Composite adhesive film, preparation method thereof and photovoltaic module

A photovoltaic module and composite adhesive technology, applied in photovoltaic power generation, adhesives, electrical components, etc., can solve the problems of high POE price, cell deviation, and difficult POE film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

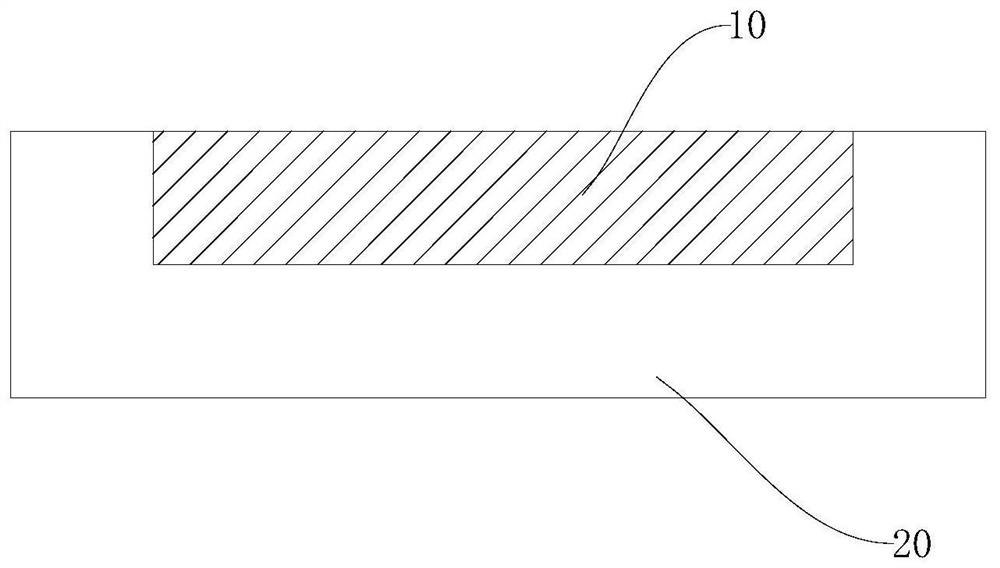

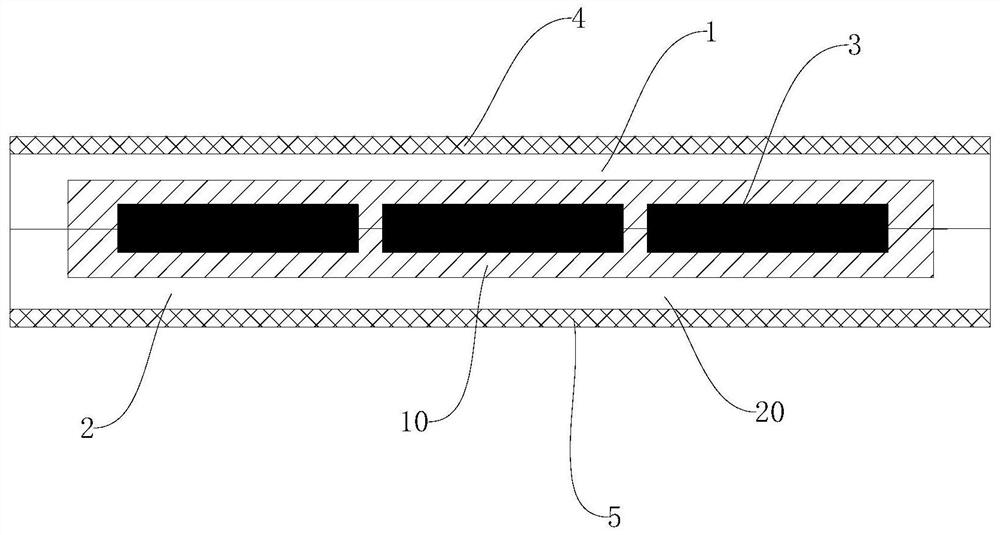

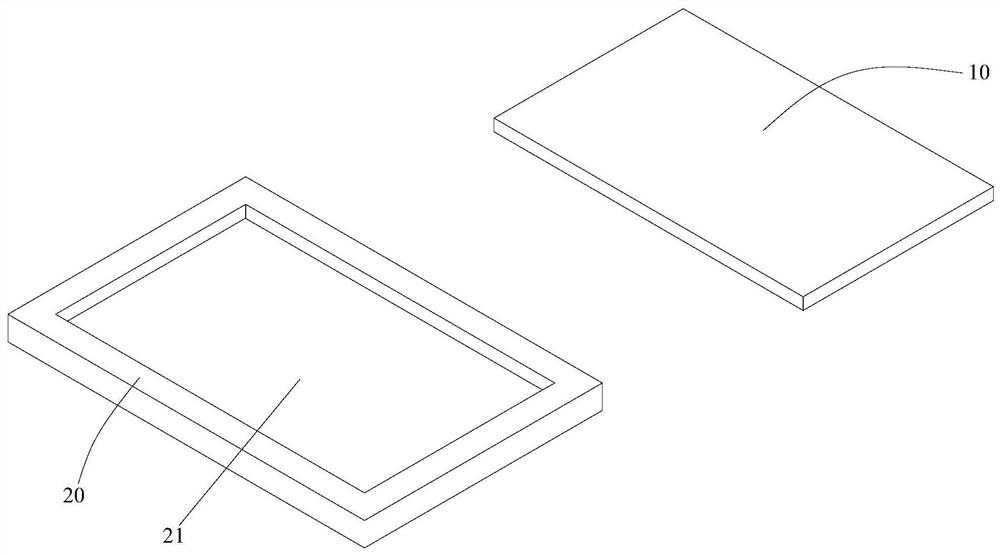

[0036] According to a second aspect of the present invention, the preparation method of the composite film comprises the steps of:

[0037] (1) Stirring of raw materials, stirring the EVA film raw materials and their corresponding additives in the mixing equipment to form evenly stirred EVA film ingredients, stirring the POE film raw materials and their corresponding additives in the mixing equipment to form Stir the POE film ingredients evenly;

[0038] (2) extrusion molding, the uniformly stirred EVA film ingredients are extruded by extrusion equipment to form EVA colloids, and the stirred POE film ingredients are extruded by extrusion equipment to form POE colloids, wherein the EVA colloid and the The POE colloid is in a semi-fluid state, and the EVA colloid and the POE colloid are respectively cut into POE sheets and EVA sheets of the required size, wherein the width of the EVA sheet is smaller than the width of the POE sheet, and the POE The thickness of the sheet is gre...

Embodiment 1

[0049] A preparation method for a composite adhesive film, comprising the steps of:

[0050] (1) Stirring of raw materials, stirring the EVA film raw materials and their corresponding additives in the mixing equipment to form evenly stirred EVA film ingredients, stirring the POE film raw materials and their corresponding additives in the mixing equipment to form Stir the POE film ingredients evenly;

