Method for producing hyaluronic acid

A technology of hyaluronic acid and conditions, applied in the field of hyaluronic acid production, can solve the problems of unfavorable bacterial growth or product accumulation at constant pH, unfavorable hyaluronic acid synthesis, unfavorable production amplification and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Take out the glycerin tube strain from the ultra-low temperature refrigerator, melt it in a 37°C water bath or in the palm of your hand, inoculate it into the seed medium at a volume ratio of 1%, and cultivate it at 200-220 rpm at 36.5°C for 17.5-18 hours. Before the end of the culture, perform a Gram staining microscope. After there is no abnormality, inoculate a 15L fermenter with a ventilation rate of 0.5-1vvm, stirring at 100-600rpm, and ferment at 37°C for 30h.

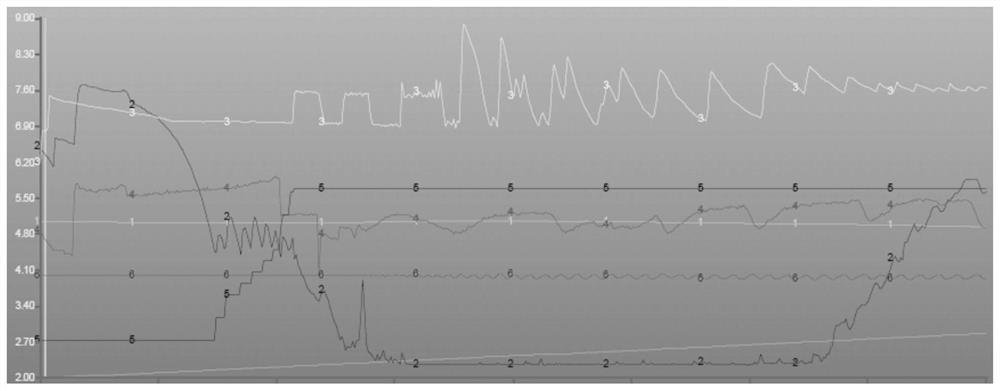

[0035] The fermenter adopts the following pH control strategy:

[0036] Early stage of fermentation (0-6 hours): After inoculation, the pH of the fermentation broth naturally drops to 6.7, and the pH of the fermentation broth is maintained at 6.7 by 20-30% NaOH alkali control. In the middle stage of fermentation (6-12h), the pH is increased by 0.1 every 1h from 6h until the pH rises to 7.4, and the pH is constantly controlled to 7.4. In the middle and late stages of fermentation (12 to 30 hours), the pH o...

Embodiment 2

[0038] The fermenter adopts the following pH control strategy:

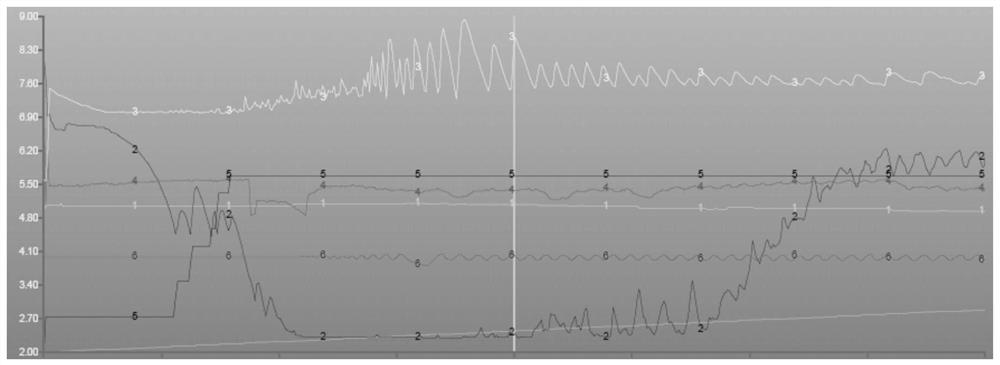

[0039] Early stage of fermentation (0-6h): After inoculation, the pH of the fermentation broth naturally drops to 7.2, and the pH of the fermentation broth is maintained at 7.2 by alkali control. In the middle stage of fermentation (6-12h), the pH is increased by 0.2 every 1h from 6h until the pH rises to 7.6, and the pH is constantly controlled to 7.6. In the middle and late stages of fermentation (12-30h), by changing the parameters of the alkali control and automatic control program, the constant rate of the peristaltic pump and the opening time of the solenoid valve, the pH of the fermentation process is kept in a state of continuous fluctuation. Finish. pH control curve such as figure 1 shown. The results showed that the bacterial cell concentration (OD660) of the 12h intermediate sample was 5.42, and the output of hyaluronic acid in the tank was 8.52g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com