Method for preparing crystalline barium stannate film by using magnetic field enhancement technology

A technology of crystalline barium stannate and barium stannate, which is applied in the field of preparation of crystalline barium stannate thin films, can solve the unfavorable industrialization of strontium titanate substrates, low deposition rate, and unsuitable functional films of crystalline barium stannate The needs of industrialization and other issues, to achieve the effect that is conducive to the promotion of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

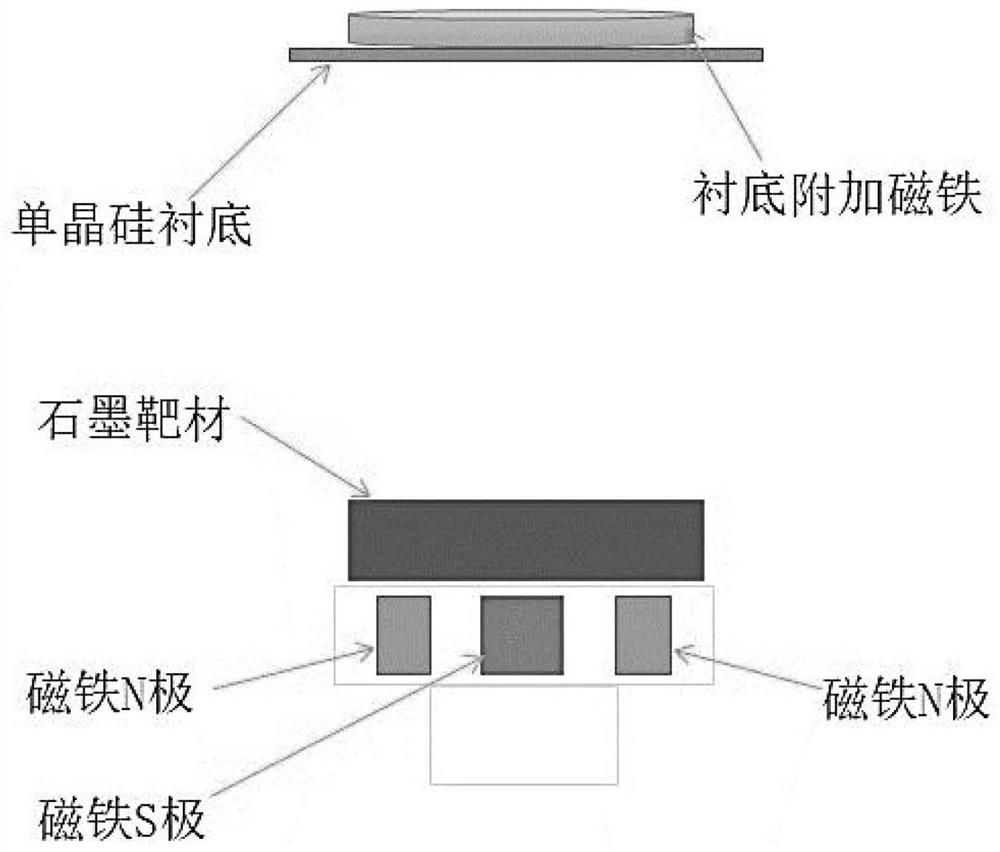

[0024] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0025] During specific implementation, proceed as follows: 1, substrate cleaning:

[0026] Cut quartz, glass, silicon wafer and other substrates into not less than 1×1cm 2 Size, put it into absolute alcohol in a beaker, then use an ultrasonic machine to ultrasonically clean it for 5-10 minutes, dry it with dry air, and put it into a magnetron sputtering vacuum chamber.

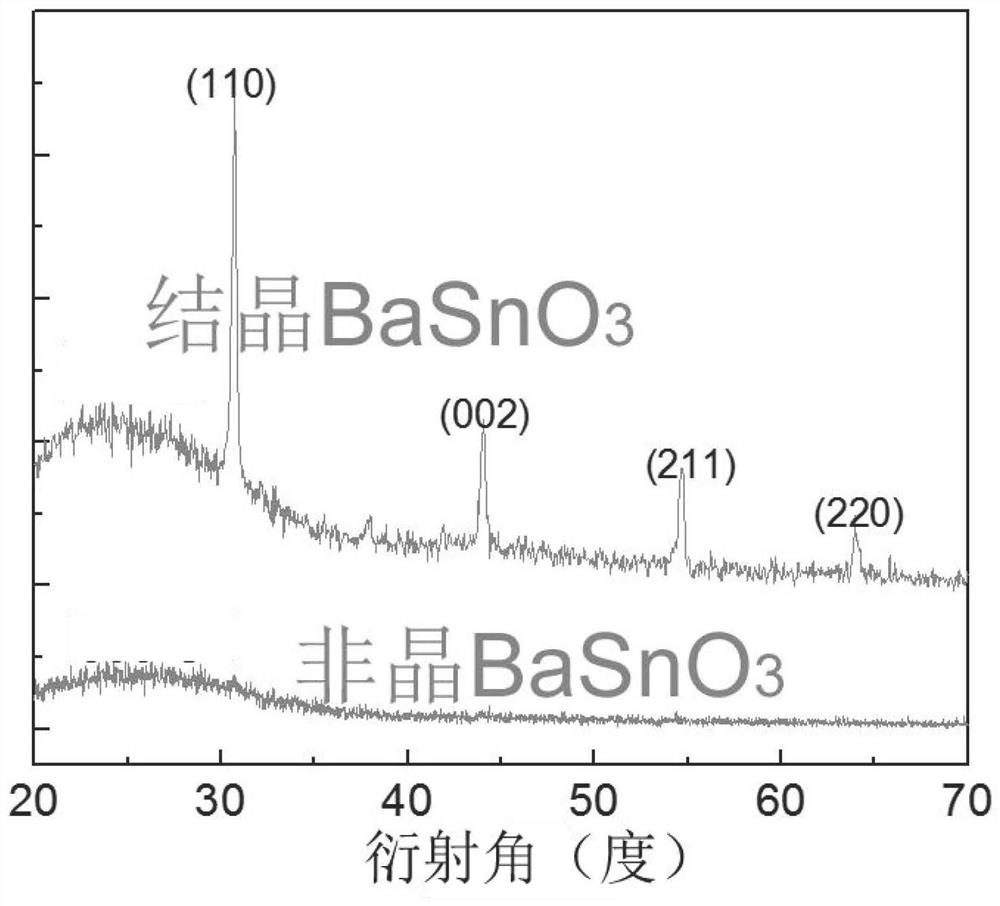

[0027] 2. Magnetron sputtering coating at room temperature to obtain amorphous barium stannate film:

[0028] 2.1 Use mechanical pump and molecular pump to evacuate, so that the background vacuum of the vacuum chamber is better than 2×10 -4 Pa;

[0029] 2.2 Then pre-sputter the barium stannate ceramic target for 10 minutes. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com