High-strength novel heat insulation board

An insulation board, high-strength technology, applied in the direction of insulation, building components, sound insulation, etc., can solve the problems of not having sound insulation, insulation board damage, insulation board support, etc., to enhance insulation effect, improve stability, and good compressive performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

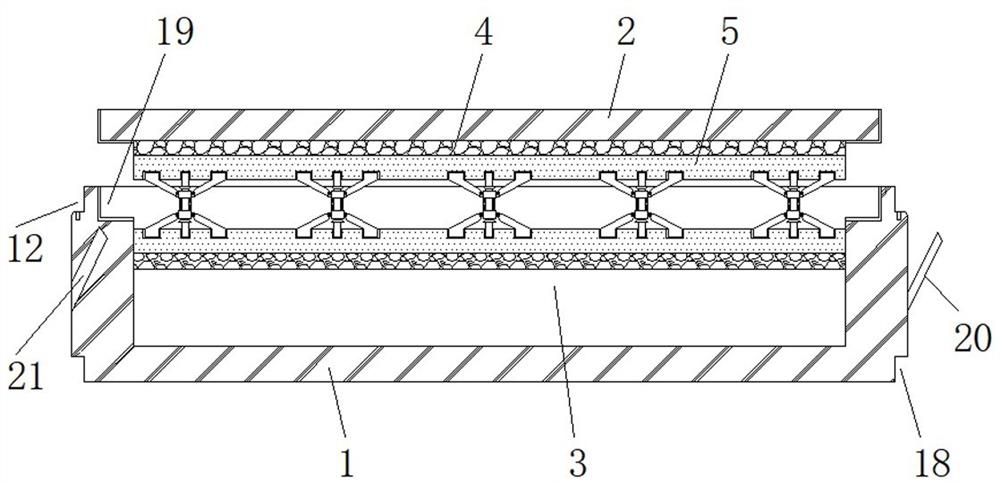

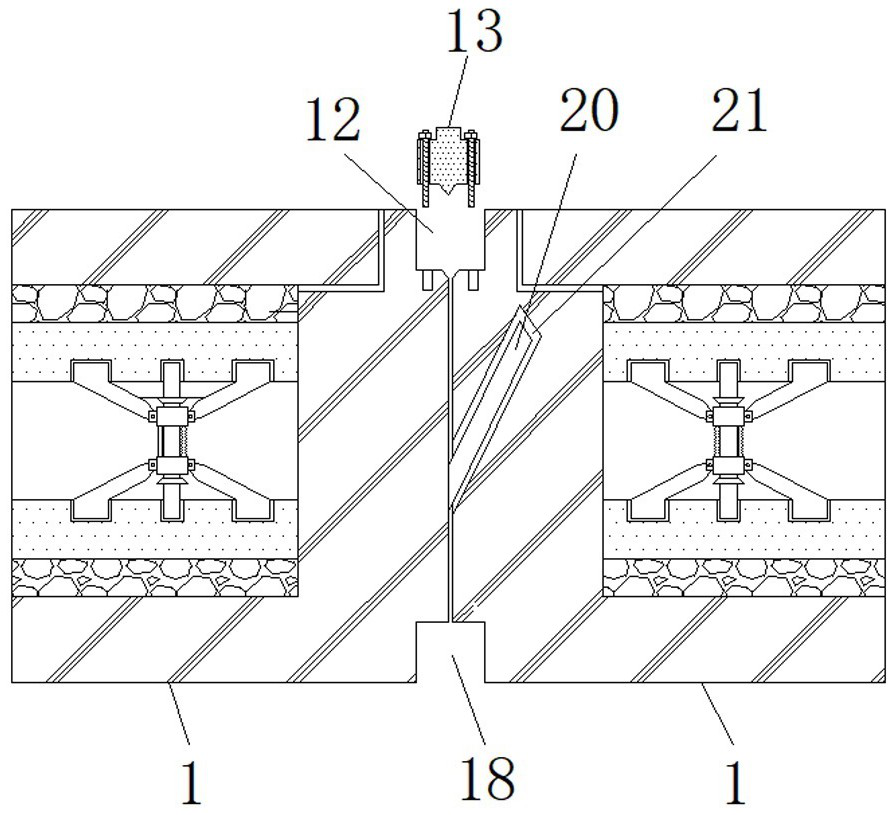

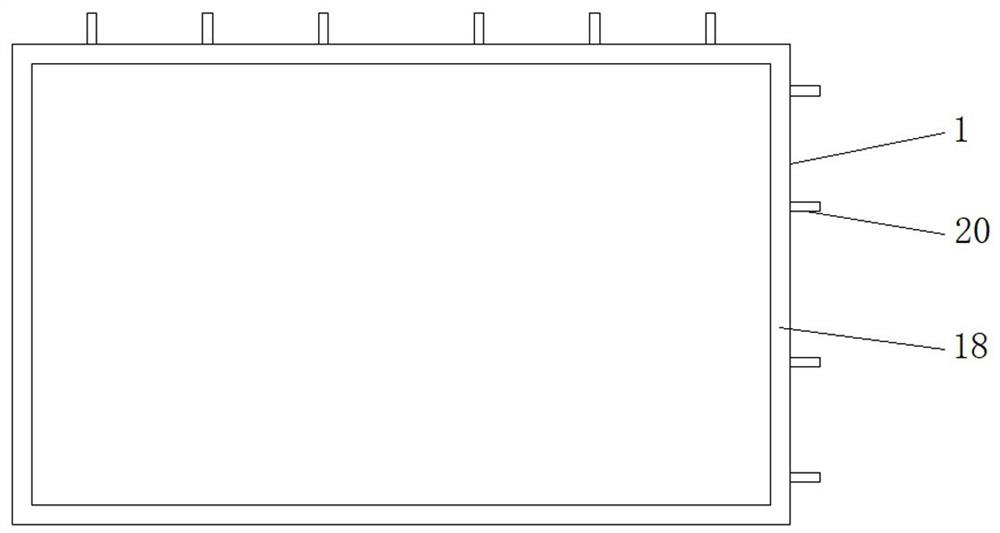

[0034] Such as figure 1 A new type of high-strength thermal insulation board is shown, including an outer panel shell 1 and a cover plate 2 adhered to the top of the outer panel shell 1. The outer panel shell 1 and the cover plate 2 are made of thermal insulation materials, and the outer panel shell The top of the body 1 is provided with a cavity 3 sunken to its inner side, and the inner side of the cavity 3 is provided with a strengthening mechanism installed on the cover plate 2 and can enhance the thermal insulation, sound insulation and compressive performance of the insulation board;

[0035] Such as figure 1 As shown, the top of the outer plate shell 1 is provided with a lap joint 19 with a size larger than that of the cavity 3, and the cover plate 2 is glued to the lap joint 19, and when the cover plate 2 is connected to the lap joint 19, its top surface is in contact with the outer joint 19. The top surface of the plate shell 1 is flush, and the cavity 3 is in a seale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com