Flame-retardant sodium ion battery electrolyte

A sodium-ion battery and electrolyte technology, applied in secondary batteries, organic electrolytes, non-aqueous electrolytes, etc., can solve the problems of scarcity and uneven distribution of lithium resources, reduce internal resistance, ease the increase of internal resistance, and suppress internal resistance. The effect of increased resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

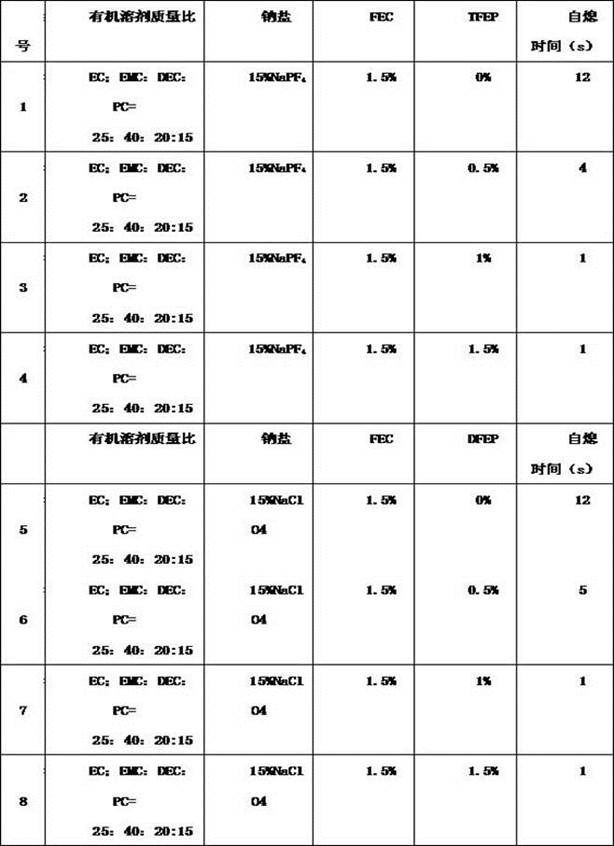

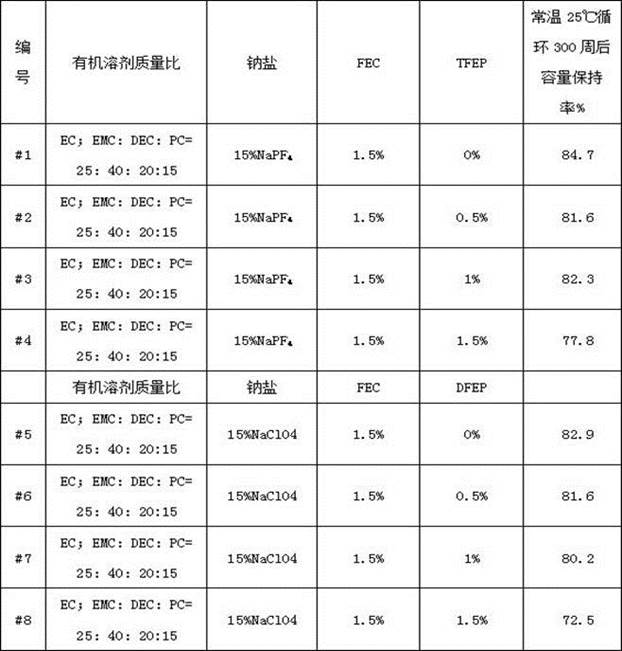

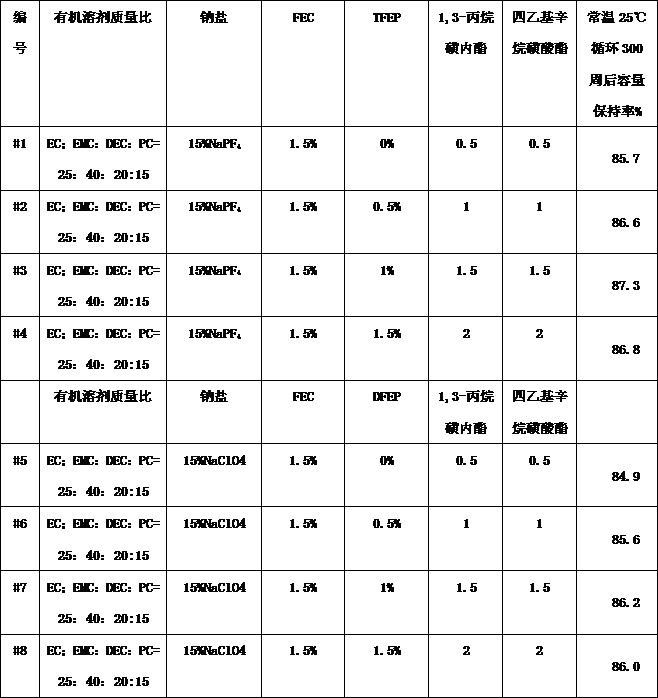

[0025] Embodiment 1: a kind of flame-retardant sodium ion battery electrolyte, comprises organic solvent, sodium salt and additive; Described additive comprises flame-retardant additive and film-forming additive; Described flame-retardant additive comprises three-(2,2,2 - one or both of trifluoroethyl) phosphate and two (2,2,2-trifluoroethyl) methyl phosphate; the film-forming additive is fluoroethylene carbonate; barrier of the present invention Tris-(2,2,2-trifluoroethyl) phosphate and bis(2,2,2-trifluoroethyl) methyl phosphate used in fuel additives will release P-containing or The free radicals of F combine with the free radicals of H to form non-combustible substances and block the chain reaction of combustion, thus effectively flame retardant;

[0026] The film-forming additive of the present invention selects fluoroethylene carbonate instead of conventional vinylene carbonate. After the decomposition of fluoroethylene carbonate, HF can be produced and VC can be produced...

Embodiment 2

