A microbial fermentation process amplification platform technology

A technology for microbial fermentation and fermentation process, applied in the field of microbial fermentation process amplification platform technology, can solve the problems of not considering the molecular level metabolic changes in the microbial fermentation process, the mismatch of microbial growth states, and the failure to consider the growth characteristics of microorganisms, and achieve a high degree of automation. , Wide range of applications, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] An amplified platform technology for microbial fermentation process, which selects marker metabolites during the fermentation process to reflect the growth status of microorganisms and the condition of the fermentation medium, and improves the stirring reaction by controlling the changes of marker metabolites and combining with fluid dynamics calculation design The size and structure of the vessel increase the gas holdup rate and decrease the concentration of marker metabolites; optimize the fermentation conditions and scale up the fermentation process.

[0076] This technology is applied to the fermentation of Saccharomyces cerevisiae to produce glutathione, co-production of glutathione and ergosterol, S-adenosyl-L-methionine; Streptococcus zooepidemicus to produce hyaluronic acid.

[0077] The marked metabolites are ethanol, glycerol, lactic acid, and acetic acid.

[0078] The marker metabolites are monitored, and the monitoring method is online automatic detection an...

Embodiment 2

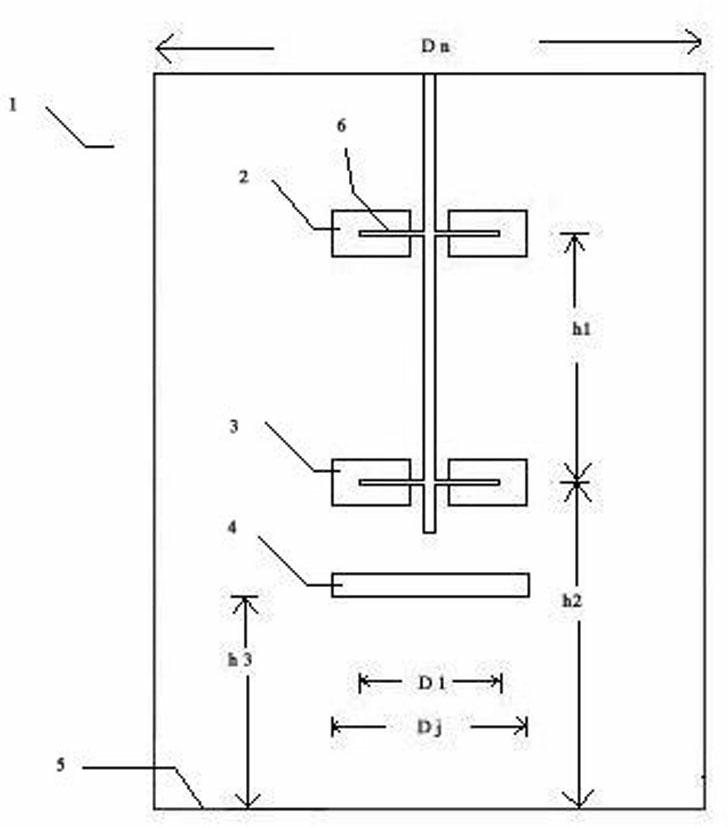

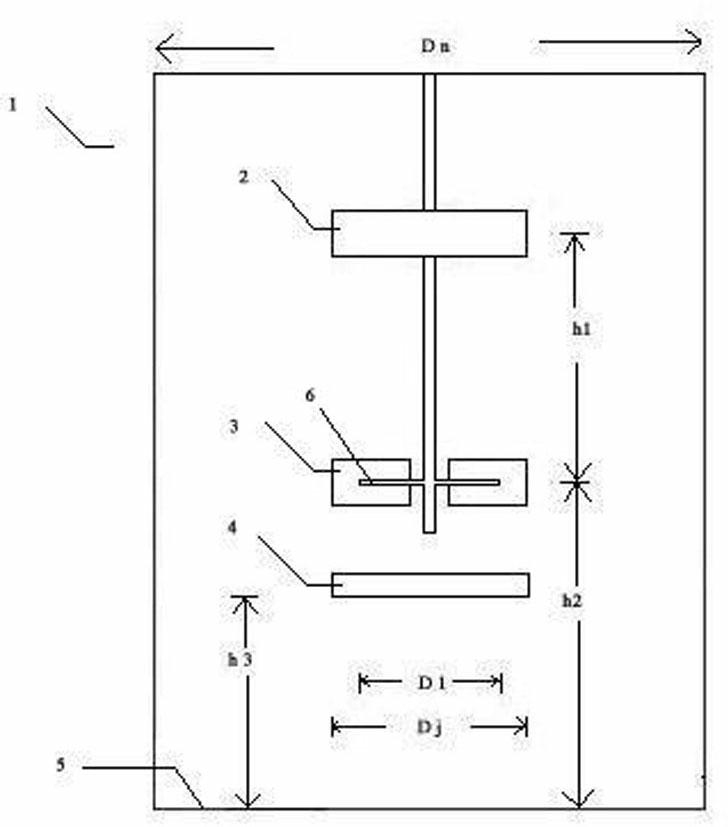

[0091] On the basis of Example 1, this example details the improvement of the reactor through fluid dynamics calculation design.

[0092]Theoretically speaking, the basic process of applying computational fluid dynamics to agitation design to improve fermentation is as follows:

[0093] A. Analyze the fermentation process to obtain the basic requirements and parameters of fermentation for stirring. Firstly, the fermentation process is analyzed to obtain the basic requirements of the fermentation process for stirring, such as gas holdup, mixing time, shear force, etc. Then the physical and chemical parameters of the fermentation broth in the fermentation process, such as viscosity, temperature, thermal conductivity, etc., are obtained through experiments. Determine the volume of the fermenter, select possible agitators, determine other internals (such as air distributors, etc.), and meet other requirements to finally determine the computational domain.

[0094] B. Computation...

Embodiment 3

[0177] This example is a preferred solution based on Example 1 and Example 2, which is applied to the production of glutathione by Saccharomyces cerevisiae.

[0178] After activating the slant of strains stored in the laboratory at 28°C for 12 hours, scrape a ring of Saccharomyces cerevisiae and inoculate it into a 250 mL shaker flask containing 50 mL of seed liquid medium, at 25~30°C, 100~ Cultivate for 16-24 hours under the condition of 180 rpm to obtain yeast seed liquid. The formula of the seed liquid medium was: 2 g of glucose, 1 g of yeast powder, 2 g of beef peptone, and the volume was adjusted to 100 mL with water.

[0179] A 2L fermentation medium was prepared in a 5L stirred fermenter, and the medium formula was: glucose 60 g / L, yeast powder 15 g / L, molasses 16 g / L, malt powder 5 g / L, corn steep liquor 9 g / L, MgSO 4 ·7H 2 O 9.8 g / L, (NH 4 ) 2 HPO 4 9 g / L, K 2 HPO 4 1 g / L, KH 2 PO 4 1 g / L, MnSO 4 30 mg / L, FeSO 4 ·7H 2 O 30 mg / L, CuSO 4 ·5H 2 O 34 mg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com