Octanal diuracil as well as preparation method and application thereof

A technology of octanal diuracil and dimethyl uracil, which is applied in the field of PVC calcium zinc heat stabilizers, can solve the problems of PVC sheet yellowing, etc., and achieve high initial whiteness, good thermal stability, dynamic and static thermal stability The effect of prolonged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Dissolve 69 parts by weight of DAU in deionized water, and perform magnetic stirring in a 35°C oil bath to completely dissolve the DAU, vacuumize the flask, and then fill it with nitrogen, repeat 3 times, and then fill it with nitrogen protection. 31 parts by weight of octanal was dropped into the flask by using a constant pressure dropping funnel, and the reaction was fully stirred for 48 hours. After the reaction, the precipitate was filtered out with suction, washed three times with deionized water, and dried in a vacuum oven at 45° C. to obtain the octanal bisuracil product (OSU for short).

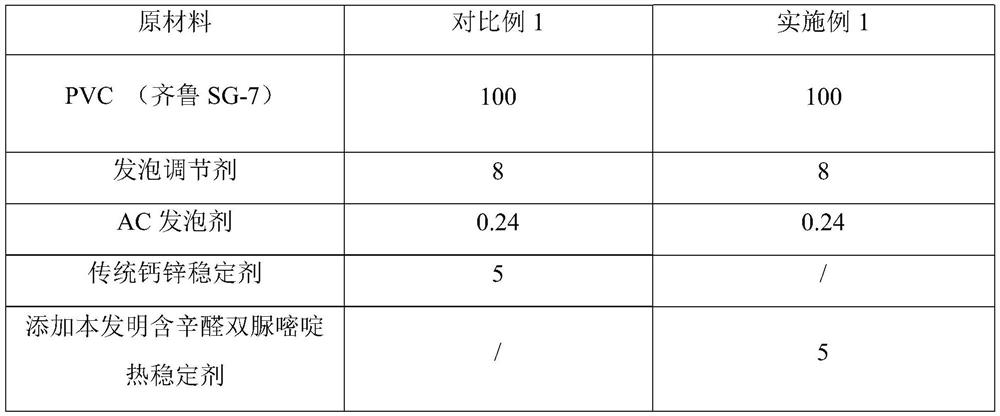

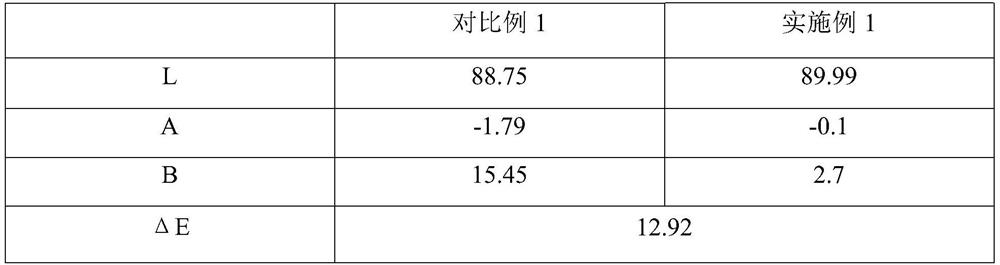

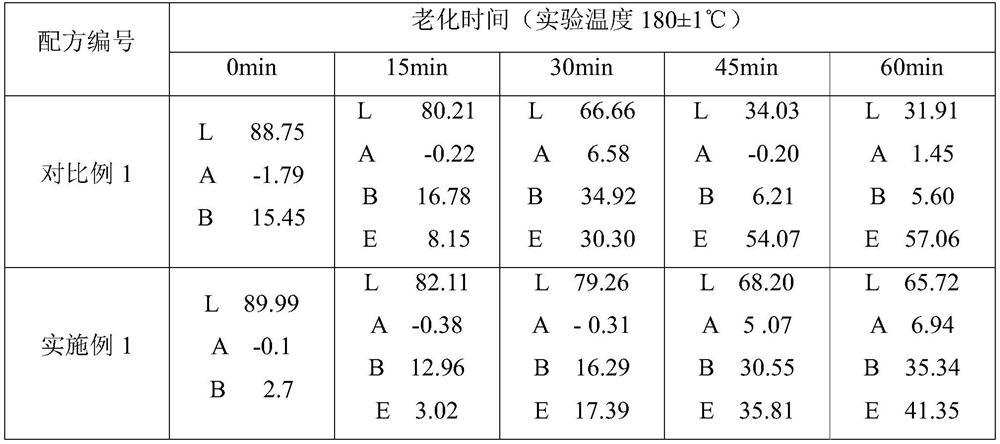

[0027] Using the environmentally friendly nitrogen-containing PVC heat stabilizer octylaldiuracil for PVC bathroom foam board products produced in Example 1, the traditional calcium-zinc stabilizer was used as a comparative example, and PVC bath foam boards were prepared according to the existing process, as shown in the table 1 is the formula comparison (in parts by weight) of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com