Elastic wiredrawing light-cured resin and preparation method thereof, and elastic wiredrawing adhesive

A light-curing resin and elastic technology, which is applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve problems such as poor storage stability, easy gelation, viscoelasticity, and poor brushed appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a method for preparing the elastic drawing photocurable resin described in the above technical solution, comprising the following steps:

[0041] a) under the action of a catalyst, the isocyanate and the polyol react to form a prepolymer of isocyanate;

[0042]b) Under the action of a catalyst, the isocyanate-terminated prepolymer reacts with the hydroxyl acrylic acid monomer to form a double bond-containing prepolymer with a part of the isocyanate reserved;

[0043] c) Mixing and reacting the double-bond-containing prepolymer with reserved part of isocyanate, amine active material and molecular weight modifier to obtain elastic drawing photocurable resin.

[0044] Wherein, the type and amount of the isocyanate, polyol, hydroxyacrylic acid monomer, amine active substance, molecular weight regulator and catalyst are consistent with those described in the above technical solution, and will not be repeated here.

[0045] Regarding step ...

Embodiment 1

[0067] Example 1: Preparation of Elastic Drawing Photocurable Resin

[0068] 1. Raw materials:

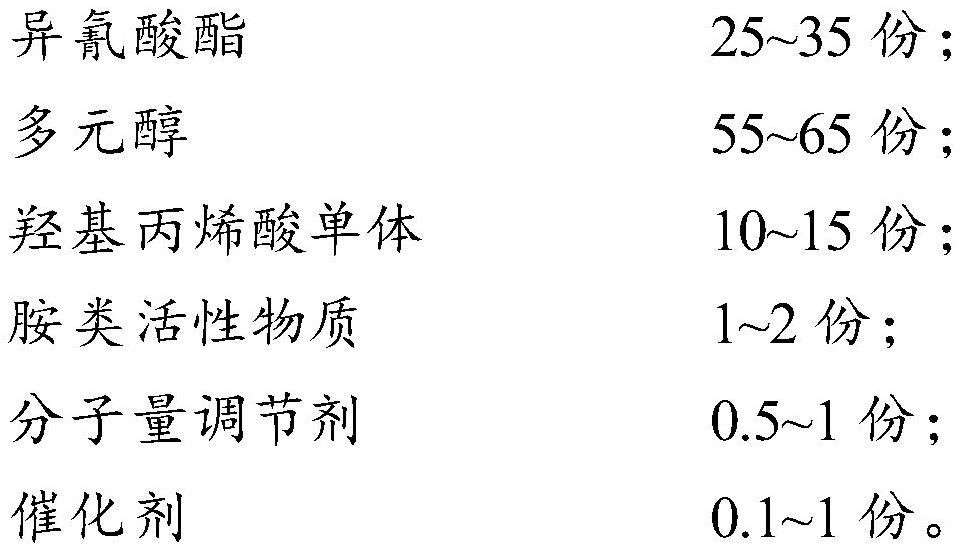

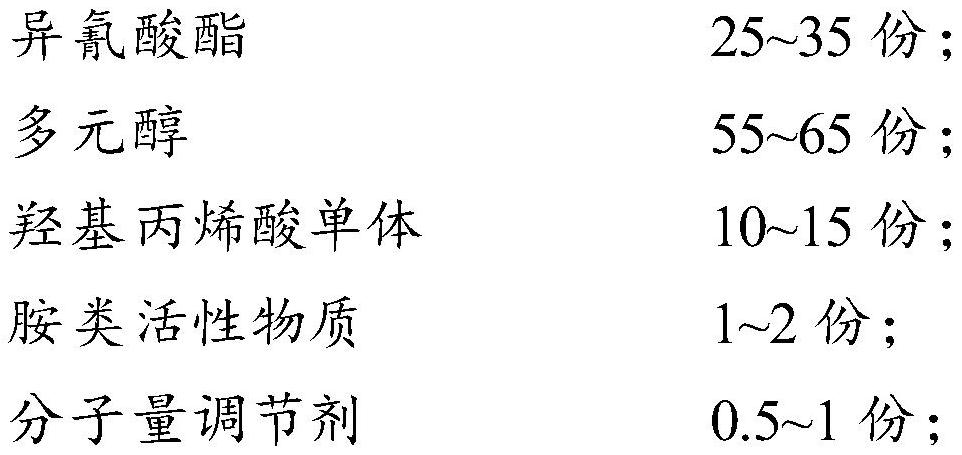

[0069]

[0070] 2. Preparation:

[0071] S1. Put isophorone diisocyanate and catalyst T-12 (0.2 parts) into the reaction flask, heat up to 60°C, and add polyether polyol N210 (M n =1000), and reacted at 60°C for 2 hours to obtain a prepolymer with terminal isocyanate.

[0072] S2. Infuse air, add hydroxyethyl acrylate and catalyst T-12 (0.1 part) dropwise to the obtained isocyanate-terminated prepolymer, and react at 80° C. for 3 hours to obtain a double bond-containing prepolymer with reserved part of isocyanate, Its NCO content = 2.69%.

[0073] S3. Cool down to 40°C the temperature of the double bond-containing prepolymer obtained in step S2 with reserved part of the isocyanate, add isophorone diamine and molecular weight regulator HC5320, and react at 40°C for 2 hours to obtain an elastic drawing photocurable resin.

Embodiment 2

[0074] Example 2: Preparation of Elastic Drawing Photocurable Resin

[0075] Implementation according to Example 1, the difference is that the isophorone diisocyanate in step S1 is replaced by dicyclohexylmethane diisocyanate (H 12 MDI), the polyether polyol was replaced by polyester polyol XCP-355 of equal quality (Asahikawa Chemical).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com