Manufacturing method of shield gate trench type semiconductor device

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as high costs and achieve the effect of reducing process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

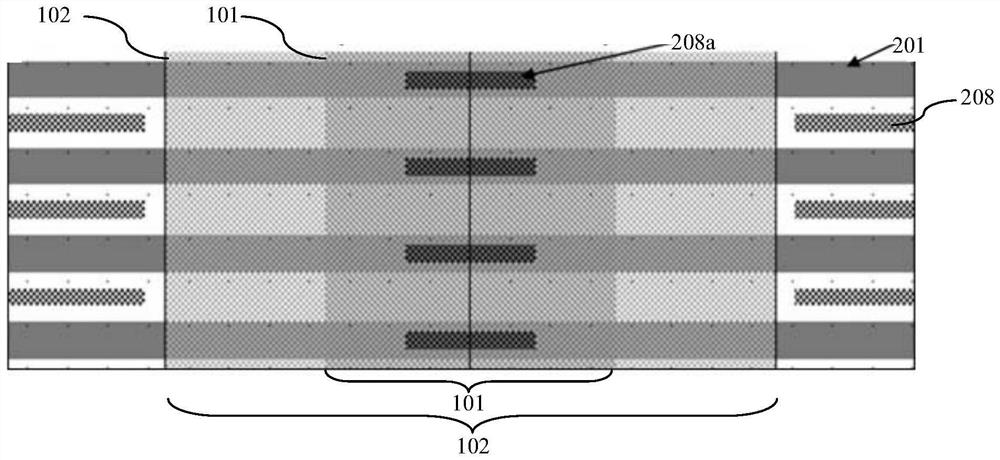

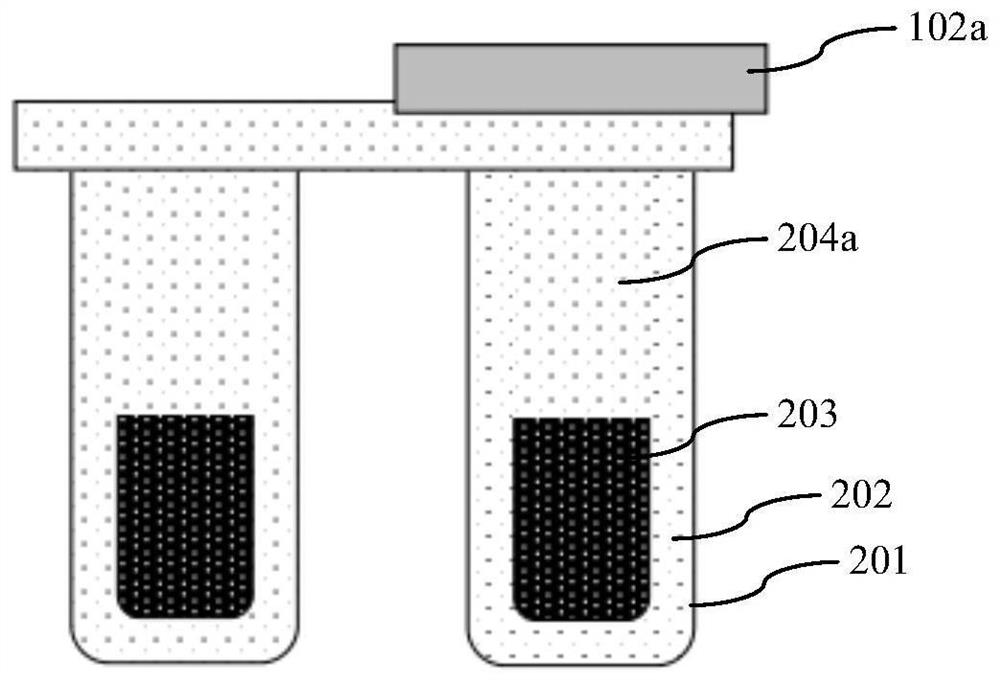

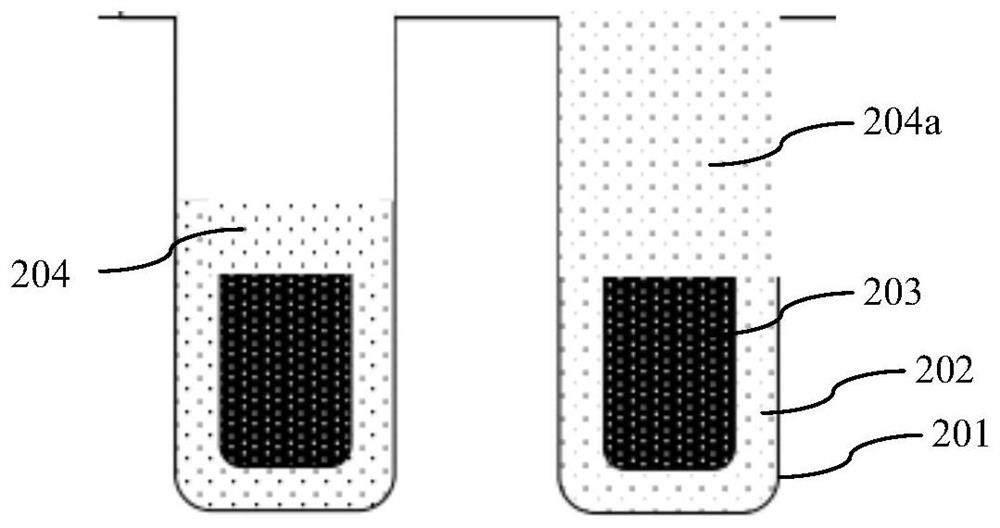

[0072] Such as image 3 As shown, it is a flow chart of the manufacturing method of the shielded gate trench 401 type semiconductor device according to the embodiment of the present invention; Figure 4 As shown, it is the layout structure adopted by the manufacturing method of the shielded gate trench 401 type semiconductor device according to the embodiment of the present invention; Figure 4A shown, is Figure 4 Enlarged view of the lead-out structure of Zhongyuan polysilicon; Figure 5A to Figure 5F As shown, it is a schematic diagram of the device structure in each step of the manufacturing method of the shielded gate trench 401 type semiconductor device according to the embodiment of the present invention; the manufacturing method of the shielded gate trench 401 type semiconductor device according to the embodiment of the present invention includes the following steps:

[0073] Step 1, such as Figure 5A As shown, a plurality of trenches are formed on a semiconductor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com