Drug-loaded polydopamine coated nanofiber dressing and preparation method thereof

A nanofiber, polydopamine technology, applied in the direction of fiber chemical characteristics, medical science, single-component polyester rayon, etc., can solve the problems of decreased activity of antibacterial drugs, spinning difficulties, etc., to speed up healing and speed up wound healing. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

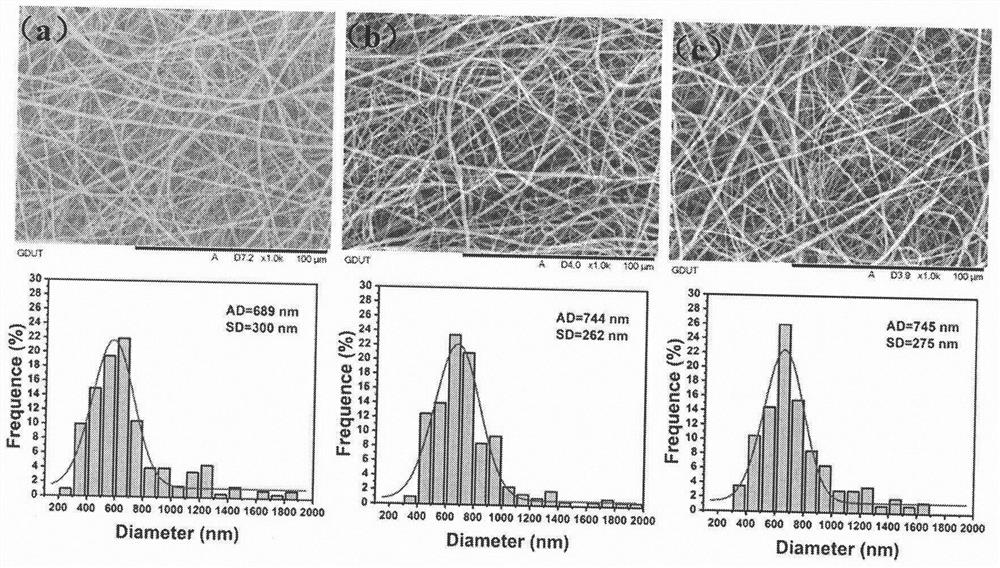

Image

Examples

Embodiment 1

[0025] (1) Preparation of spinning solution: take polycaprolactone with a molecular weight of 70000-90000 and add it to chloroform / methanol, the volume ratio of chloroform to methanol is 2:1, stir under the condition of magnetic stirring, stir The rotational speed of the method is 300-400 rpm, the stirring time is 6-12 hours, and the solution concentration of polycaprolactone is 12% (w / v).

[0026] (2) Electrospinning the spinning solution to obtain the matrix material of the drug-loaded polydopamine-coated nanofiber dressing.

[0027] The electrospinning process is as follows:

[0028] Step 1: Adjust the ambient temperature and humidity in the operating room to ensure that the spinning environment temperature is 20°C to 40°C and the humidity is within the range of 50% to 70%.

[0029] Step 2: Take a piece of silicone oil paper, paste the silicone oil paper on the roller collector, completely cover the roller collector, the diameter of the roller collector is 10cm.

[0030] ...

Embodiment 2

[0047] (1) Preparation of spinning solution: take polycaprolactone with a molecular weight of 70000-90000 and add it to chloroform / methanol, the volume ratio of chloroform to methanol is 2:1, stir under the condition of magnetic stirring, stir The rotational speed of the method is 300-400 rpm, the stirring time is 6-12 hours, and the solution concentration of polycaprolactone is 12% (w / v).

[0048] (2) Electrospinning the spinning solution to obtain the matrix material of the drug-loaded polydopamine-coated nanofiber dressing.

[0049] The electrospinning process is as follows:

[0050] Step 1: Adjust the ambient temperature and humidity in the operating room to ensure that the spinning environment temperature is 20°C to 40°C and the humidity is within the range of 50% to 70%.

[0051] Step 2: Take a piece of silicone oil paper, paste the silicone oil paper on the roller collector, completely cover the roller collector, the diameter of the roller collector is 10cm.

[0052] ...

Embodiment 3

[0069] (1) Preparation of spinning solution: take polycaprolactone with a molecular weight of 70000-90000 and add it to chloroform / methanol, the volume ratio of chloroform to methanol is 2:1, stir under the condition of magnetic stirring, stir The rotational speed of the method is 300-400 rpm, the stirring time is 6-12 hours, and the solution concentration of polycaprolactone is 12% (w / v).

[0070] (2) Electrospinning the spinning solution to obtain the matrix material of the drug-loaded polydopamine-coated nanofiber dressing.

[0071] The electrospinning process is as follows:

[0072] Step 1: Adjust the ambient temperature and humidity in the operating room to ensure that the spinning environment temperature is 20°C to 40°C and the humidity is within the range of 50% to 70%.

[0073] Step 2: Take a piece of silicone oil paper, paste the silicone oil paper on the roller collector, completely cover the roller collector, the diameter of the roller collector is 10cm.

[0074] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com