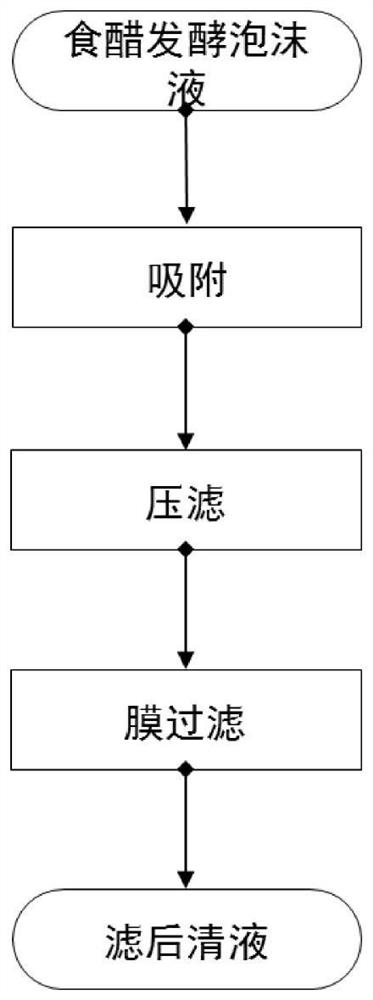

Treatment method of table vinegar fermentation foam liquid

A technology of fermentation foam and processing method, which is applied to the processing field of vinegar fermentation foam liquid, can solve the problems of membrane fouling, antifoaming agent toxicity, foam overflow and the like, and achieves the effects of improving economic value, stable posture and high recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Collect vinegar fermentation foam liquid 50m 3 Add 100kg bentonite, 4kg tannin and 1.5kg pectinase to the stainless steel storage tank through the feeding port, start stirring for 15 minutes, let it stand for adsorption for 48 hours, and start stirring for 10 minutes every 3 hours during this period. After the adsorption is finished, pump it to the plate and frame filter press for press filtration. The filter aid is diatomite, and the diatomite of 50 mesh and 300 mesh is matched in a ratio of 3:1, and the dosage is 4% of the volume of the foam liquid ( kg / m 3 , m / v), the filtered supernatant received 47.2m 3 , The turbidity was detected as 1.0NTU. The ultrafiltration membrane with a molecular weight of 100kDa was used for ultrafiltration, and the concentration ratio was set to 12:1, and the ultrafiltrate was collected at 43m 3 , the recovery rate reached 86.0%, and the turbidity was 0.1NTU. The ultrafiltrated liquid is clear and transparent, and it has not returned ...

Embodiment 2

[0043] Collect vinegar fermentation foam liquid 50m 3 Add 200kg bentonite, 6kg tannin and 3.5kg pectinase to the stainless steel storage tank through the feeding port, start stirring for 15 minutes, let it stand for adsorption for 24 hours, and start stirring for 10 minutes every 3 hours during this period. After the adsorption is finished, pump it to a plate and frame filter press for press filtration. The filter aid is diatomite, and the diatomite of 50 mesh and 300 mesh is matched in a ratio of 3:1, and the dosage is 3% of the volume of the foam liquid ( kg / m 3 , m / v), the filtered supernatant received 48.3m 3 , The turbidity was detected as 0.7NTU. The ultrafiltration membrane with a molecular weight of 100kDa is used for ultrafiltration, and the concentration ratio is set to 12:1, and the ultrafiltrate is 44.6m 3, the recovery rate reached 89.2%, and the turbidity was 0.1NTU. The ultrafiltrated liquid is clear and transparent, and it has not returned to muddy after be...

Embodiment 3

[0045] Collect vinegar fermentation foam liquid 50m 3 Add 200kg bentonite, 6kg tannin and 3.5kg pectinase to the stainless steel storage tank through the feeding port, start stirring for 15 minutes, let it stand for adsorption for 48 hours, and start stirring for 10 minutes every 3 hours during this period. After the adsorption is finished, pump it to the plate and frame filter press for press filtration. The filter aid is diatomite, and the diatomite of 50 mesh and 300 mesh is matched in a ratio of 3:1, and the dosage is 2% of the volume of the foam liquid ( kg / m 3 , m / v), the filtered supernatant received 48.7m 3 , The turbidity was detected as 0.5NTU. The ultrafiltration membrane with a molecular weight of 100kDa is used for ultrafiltration, the concentration ratio is set to 12:1, and the ultrafiltrate is collected at 45.0m 3 , the recovery rate reached 90.0%, and the turbidity was 0.1NTU. The ultrafiltrated liquid is clear and transparent, and it has not returned to mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com