Gas diffusion layer, preparation method thereof and fuel cell

A gas diffusion layer and fuel cell technology, applied in fuel cells, battery electrodes, circuits, etc., can solve problems such as shortening process development time, reducing fuel cell gas resistance, membrane electrode flooding and uneven reaction gas transfer, etc. The effect of shortening process development time, saving production and preparation costs, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

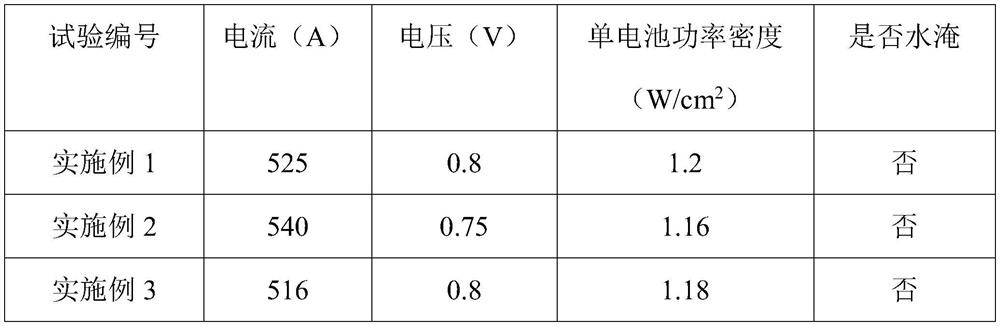

Embodiment 1

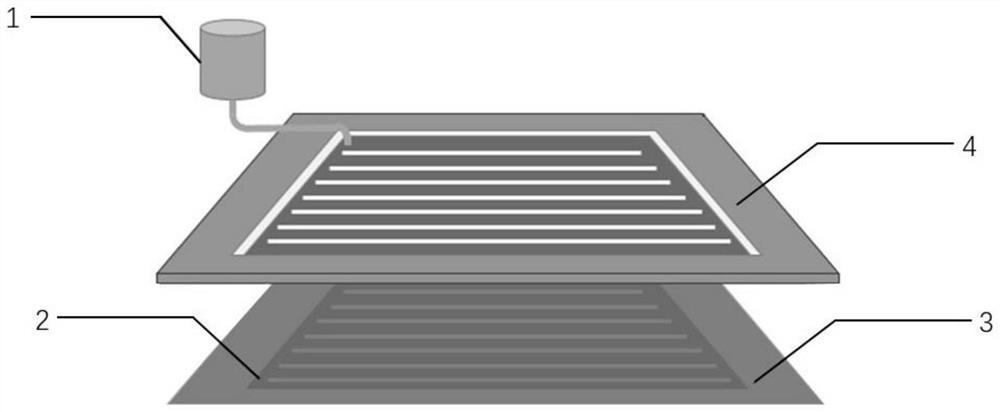

[0063] This embodiment provides a gas diffusion layer, the density of the gas diffusion layer is 55g / cm 2 , the gas diffusion layer includes a stacked short carbon fiber skeleton layer and a porous layer; the porosity of the short carbon fiber skeleton layer is 80%, and the porous layer includes air-permeable materials and water-conducting materials interlaced.

[0064] The thickness of the water-conducting material is 62 μm, and the thickness of the air-permeable material is 44 μm.

[0065] The preparation method of the gas diffusion layer comprises the following steps:

[0066] (1) Use short carbon fiber materials to mix materials, and obtain the skeleton layer through paving, water repelling, curing and fixing the fiber skeleton layer;

[0067] (2) Divide the water-conducting material into 8 times and apply it on the framework layer obtained in step (1), and vacuum-dry it at 105° C. to obtain a composite layer;

[0068] (3) Scrape-coat the water-permeable material on the ...

Embodiment 2

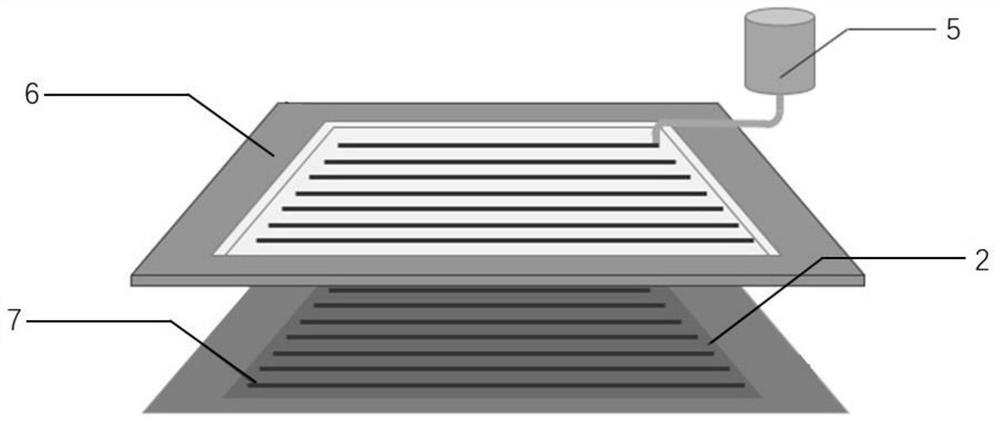

[0073] This embodiment provides a gas diffusion layer, the density of the gas diffusion layer is 30g / cm 2 , the gas diffusion layer includes a stacked short carbon fiber skeleton layer and a porous layer; the porosity of the short carbon fiber skeleton layer is 75%, and the porous layer includes air-permeable materials and water-conducting materials interlaced.

[0074]The thickness of the water-conducting material is 100 μm; the thickness of the breathable material is 50 μm.

[0075] The preparation method of the gas diffusion layer comprises the following steps:

[0076] (1) Use short carbon fiber materials to mix materials, and obtain the skeleton layer through paving, water repelling, curing and fixing the fiber skeleton layer;

[0077] (2) Scrape-coat the water-conducting material once on the skeleton layer obtained in step (1), and vacuum-dry it at 115°C to obtain a composite layer;

[0078] (3) Scrape-coat the water-permeable material once on the composite layer obtai...

Embodiment 3

[0083] This embodiment provides a gas diffusion layer, the density of the gas diffusion layer is 60g / cm 2 , the gas diffusion layer includes a stacked short carbon fiber skeleton layer and a porous layer; the porosity of the short carbon fiber skeleton layer is 95%, and the porous layer includes air-permeable materials and water-conducting materials interlaced.

[0084] The thickness of the water-conducting material is 25 μm, and the thickness of the air-permeable material is 10 μm.

[0085] The preparation method of the gas diffusion layer comprises the following steps:

[0086] (1) Use short carbon fiber materials to mix materials, and obtain the skeleton layer through paving, water repelling, curing and fixing the fiber skeleton layer;

[0087] (2) Divide the water-conducting material into 10 times and scrape-coat it on the framework layer obtained in step (1), and vacuum-dry it at 95°C to obtain a composite layer;

[0088] (3) Scrape-coat the water-permeable material on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com