Method for coating turbomachine guide vane and associated guide vane

A turbine engine and blade technology, which is applied in the coating field of turbine engine guide vanes, can solve problems such as large aerodynamic loss, and achieve the effect of improving aerodynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The drawings are for illustrative purposes and do not limit the invention in any way.

[0042] Unless otherwise stated, identical elements appearing in different figures have a single reference number.

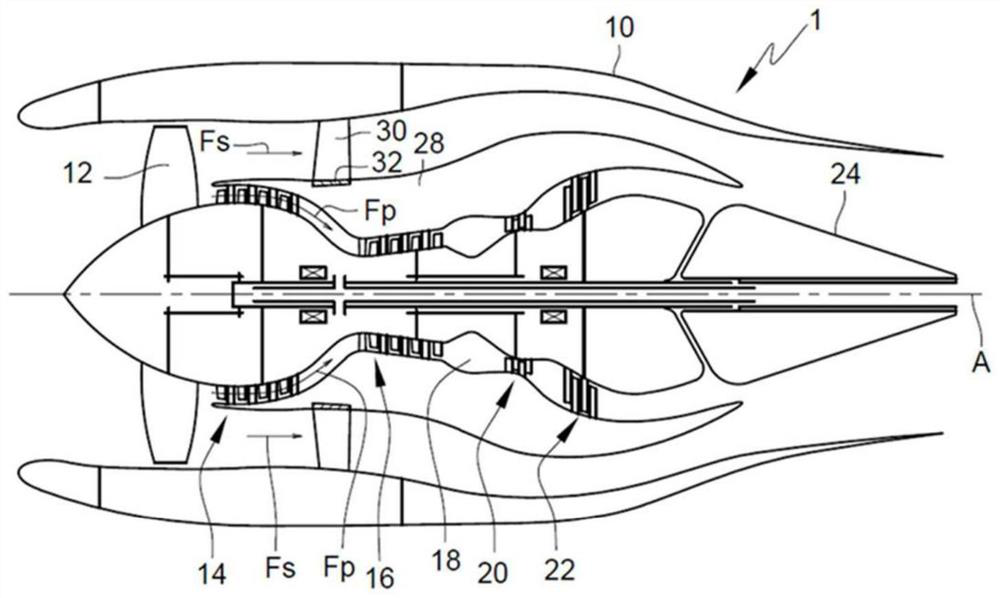

[0043] figure 1 A schematic view of the longitudinal interface of the bypass turbine engine 1 is shown.

[0044] In the remainder of the present description, the terms “inner” and “outer”, “axial” and “radial” and their derivatives are defined relative to the longitudinal axis A of the turbine engine 1 .

[0045] refer to figure 1 , the bypass turbine engine 1 has a longitudinal axis A and includes a casing 10, in which a fan 12, a low-pressure compressor 14, a high-pressure compressor 16, a combustion chamber 18, a high-pressure turbine 20, a low-pressure turbine are arranged from upstream to downstream. 22 and exhaust cone 24. An inner casing 28 is disposed within the outer casing 10 surrounding the compressors 14 and 16 and the turbines 20 and 22 of the combustor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com