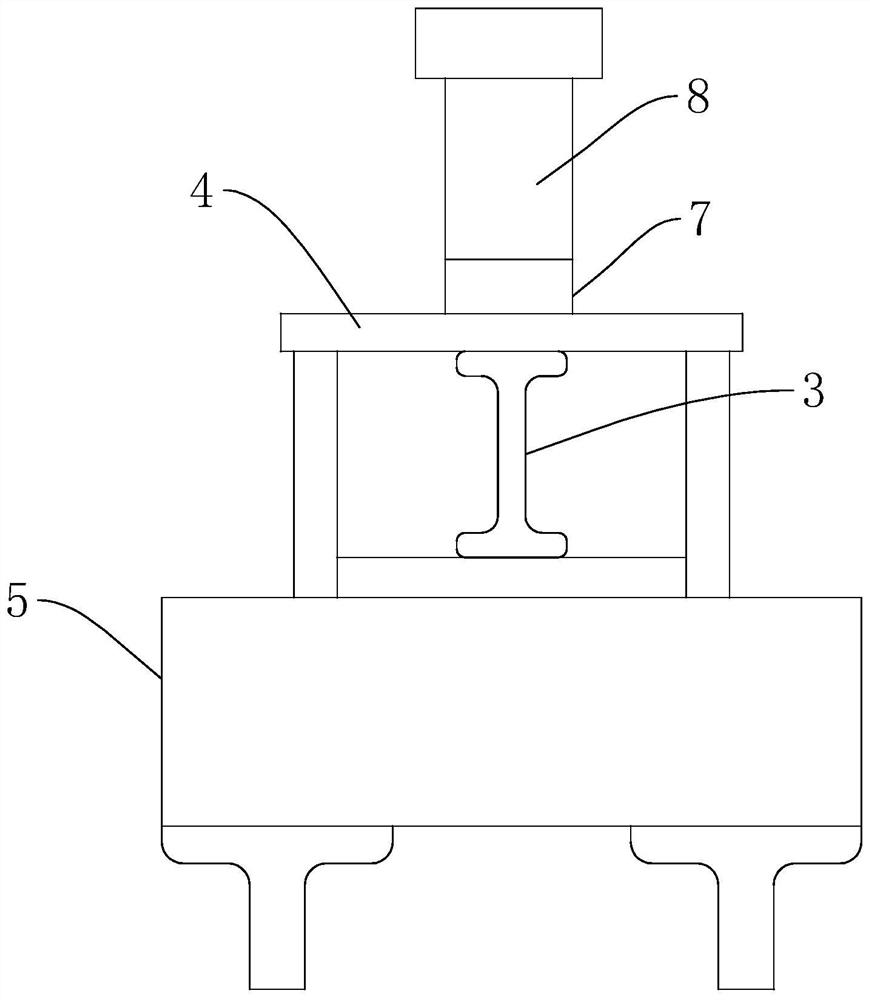

[0048] The supporting beam of the present embodiment is prepared according to the following steps:

[0049] Mixing stage: Add polyol and isocyanate mixed polyurethane resin, carbon-based nanomaterials and dispersant into the mixer, and stir evenly to obtain a two-component polyurethane resin mixture;

[0050] ...

Embodiment 2-10

[0055] As shown in Table 1, the difference between Examples 2-10 and Example 1 is that the proportioning of raw materials is different.

[0056] Table 1 Raw material weight percentage ratio table of embodiment 2-10

[0057]

[0058]

Embodiment 11

[0060] The difference between this embodiment and Embodiment 1 is that the glass fiber yarn and its fabric include 67 kg of glass fiber yarn and 13 kg of glass fiber fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap