Integrated refractory wastewater treating and reusing device and sewage treatment method

A technology for wastewater treatment and refractory degradation, which is applied in the fields of oxidized water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc. problems, to achieve the effect of inhibiting the attachment of pollutants, reducing floor space, saving investment and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

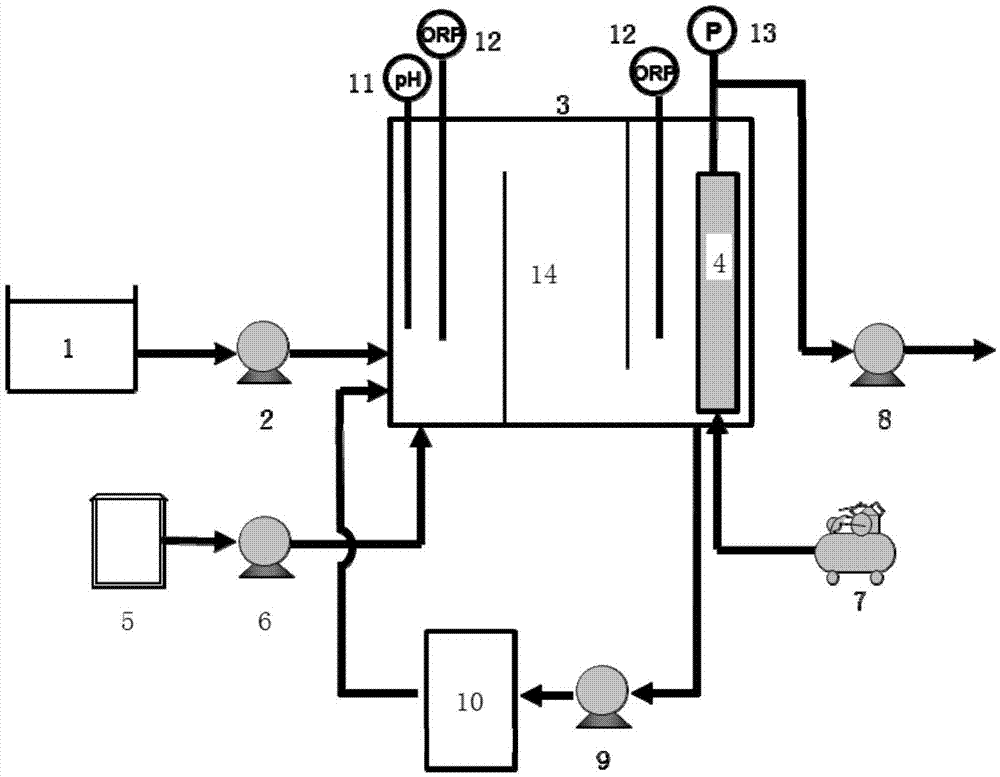

[0040] This implementation provides an integrated refractory wastewater treatment and reuse device, specifically as figure 1 shown.

[0041] An integrated refractory wastewater treatment and reuse device in this implementation includes:

[0042] Water inlet tank 1, water inlet pump 2, reactor 3, membrane module 4, chemical tank 5, chemical pump 6, blower 7, water outlet pump 8, catalyst circulation pump 9, catalyst regeneration device 10, pH and temperature sensor 11, ORP sensor 12 , pressure sensor 13 and baffle plate 14;

[0043] Among them, two baffle plates are arranged inside the reactor 3, and the reactor is divided into three compartments; the third compartment is provided with a membrane module 4 communicated with the water outlet pump 8, and a pipe connected between the outlet pump 8 and the membrane module 4 A pressure sensor 13 is provided on the road;

[0044] A pH and temperature sensor 11 is provided in the first compartment of the reactor 3; an ORP sensor 12 ...

Embodiment 2

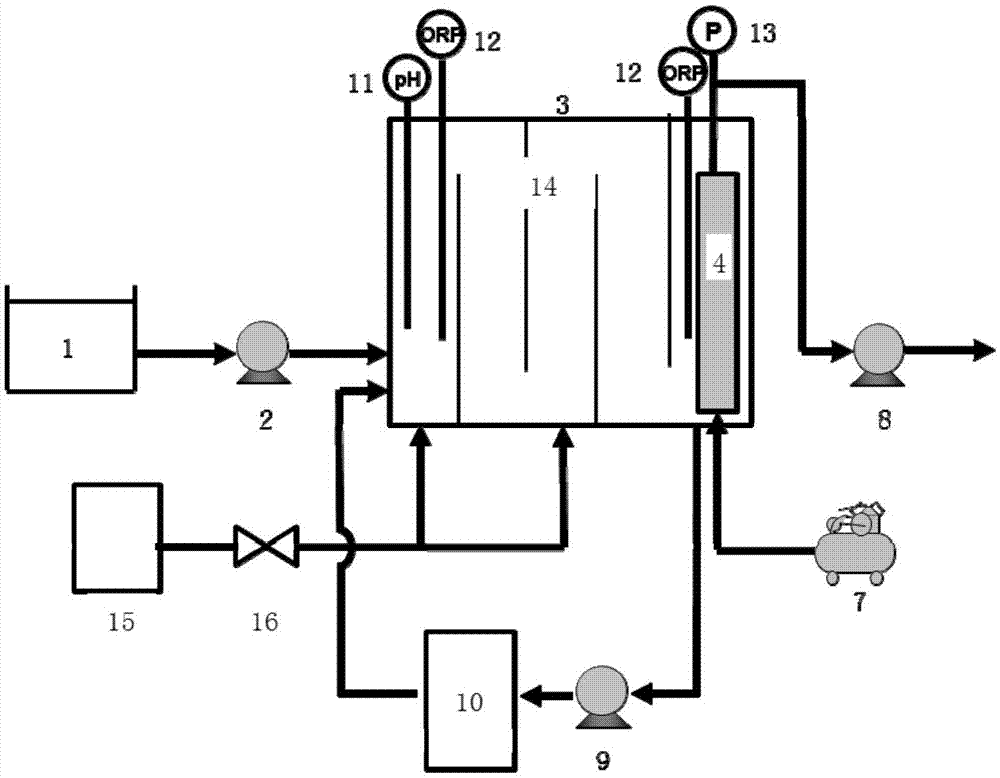

[0057] This implementation provides an integrated refractory wastewater treatment and reuse device, specifically as figure 2 shown.

[0058] An integrated refractory wastewater treatment and reuse device in this implementation includes:

[0059] Water inlet tank 1, water inlet pump 2, reactor 3, membrane module 4, blower 7, water outlet pump 8, catalyst circulation pump 9, catalyst regeneration device 10, pH and temperature sensor 11, ORP sensor 12, pressure sensor 13, baffle plate 14. Ozone generator 15 and gas flow valve 16;

[0060] Among them, the inside of the reactor 3 is provided with four baffles, which divide the reactor into five compartments; the fifth compartment is provided with a membrane module 4 connected with the outlet pump 8, and the pipe connected between the outlet pump 8 and the membrane module 4 A pressure sensor 13 is provided on the road;

[0061] The first grid of the reactor 3 is provided with a pH and temperature sensor 11; an ORP sensor 12 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com