Orange-light carbon dot for rapidly positioning Golgi apparatus based on cyclooxygenase-2 target spot as well as preparation and application of orange-light carbon dot

A cyclooxygenase and Golgi technology, applied in nano-optics, luminescent materials, fluorescence/phosphorescence, etc., can solve the problems of inability to achieve fast and accurate Golgi imaging, limit the efficiency of fluorescence imaging, and achieve accurate Golgi targeting. Effects, high selectivity, small size effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

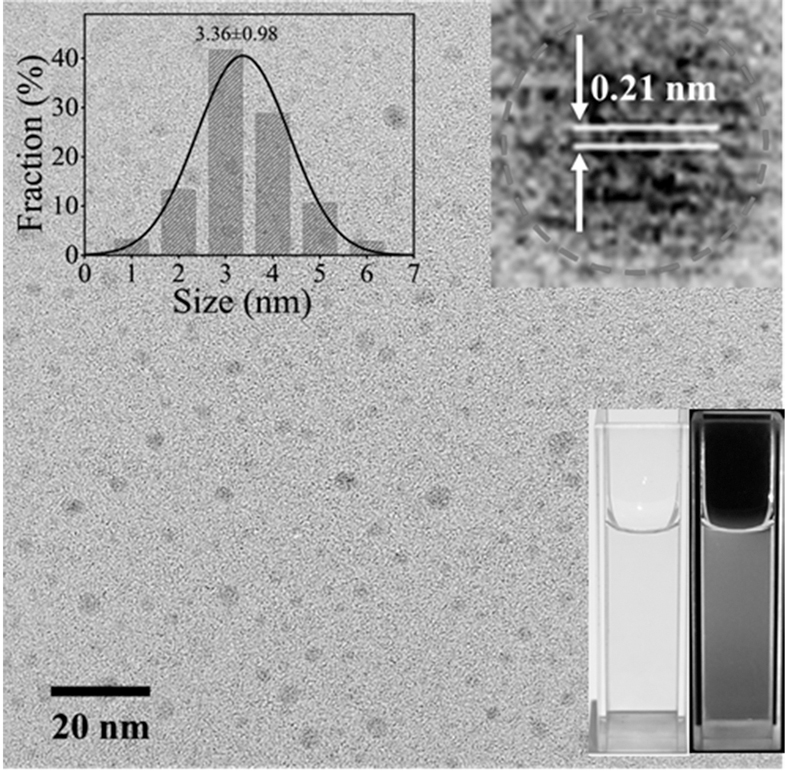

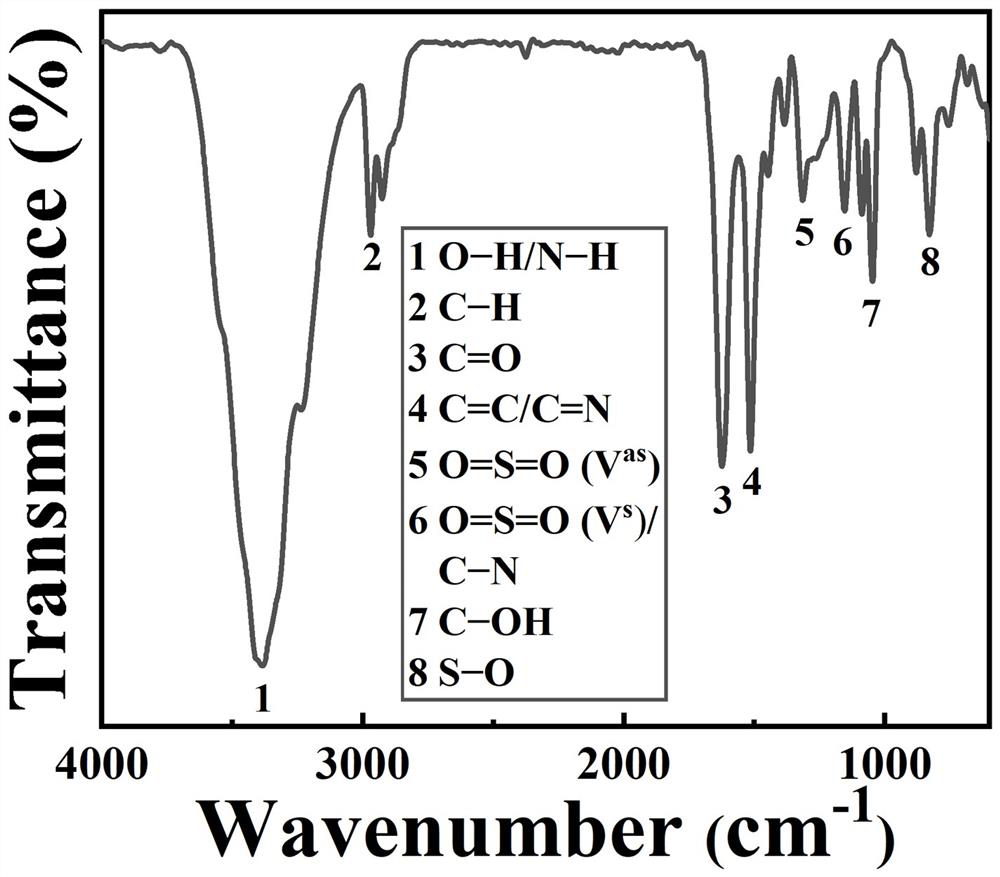

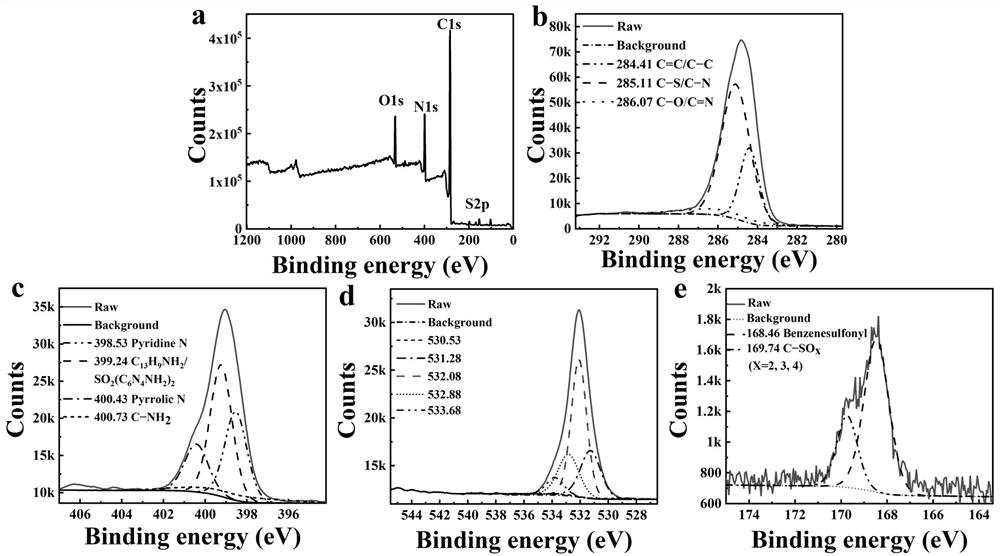

[0050] Weigh 0.0324g of p-phenylenediamine and 0.0157g of benzenesulfonamide, add 40mL of methanol, seal with parafilm, place on an ultrasonic disperser, and ultrasonically disperse at a frequency of 60KHz for 3min to obtain a mixed solution.

[0051] The mixed solution was placed in a stainless steel reaction kettle lined with polytetrafluoroethylene, heated to 180° C. for 8 hours under sealing, and reacted for 8 hours to obtain a wine red solution product.

[0052] Filter the product with a 0.22 μm hydrophilic microporous membrane, then put the filtrate into a dialysis bag with a molecular weight cut-off of 500-1000 Da, dialyze in deionized water for 12 hours, add the dialysate into a rotary steamer, and then add 20 mL Deionized water, heated to 55°C and rotary evaporated to remove methanol, concentrated to about 15mL and stopped rotary evaporation, cooled to room temperature and placed in a -80°C refrigerator to freeze, and then frozen in a vacuum freeze-drying oven at a vac...

Embodiment 2

[0062] Weigh 0.1081g of p-phenylenediamine and 0.1572g of benzenesulfonamide, add 40mL of methanol, seal with a parafilm, place on an ultrasonic disperser, and disperse ultrasonically at a frequency of 60KHz for 5min to obtain a mixed solution.

