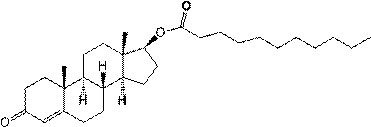

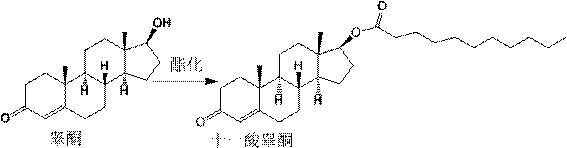

Preparation method of high-purity testosterone undecanoate

A high-purity technology of testosterone undecanoate, applied in the field of steroid drug preparation, can solve the problems of large amount of waste water, high cost of raw materials and low purity of testosterone undecanoate, etc., and achieves the effects of low solvent cost and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Pump 500g of dichloromethane and 100g of triethylamine into the reaction bottle, then add 100g of testosterone, stir evenly, start to add 200g of undecanoyl chloride dropwise, after the dropwise addition, keep the reaction at 0°C for 2 hours, monitor by TLC until the raw materials react completely;

[0023] (2) After the reaction of the raw materials in step (1), add 100g of 6N hydrochloric acid solution and stir for 40min, let it stand for 15min, and remove the water layer; wash the dichloromethane layer with water 3 times until neutral, each time with 200ml of water; 35°C under negative pressure Concentrate dichloromethane until it is concentrated without solvent; pump in 100g of methanol, stir and cool down to 0°C, and crystallize for 4h; suction filter, drain and discharge to obtain 153g of crude testosterone undecanoate;

[0024] (3) Add 800g of methanol, 3g of activated carbon, and 153g of crude testosterone undecanoate prepared in step (1) into the reaction f...

Embodiment 2

[0026] (1) Pump 600g of dichloromethane and 150g of triethylamine into the reaction bottle, then add 100g of testosterone, stir evenly, start to add 300g of undecanoyl chloride dropwise, after the dropwise addition, keep the reaction at 5°C for 1 hour, monitor by TLC until the raw materials react completely;

[0027] (2) After the reaction of the raw materials in step (1), add 120g of 6N hydrochloric acid solution and stir for 30min, let it stand for 20min, and remove the water layer; wash the dichloromethane layer twice to neutral, each time with 300ml of water; 40℃ negative pressure Concentrate dichloromethane until it is concentrated without solvent; pump in 150g of methanol, stir and cool down to -5°C, and crystallize for 2h; suction filter, drain and discharge to obtain 155g of crude testosterone undecanoate;

[0028] (3) Add 1000g of methanol, 5g of activated carbon, and 155g of crude testosterone undecanoate obtained in step (2) into the reaction flask, heat up to reflu...

Embodiment 3

[0030] (1) Pump 550g of dichloromethane and 125g of triethylamine into the reaction bottle, then add 100g of testosterone, stir evenly, start to add 250g of undecanoyl chloride dropwise, after the dropwise addition, keep the reaction at 2.5°C for 1.5h, monitor by TLC until the raw material Complete response;

[0031] (2) After the reaction of the raw materials in step (1), add 110g of 6N hydrochloric acid solution and stir for 35 minutes, let it stand for 17 minutes, and remove the water layer; wash the dichloromethane layer with water twice to neutral, each time with 250ml of water; 37 ℃ negative pressure Concentrate dichloromethane until it is concentrated without solvent; pump in 125g of methanol, stir and cool down to -2.5°C, and crystallize for 3h; suction filter, drain and discharge to obtain 152g of crude testosterone undecanoate;

[0032] (3) Add 900g of methanol, 4g of activated carbon, and 152g of crude testosterone undecanoate prepared in step (2) into the reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com