Method for producing hyaluronic acid by fermentation and application of method

A technology of hyaluronic acid and fermented liquid, applied in the field of fermentation, can solve the problems of affecting the quality of hyaluronic acid, high production cost, low molecular weight of hyaluronic acid, etc., so as to be beneficial to growth and metabolism, avoid the risk of bacterial contamination, The effect of shortening the fermentation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

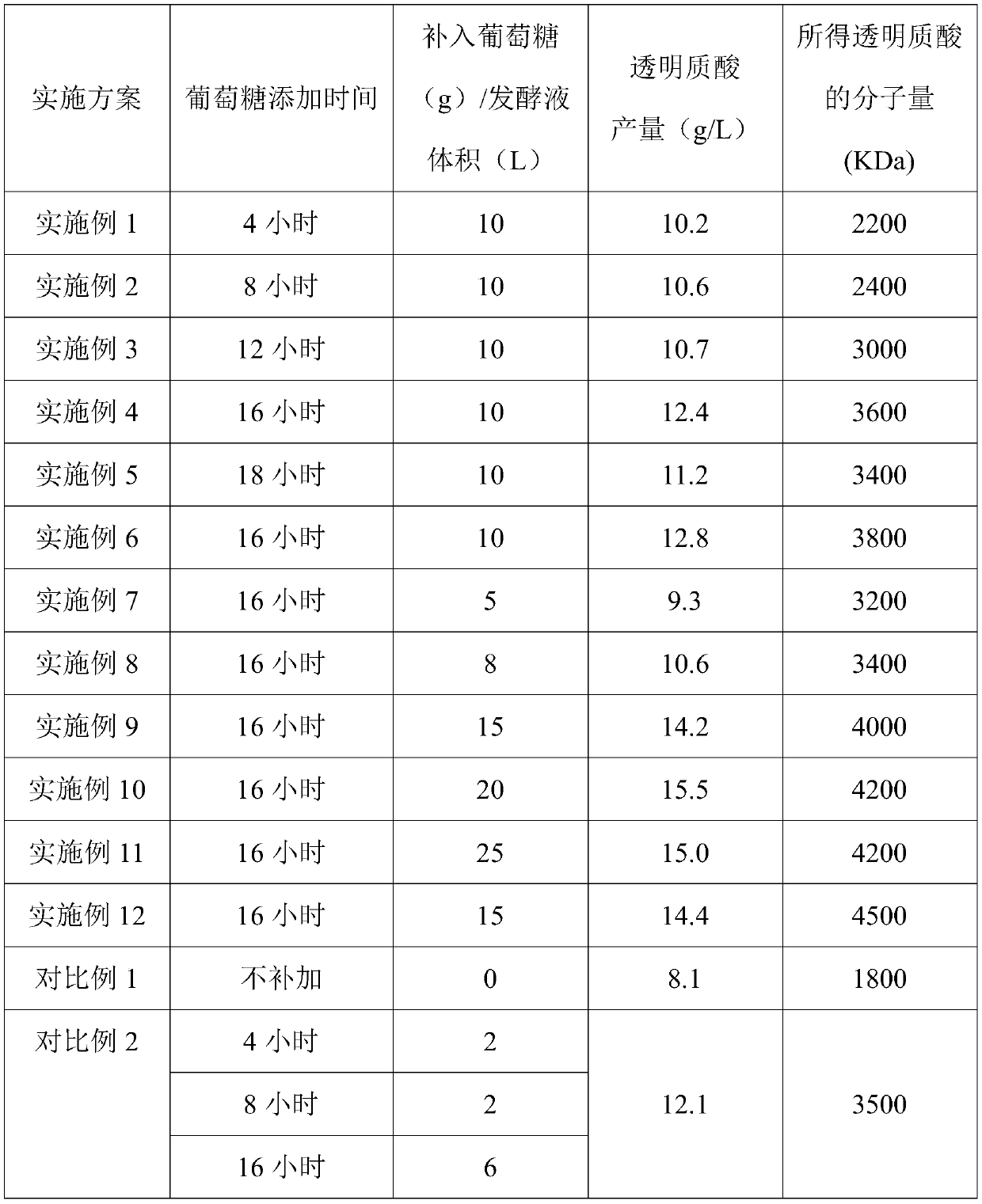

Embodiment 1

[0049] This embodiment provides a method for producing hyaluronic acid by fermentation, comprising the following steps:

[0050] 1. Using Streptococcus zooepidemicus as the fermentation strain, inoculate Streptococcus zooepidemicus on the seed solid medium for cultivation, and cultivate at 33°C for 16 hours;

[0051] 2. Inoculate the Streptococcus zooepidemicus into the shake flask seed medium for culture, shake and culture at 33°C for 12 hours, and obtain the Streptococcus zooepidemicus shake flask seed culture solution;

[0052] 3. Inoculate the shake flask seed culture solution of Streptococcus zooepidemicus into the seed tank culture medium for cultivation, the cultivation temperature is 33°C, adjust the pH of the culture solution with 30% sodium hydroxide to maintain it at pH 7.5, and cultivate for 12 hours to obtain Streptococcus zooepidemicus Seed tank seed culture solution;

[0053] 4. Inoculate the seed culture solution of the Streptococcus zooepidemicus seed tank in...

Embodiment 2

[0056] Same as Example 1, the difference is that, in the 8th hour after being transferred to the fermentation medium, 10 g of glucose was supplemented per liter of fermentation broth; the yield of the obtained hyaluronic acid was 10.6 g / L, and the molecular weight of the hyaluronic acid was 2400KDa.

Embodiment 3

[0058] Same as Example 1, the difference is that, at the 12th hour after being transferred to the fermentation medium, 10 g of glucose was supplemented per liter of fermentation broth; the yield of the obtained hyaluronic acid was 10.7 g / L, and the molecular weight of the hyaluronic acid was 3000KDa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com