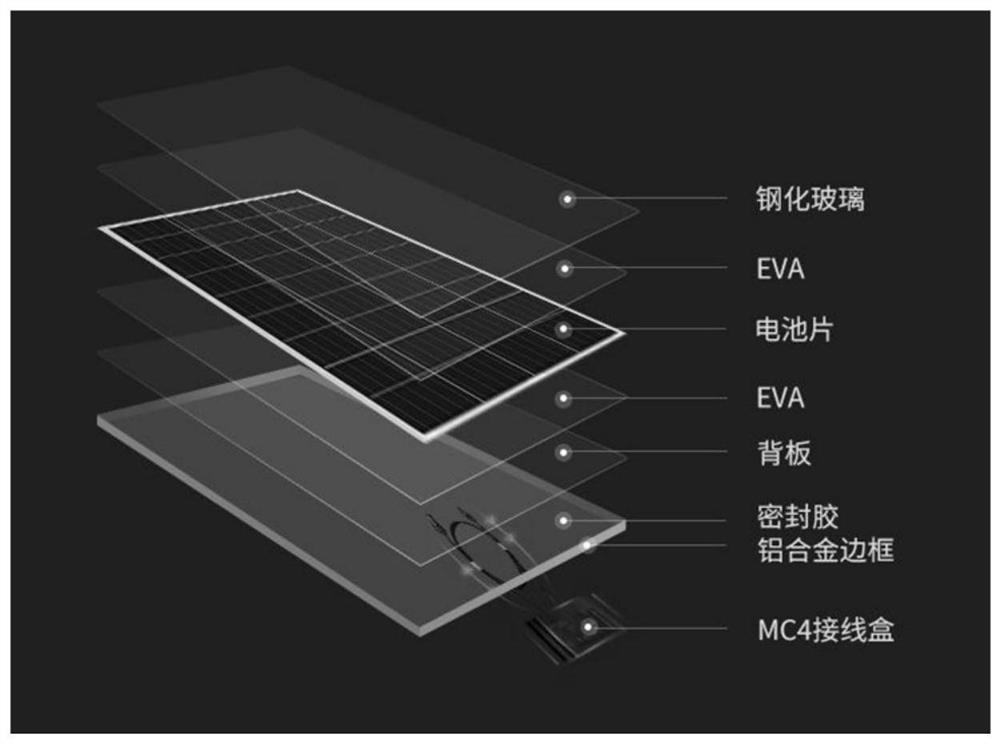

Method for separating and recycling leftover materials of composite EVA (Ethylene Vinyl Acetate) adhesive film of solar back panel based on low-temperature grinding method

A technology of solar back sheet and low temperature grinding, applied in the field of polymer material recycling, can solve the problems of inability to dissociate EVA hot-melt adhesive film, a large amount of waste liquid, etc., and achieve the effect of effective separation and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Grind the solar backplane composite EVA film scraps into 800-mesh powder by a disc grinder at -30°C;

[0021] (2) Choose BaCl 2 The aqueous solution is used as the centrate, and the density of the centrate at 5°C is adjusted to 1.2 g / cm 3 ;

[0022] (3) Add 100 parts by weight of the powder obtained in (1) and 200 parts by weight of water into a centrifuge, centrifuge at 10 rpm for 0.1 minute, let stand for 0.1 hour, and separate the EVA film; The material and 200 parts by weight of the centrifuged liquid obtained in (2) were put into a centrifuge, centrifuged at 10 rpm for 0.1 minute, and allowed to stand for 0.1 hour to separate the fluorine-containing material and the PET material.

Embodiment 2

[0024] (1) Grind the leftovers of solar backplane composite EVA film into 50-mesh powder at 5°C with a rotating shaft grinder;

[0025] (2) Select CaCl 2 High saline solution is used as the centrifugal separation liquid, and the density of the centrifugal separation liquid at 80°C is adjusted to 2.0g / cm 3 ;

[0026] (3) Put 100 parts by weight of the powder obtained in (1) and 2,000 parts by weight of water into a centrifuge, centrifuge at 20,000 rpm for 60 minutes, let it stand for 100 hours, and separate the EVA film; Add 30 parts by weight of the centrifuged liquid obtained in (2) into a centrifuge, centrifuge at 20,000 rpm for 60 minutes, and let stand for 100 hours to separate the fluorine-containing material and the PET material.

Embodiment 3

[0028] (1) Grind the solar backplane composite EVA film scraps into 400-mesh powder through a central hole grinder at -15°C;

[0029] (2) Select KCl high-salt solution as the centrifugation liquid, and adjust the density of the centrifugation liquid at 20°C to 1.5g / cm 3 ;

[0030] (3) Add 100 parts by weight of the powder obtained in (1) and 500 parts by weight of water into a centrifuge, centrifuge at 10,000 rpm for 5 minutes, and after standing for 0.5 hours, separate the EVA film; The material and 2000 parts by weight of the centrifuged liquid obtained in (2) were put into a centrifuge, centrifuged at 10,000 rpm for 5 minutes, and left to stand for 0.5 hours to separate the fluorine-containing material and the PET material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com