Design method and system for oil smoke exhaust duct

A design method and oil fume exhaust technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of the oil fume exhaust system and the unsuitable method of the flue size, so as to reduce the area occupied by the well and ensure the emission effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

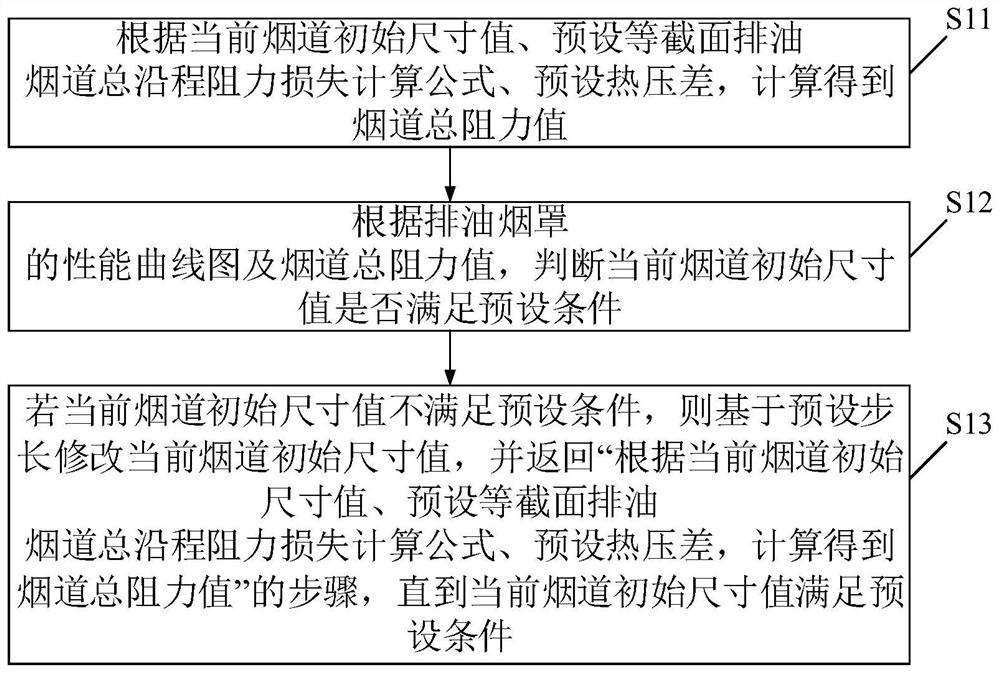

[0033] Embodiments of the present invention provide a method for designing an oil exhaust flue, such as figure 1 As shown, steps S11 to S13 are included, specifically as follows:

[0034] Step S11: Calculate the total resistance value of the flue according to the current initial size value of the flue, the preset formula for calculating the total resistance loss along the process of the equal-section oil discharge flue, and the preset thermal pressure difference.

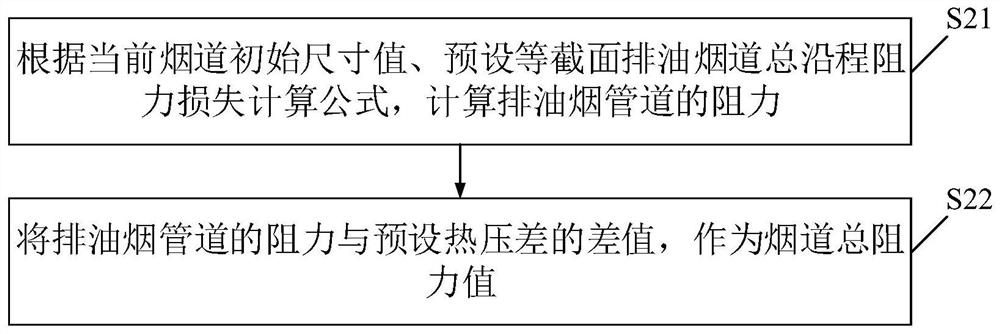

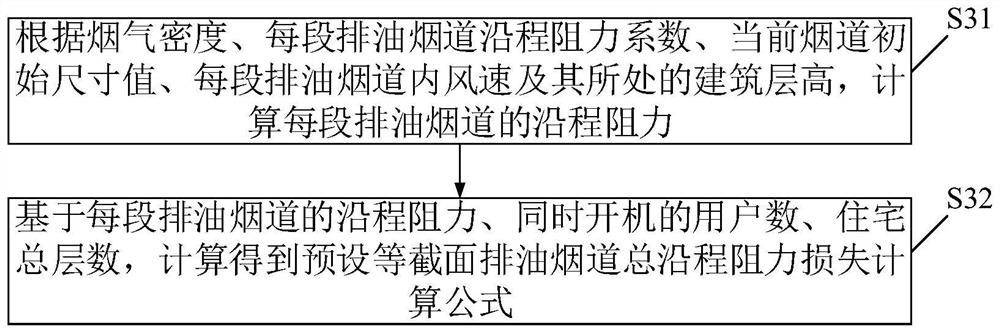

[0035] Specifically, such as figure 2 As shown, obtaining the total resistance value of the flue is performed by specific steps S21 to S22, as follows:

[0036] Step S21: Calculate the resistance of the oil fume exhaust duct according to the current initial size value of the flue and the preset formula for calculating the total resistance loss of the oil exhaust flue with equal cross-section.

[0037] Step S22: The difference between the resistance of the oil fume exhaust pipe and the preset thermal pressure diff...

Embodiment 2

[0101] An embodiment of the present invention provides an oil exhaust flue design system, such as Figure 7 shown, including:

[0102] Calculation module 1 of the total resistance value of the flue, which is used to calculate the total resistance value of the flue according to the current initial size value of the flue, the preset calculation formula of the total resistance loss along the oil discharge flue with equal cross-section, and the preset thermal pressure difference; this module Execute the method described in step S11 in Embodiment 1, which will not be repeated here.

[0103] Judgment module 2, for judging whether the initial size value of the current flue meets the preset condition according to the performance curve diagram of the oil exhaust hood and the total resistance value of the flue; this module executes the method described in step S12 in Embodiment 1, and This will not be repeated here.

[0104] The adjustment module 3 is used to modify the initial size v...

Embodiment 3

[0106] An embodiment of the present invention provides a computer device, such as Figure 8 As shown, it includes: at least one processor 401 , such as a CPU (Central Processing Unit, central processing unit), at least one communication interface 403 , memory 404 , and at least one communication bus 402 . Wherein, the communication bus 402 is used to realize connection and communication between these components. Wherein, the communication interface 403 may include a display screen (Display) and a keyboard (Keyboard), and the optional communication interface 403 may also include a standard wired interface and a wireless interface. The memory 404 may be a high-speed RAM memory (Ramdom Access Memory, volatile random access memory), or a non-volatile memory (non-volatile memory), such as at least one disk memory. Optionally, the memory 404 may also be at least one storage device located away from the aforementioned processor 401 . Wherein, the processor 401 can execute the metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com