[0063] The mixed solution was placed in a stainless steel reaction kettle lined with polytetrafluoroethylene, heated to 170° C. for 8.5 hours under sealing, and reacted for 8.5 hours to obtain a wine red solution product.

[0064]Filter the product with a 0.22 μm hydrophilic microporous membrane, then put the filtrate into a dialysis bag with a molecular weight cut-off of 500-1000 Da, dialyze in deionized water for 12 hours, add the dialysate into a rotary steamer, and then add 20 mL Deionized water, heated to 55°C and rotary evaporated to remove methanol, concentrated to about 15mL and stopped rotary evaporation, cooled to room temperature and placed in a -80°C refrigerator to freeze, and then frozen in a vacuum freeze-drying oven at ...

Embodiment 3

[0066] Weigh 0.0960g of p-phenylenediamine and 0.1410g of benzenesulfonamide, add 35mL of methanol, seal with parafilm, place on an ultrasonic disperser, and ultrasonically disperse at a frequency of 60KHz for 3min to obtain a mixed solution.

[0067] The mixed solution was placed in a stainless steel reaction kettle lined with polytetrafluoroethylene, and the temperature was raised to 180° C. for 7 hours of reaction under sealing to obtain a wine red solution product.

[0068] Filter the product with a 0.22 μm hydrophilic microporous membrane, then put the filtrate into a dialysis bag with a molecular weight cut-off of 500-1000 Da, dialyze in deionized water for 12 hours, add the dialysate into a rotary steamer, and then add 20 mL Deionized water, heated to 55°C and rotary evaporated to remove methanol, concentrated to about 15mL and stopped rotary evaporation, cooled to room temperature and placed in a -80°C refrigerator to freeze, and then frozen in a vacuum freeze-drying ov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com