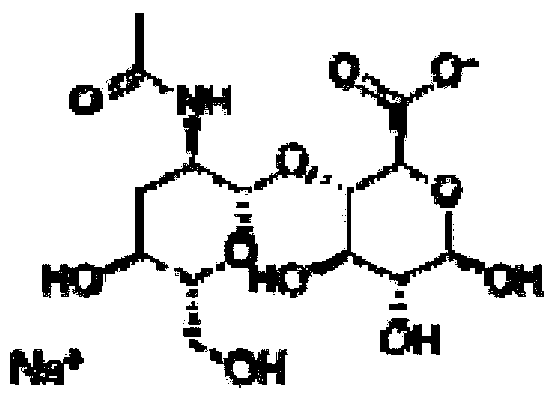

Method for improving fermentation yield of hyaluronic acid

A technology for hyaluronic acid and yield, which is applied in the field of improving hyaluronic acid fermentation yield, can solve problems such as product quality decline, limited application, easy to break hyaluronic acid molecules, etc., and achieves the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

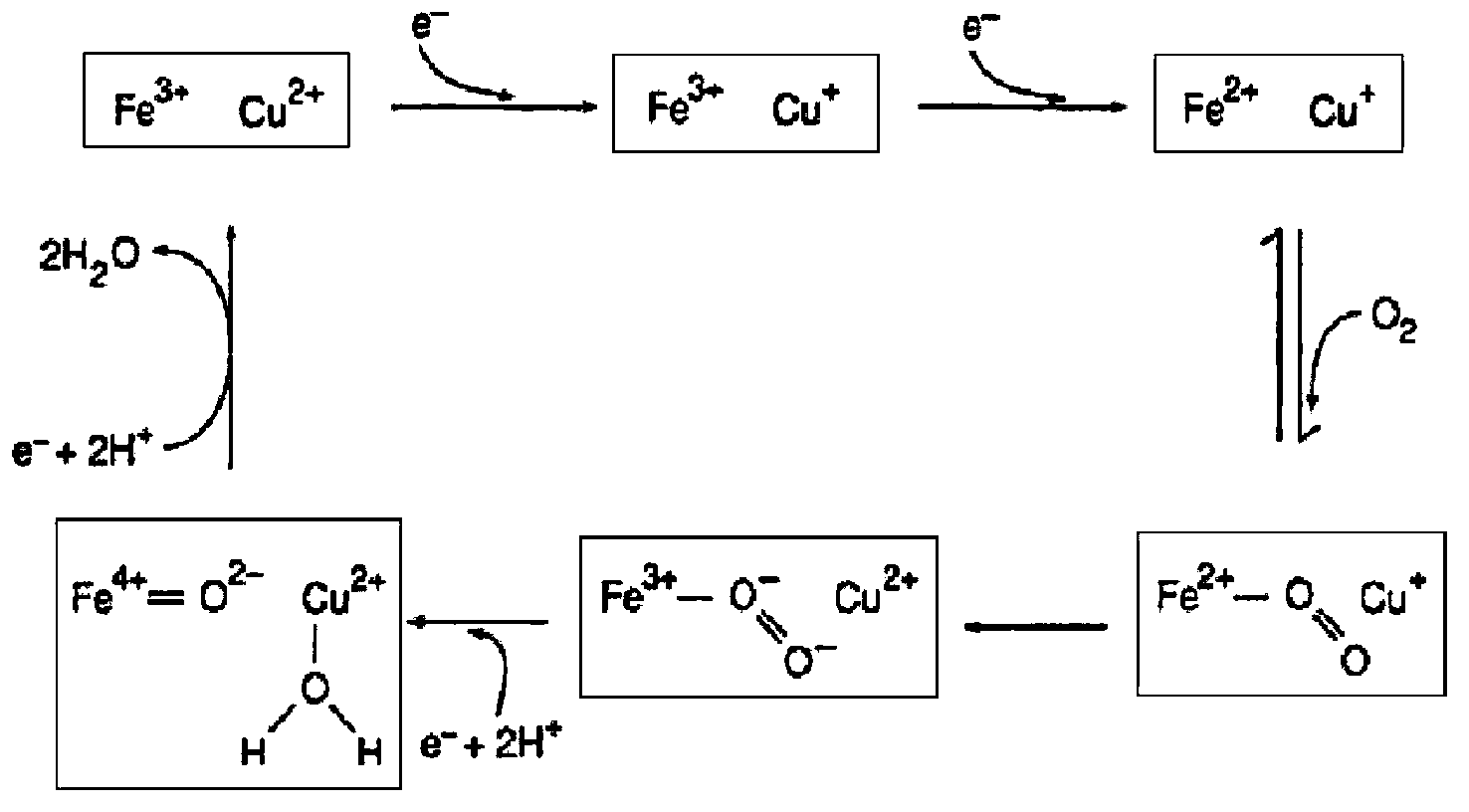

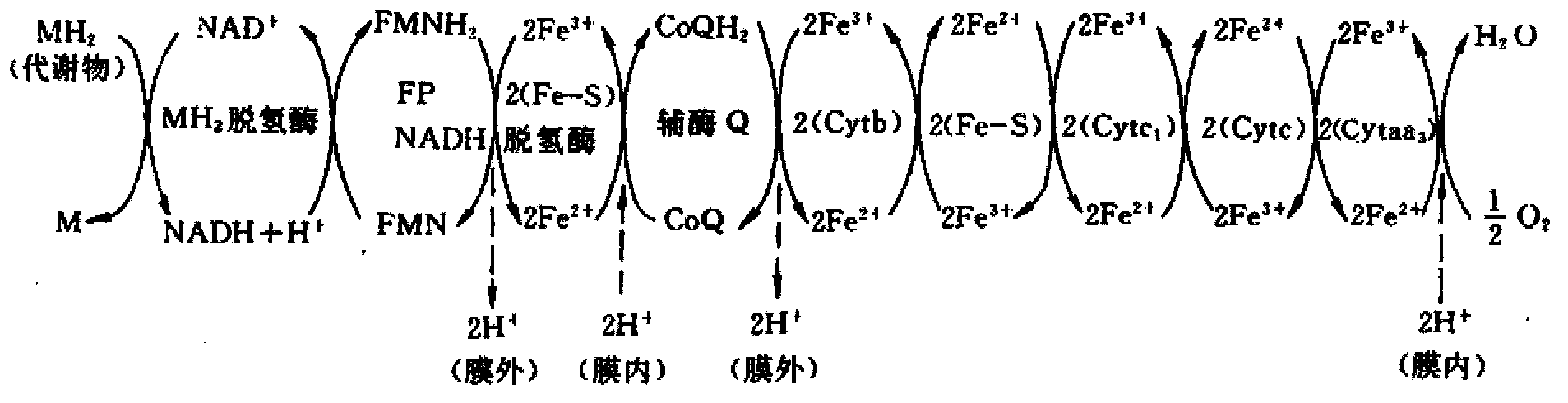

Method used

Image

Examples

Embodiment 1

[0027] Streptococcus zooepidemicus was used as hyaluronic acid fermentation strain. Add ferrous ammonium sulfate and copper ammonium sulfate to the medium used in the traditional method. The amount of ammonium ferrous sulfate added is 0.01% of the mass of the medium, and the amount of ammonium copper sulfate added is 0.05% of the mass of the medium.

[0028] The yield of hyaluronic acid was 1.37g / L, and the yield increased by about 30.4%.

Embodiment 2

[0030] Streptococcus zooepidemicus was used as hyaluronic acid fermentation strain. Ferrous ammonium sulfate and copper ammonium sulfate were added to the medium used. The amount of ammonium ferrous sulfate added is 0.1% of the mass of the medium, and the amount of ammonium copper sulfate added is 0.1% of the mass of the medium.

[0031] The yield of hyaluronic acid was 1.40g / L, and the yield increased by about 33.3%.

Embodiment 3

[0033] Streptococcus zooepidemicus was used as hyaluronic acid fermentation strain. Ferrous ammonium sulfate and copper ammonium sulfate were added to the medium used. The amount of ammonium ferrous sulfate added is 0.05% of the mass of the medium, and the amount of ammonium copper sulfate added is 0.03% of the mass of the medium.

[0034] The yield of hyaluronic acid was 1.41g / L, and the yield increased by about 34.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com