[0051] (2) extrusion molding, the uniformly stirred EVA film ingredients are extruded by extrusion equipment to form EVA colloids, and the stirred POE film ingredients are extruded by extrusion equipment to form POE colloids, wherein the EVA colloid and the The POE colloid is in a semi-fluid state, and the EVA colloid and the POE colloid are respectively cut into POE sheets and EVA sheets of the required size, wherein the width of the EVA sheet is smaller than the width of the POE sheet, and the POE The thickness of the sheet is greater than that of the EVA sheet, the thickness ...

Embodiment 2

[0059] A preparation method for a composite adhesive film, comprising the steps of:

[0060] (1) Stirring of raw materials, stirring the EVA film raw materials and their corresponding additives in the mixing equipment to form evenly stirred EVA film ingredients, stirring the POE film raw materials and their corresponding additives in the mixing equipment to form Stir the POE film ingredients evenly;

[0061] (2) extrusion molding, the uniformly stirred EVA film ingredients are extruded by extrusion equipment to form EVA colloids, and the stirred POE film ingredients are extruded by extrusion equipment to form POE colloids, wherein the EVA colloid and the The POE colloid is in a semi-fluid state, and the EVA colloid and the POE colloid are respectively cut into POE sheets and EVA sheets of the required size, wherein the width of the EVA sheet is smaller than the width of the POE sheet, and the POE The thickness of the sheet is greater than that of the EVA sheet, the thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com