Laser processing device, processing equipment and processing method

A laser processing and laser technology, which is applied in the direction of laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problem that the cutting production capacity of solar cells needs to be further improved, and achieve the goal of saving cutting time, increasing cutting production capacity and saving work stations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

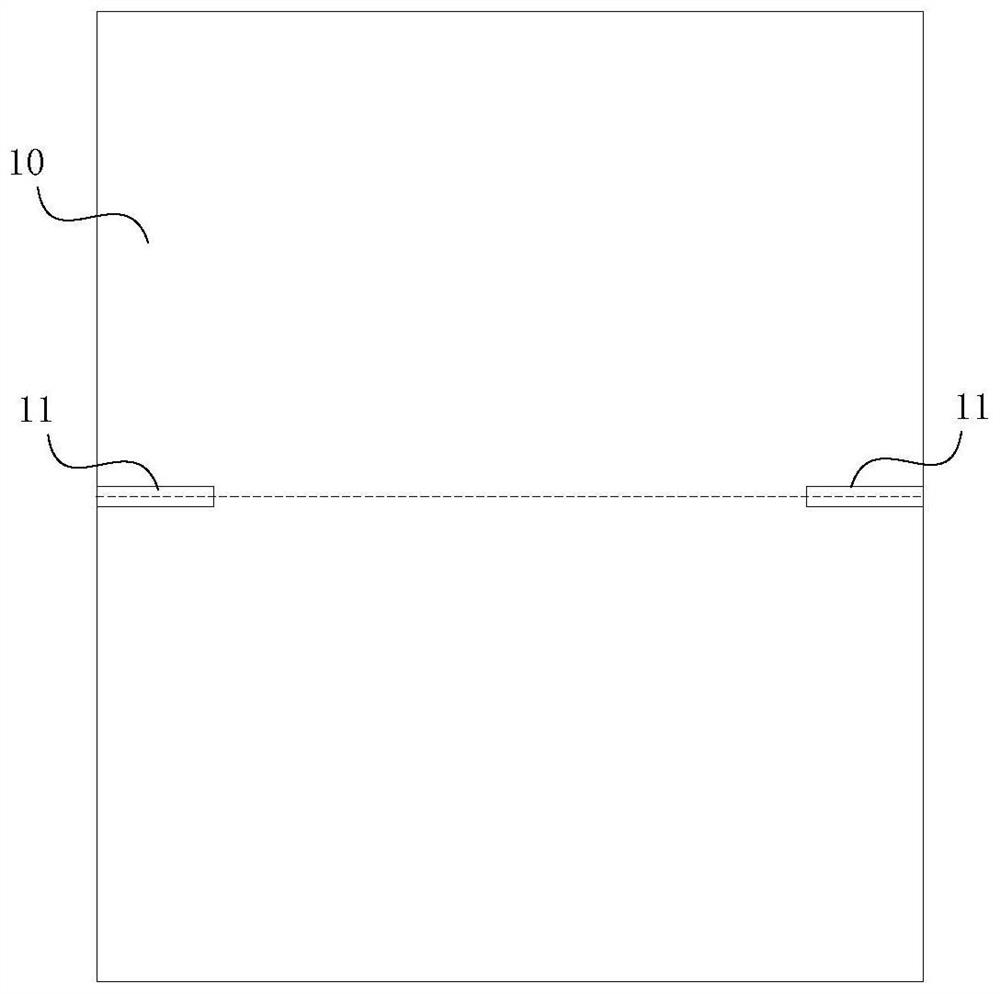

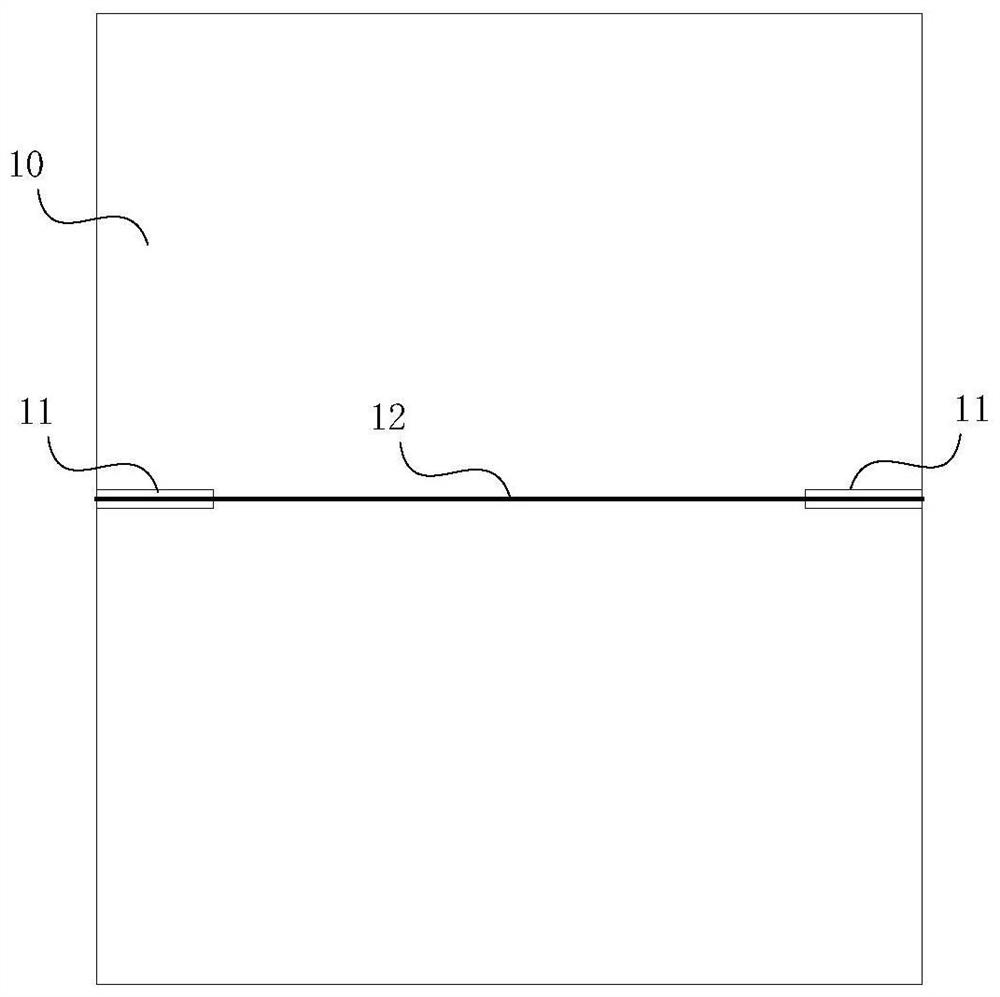

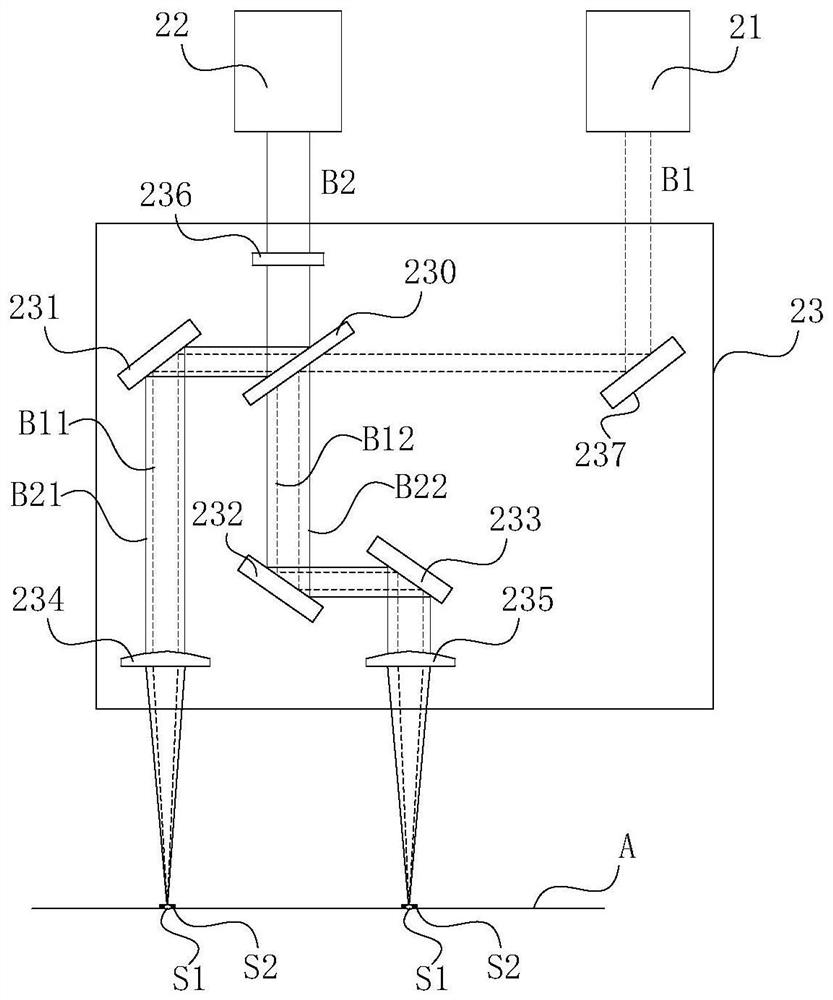

[0095] As in the background art, the cutting capacity of existing solar cells needs to be further improved. The inventors found that, if figure 1 As shown, in the prior art, the first laser is used at the first station to form the cutting groove 11 at the beginning and the end of the path to be cut of the solar cell sheet 10, and then as shown in FIG. figure 2 As shown in the second station, the second laser (thermal stress laser) is used to scan along the path to be cut to form the cutting line 12, so that the solar cell sheet 10 is split (that is, the second laser scans along the path to be cut to provide heat) Gradient, the device to be cut produces microcracks along the cutting groove 11 and extends to make the device to be cut crack along the path to be cut, that is, the cutting line 12), and the reason for the low production capacity is mainly that the first laser and the second laser The two stations alternately cut the solar cells 10 , making the cutting process long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com