[0038] Embodiment 2: A kind of flame-retardant sodium-ion battery electrolyte; Prepared by the following method, at room temperature, in the glove box, ethylene carbonate, ethyl methyl carbonate, diethyl carbonate, and propylene carbonate are configured according to the mass ratio A mixed solvent, dissolving the sodium salt in the mixed solvent, the weight ratio of the sodium salt to the mixed solvent is 15:85, and then adding flame retardant additives and film-forming additives.

[0039] Wherein, the flame retardant additive is 0.5-1.5 parts of tris-(2,2,2-trifluoroethyl) phosphate; the film-forming additive is 1-2 parts of fluoroethylene carbonate; the organic The solvent includes 20-30 parts of ethylene carbonate, 35-45 parts of ethyl methyl carbonate, 15-25 parts of diethyl carbonate and 10-20 parts of propylene carbonate; the sodium salt is 10-20 parts sodium hexafluorophosphate.

Embodiment 3

[0040] Embodiment 3: A kind of flame-retardant sodium-ion battery electrolyte; Prepared by the following method, at room temperature, in a glove box, ethylene carbonate, ethyl methyl carbonate, diethyl carbonate, and propylene carbonate are configured according to the mass ratio A mixed solvent, dissolving the sodium salt in the mixed solvent, the weight ratio of the sodium salt to the mixed solvent is 15:85, and then adding flame retardant additives and film-forming additives.

[0041] Wherein, the flame retardant additive is 0.5 part of tri-(2,2,2-trifluoroethyl) phosphate; the film-forming additive is 1 part of fluoroethylene carbonate; the organic solvent includes 20 Parts of ethylene carbonate, 35 parts of ethyl methyl carbonate, 15 parts of diethyl carbonate and 10 parts of propylene carbonate; the sodium salt is 10 parts of sodium hexafluorophosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com